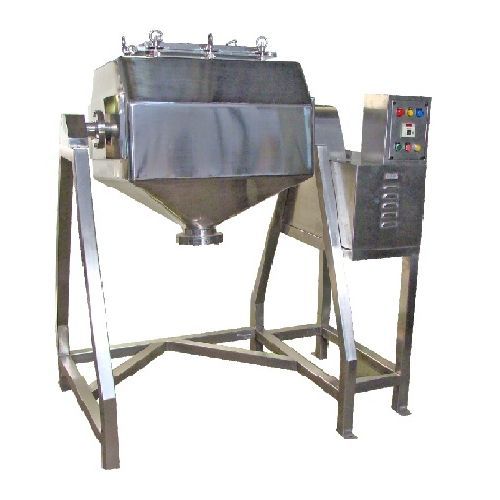

Ribbon Blender

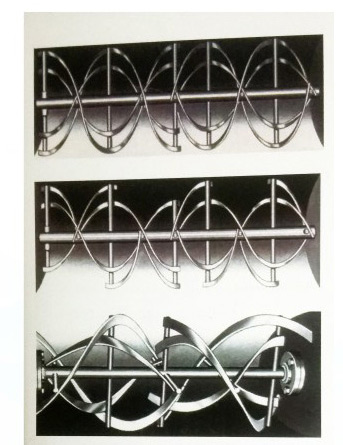

The entire unit is fabricated with engineering precision. Along with the double ribbons which provide to & fro, up & down movement to the powder 2 numbers chopper blades moving at cutting speed are provided at diagonally opposite sides to break lumps coarse particles of the mixture. Liquid spraying nozzles attached with suitable pneumatic dozing system is kept optional. This ensures small amounts of any liquid such as perfumes or fortifying agents to be sprayed and mixed thoroughly with the powder. Proper venting system is provided to prevent powder mist spreading around the working area of the mixers. We are authorized manufacturer, supplier and exporter of ribbon blenders according to ISI guidelines and user’s requirements from Mumbai to India and all over the world since 1990.