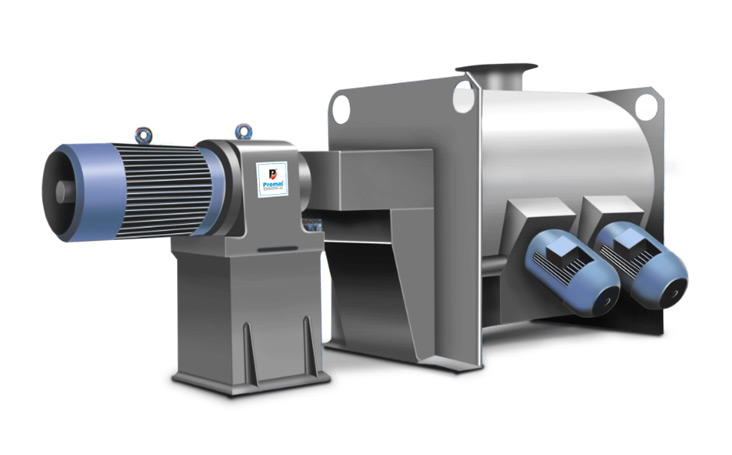

Planetary Mixers

Planetary mixers are an ideal mixer for the products of different viscosities, densities, shapes & proportions. The major uses include the production of latexes, dispersion & micro – dispersion of Chemicals, Explosive & agricultural pesticide formulations. It is suitable for mixing / blending powders as well as through mixing of ointments, creams, lotions, toothpastes, resins, slurries, ceramics, colors, pigments, rubber & other compounds.