PARESH ENGINEERING COMPANY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PARESH ENGINEERING COMPANY

Sigma Mixer

Sigma Mixers (Kneader) is modern heavy duty mixer specially designed to produce uniform mixing and kneading heavier viscosity materials. It is suitable for many applications such as different kinds of doughs, stiff pastes, adhesives, polyester compounds, flush colours, brake lining compounds, resigns, soap, PVC coatings, rubber compounds, food dough, etc.

Operation

Loading of material is done through top of mixer on opening the lid or through the feeding mouth / hopper. On starting the machine, the tangential action of mixing and kneading is thoroughly obtained by ‘Z’ shaped kneading blades, which rotates very accurately at different speed towards each other causing product to be transferred from blade to blade. Discharge of the mixed product is achieved by tilting the container or through the valves at the bottom or by means of an extrusion screw below the container if provided.

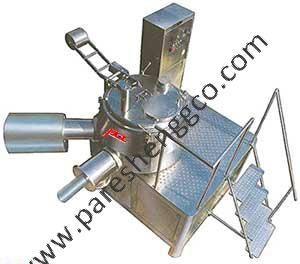

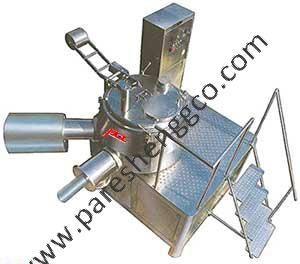

Rapid Mixer

Operation - Rapid Mixer Granulator is designed to achieve excellent mixing and consistent granules at lower operating cost along with higher productivity. Better mixing and closed control of granule size leads to faster speed with improved quality and least rejections.

OUTSTANDING SALIENT FEATURES of Rapid Mixer:

• Top of the platform is made from SS sheet. Entire stand is also cladded by SS sheet, making the machine total G.M.P.

• Chopper housing is entirely made from S.S. having air purging and special seals.

• Two stage housing for main impleller eliminating totally any chance of cross -

contamination between bearing grease and product mix.

• Rapid Mixing Granulating can be done through Mechnical seals with vaccum creating to the material.

• Five micron dust filter is fixed on the lid to eliminate dusting in granulation Area.

Plough Shear Mixer

Basic construction - plough shear mixer operates on hurling and whirling mixing principal and is the most effective system in all application for Solid solid mixing,solid liquide mixing, homogenizing, blending, granultion and drying of industrial material providing high mixing quality within short duration.

It is batch mixer having horizontal mixing system with horizontal, cylindrical drum and horizontally installed mixing main shaft which passes through both the end plates fitted with specially designed bearing housing and seals. Plough shear shovels are fitted on arm of the main shaft keeping minimum clearance between plough shaped element and shell wall. The mixer is provided with suitable valve depending upon the application and feed material. Flush bottom type gate valve or butterfly valve for discharge is provided at the bottom of the drum, which operates manually or by pneumatic system. Cleanup windows can be provided at the side of mixers with interlocking unit. In case the small quantities of liquids are to be added, spraying system with nozzle can be provided.

Mass Mixer

The Mass Mixer Machine is basically mixing assembly with paddle type mixing blades in horizontal position in the container & have a single speed, simple rotation. The blade rotates around it self at a very slow speed inside the bowl and thereby achieving intimate mixing of dry or wet materials of Tablet Granulation, Powder, Chemicals, Food & Confectionaries Materials.

Because of a special design feature of machine & blades, the mass mixer can mix the lumpy materials & also uniformally and intimately mix the materials which are difficult to mix.

SALIENT FEATURES

• All contact parts are made out of S.S.304/316/M.S quality material.

• Compact design requires comparatively smaller floor space.

• Single blade with single speed for dry & wet mixing.

• Proper sealings arrangement is provided to eliminate any black particle contamination problem, leakage, wear & tear.

• All moving parts are enclosed with safety guards.

• Easy for cleaning & operating.

• Interlocking system with top dust cover, to avoid accident, during process.

• The container tilting system provided for easy unloading of material and easy cleaning.

• Specially designed all moving parts provided with provision of easy lubrication.

•Ideal for mixing of Pharmaceutical powders, chemicals, food and confectioneries etc.

Mixtruder

Mixtruder is used for the mixing-kneading of materials with very high viscosities (over 500, 000 cps). With its unique design of Z-shaped mixing tools installed in two semi-cylinders, the PerMix PSG series Mixtruder is able to provide combined functions of compressing, stretching, folding, kneading & mixing, which makes it widely used in the chemical, food, sealing compound and paint industries, among others.

Ribbon Blender

Mixers have long been noted for their efficiency in mixing dry powders and granular materials, adding small quantities of liquids to a dry batch, and for flowing paste. Recent modification in design, and the addition of auxiliary equipment have, however, greatly increased their field of usefulness.

Ribbon Blender is suited for solids blending where the material is less than free flowing. They are available in the customary U-Shaped trough with a variety of agitator arrangements. We offer sanitary design as well as heavy-duty versions utilizing heavier walls and oversized shafts and bearings for especially dense materials.

Fast and Effective Blending : The Ribbons (Inner and outer) are so arranged that when rotated it reaches each and every corner of the trough and imparts radial and linear motion to the whole of the materials to be mixed. At the same time material is moved from side of the trough to the centre and from the centre of the trough to the sides, resulting in quick and fast homogenising of the product. Blending is achieved in semi fluidised state in the upper zone of the trough when used for fine Powders. Double Ribbon configuration also brings material towards central bottom outlet when discharging.

Double Cone Blender

The Double cone blender is used for the intimate blending and mixing of dry powders,granules and crystals like colours, pigments, minerals, dyes, flour, grain, ceramics, detergents and other food, pharmaceutical and chemical powders. It is easy to clean and is available in wide range of specifications.

SALIENT FEATURES

• The conical shape at both ends enables uniform mixing in short period and easy discharge.

• All contact parts are made out of stainless 304/316/MS quality material, as required by customer.

• Maximum care has been taken to ensure safe operation of the unit.

• Safety gaurds will be provided with interlocking system.

• Suitable size of butter fly/Irish diaphragm valve at one end of the cone provided for material discharge & other end will be provided with openable cover for material charging & cleaning.

• One shaft with fixed buffels is provided inside the cone.

• Unit will be availale in Standard/GMP and flame proof.

Octagonal Blender

OPERATION The OCTAGONAL BLENDER is an efficient and versatile blending machine for mixing and lubrication process of dry granules homogeneously. Two third of the volume of the Blender is filled to ensure proper mixing. The Octagonal Blender gives best result for granules due to very slow speed and octagon shape of container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc.

SPECIAL FEATURES

• Suitable for dry mixing of products in granule form.

• Easy for loading and unloading of material.

• Easy for cleaning.

• All contact parts are made out of SS 304 / SS 316 quality material, as per customer requirement.

• The octagonal shape & slow speed of rotating gives sufficient continuous movement to the granules, thus results in good quality.

• Simple design requires minimum maintenance.

• Maximum care has been taken to ensure safe operation of the unit.

• Manual rotating facility with hand wheel for inching.

• Bigger size batch at low power consumption.

Drum Blender

The Drum Blender system has been designed as an integral cycle system from formulation to utilisation. It involves mixing & batch identification of the product during intermediate steps inside the same hermetically sealed container. This system allows that the G.M.P. is followed as closely as possible (no cross. contamination, no pollution of the environment)

The machine consists of a fabricated MS Drum rotating at 20 RPM. It has an open able door in front, through which the SS Bins containing the products are loaded in the Drum. After the mixing, the Bins are removed and the Drum is recharged with another loaded Bin

Y Blender Or V Blender

Popularly known as "V" Blender or "Y" Blender is highly favored by the pharmaceutical and fine chemical industries, this design is superor to Ribbon Blenders and drum mixture. As the vessel rotates from the "V" position, the batch is divided into right and left legs. As the vessel continues its rotation, the batch blends and recombines. V Blenders can be built to suit customer requirements.

SPECIAL FEATURES

• Suitable for dry mixing of products in powder form.

• Easy for loading and unloading.

• Easy for cleaning.

• All contact parts are made out of SS304 / SS316 or SS316 L quality material, as per customer requirement.

• Simple design requires minimum maintenance.

• The "V" shape gives sufficient contineous movement to the granules, result in good quality.

• Shorter blending time

• Quick and complete discharge

• Lower power consumtion

• Liquid spray system and jacket are optional

Rotocon Blender

we are mainly looking for Fluid Bed Coater and Starch Processing Machinery queries.

We are recognized as leading manufacturer, supplier and exporter of a wide range of Rotocone Blenders. All the contact parts made out of stainless steel of required grade by customer. These blenders are extensively used for mixing of the different liquids in the food and chemical industry. These products are widely used to blend various types of material efficiently.

Features:

- Sturdy design

- Easy to maintain

- Rust proof

Ball Mill

Ball Mills have a wide range of applications and are especially suited to process materials where dual operations of grinding-cum-mixing is required. Ball Mills are almost indispensable to Industries manufacturing Paints, Chemicals, Lime¬Pazzolana, Cement, Inks, Pharmaceuticals, and Mineral Mixtures and other allied Industries. Ball Mills employ modified drive arrangement to reduce the Mill cost as well as for smooth trouble free operation.

SPECIAL FEATURES:

1. Cylindrical shell are with heavy duty alloy steel trunnions.

2. Counterbalance is directly opposite to man-hole opening.

3. Heavy support stand is provided.

4. Replaceable liners. (On request).

5. Easily removable cover.

Attrition Mill

Mills are designed to produce high quality, superfine grinds over a very short period of time, using a minimum of energy and a minimum of floor space.

Advantages of the Attrition Mill Process

• Fine homogenous dispersions

Average particle sizes of 1 micron or less of solid bodies in high concentrations without entrapping air.

• Shorter grinding times

Up to ten times faster than conventional equipment, such as ball or pebble mills.

• No premixing

Ingredients may be added at the beginning or any other time during the process.

Corrections can be made without stopping the machine.

• Low power consumption

Due to favorable distribution of the installed energy, all power is used for grinding and dispersion.

• Minimum floor space

Attrition Mills are extremely compact in size and re¬quire no special foundations.

• Safe operation

Good checking possibilities and the stationary grinding chamber ensure safe operating conditions.

• Low maintenance

Simplicity of design and operation means minimum maintenance and downtime

Multi Mill

MULTI MILL is a self contained portable unit useful for high speed GRANULATING, PULVERISING, MIXING, SHREDDING AND CHOPPING, etc., of a wide range of wet and dry materials without special attachments.

As compared to the four common principles of size reduction i.e. grinding, compression, impact and shearing, which often do not produce controlled size reduction, this machine utilises the principle of variable force swing hammer blades having both knife and impact edges rotating with a carefully selected screen and multiple speed option to control size reduction.

SPECIAL FEATURES

• Suitable for dry and wet granules.

• All contact parts are made out of SS304 quality material. (SS316 quality is optional )

• Wide range of SS Perforated and wire knitted screens available. Higher screen opening area for higher output.

• Multiple beaters with knife edges, impact edges & scrapper blades.

• Machine rated for continuous operation.

• Higher output with process uniformity.

• All contact parts can easily be dismantled and cleaned for change of product.

• Machine portable on castor wheels.

• Reversible direction of blade rotation.

Colloid Mill

OPERATION:

Product is fed into hopper and specially designed feeding device push the material to stator and rotor for high shearing, cutting and rubbing forces. Due to conical arrangement, the slightly deviating tapeiring of the milling surface of the stator and rotor, the angular gap becomes narrower towards the discharge section and the centrifugal effect of the rotor rotates at a high speed, the material is then forced into next tooth stage. The tooth breaks the particles with high degree of forces. Intence whirling multiples the grinding and mixing effect. The processed material continuously leave the mill through the drain pipe/discharge spout, if required it can be recirculated.

SPECIAL FEATURES

• All contact parts are made out of SS304 / SS316 / SS316 L quality material.

• Coupling provided between motor shaft and rotor for the ease in maintenance.

• 3 way valve system for draining and re-circulation of liquids or discharge spout for viscous products can be provided.

• Contact parts can be easily dismantled for cleaning.

• Flame proof construction provided if customer requires.

• Jacketed model with jacket to the hopper.

Triple Roll Mill

A Triple Roll Mill is a machine that uses the shear force created by three horizontally positioned rolls rotating at opposite directions and different speeds relative to each other to mix, refine, disperse, or homogenize viscous materials fed into it. The pasty substance is fed into the hoper, where it is drawn between the feed and center rollers.

When pre-dispersed, the substance sticks to the bottom of the center roller, which transports it into the second gap. In this gap the paste is dispersed to the desired degree of fineness. The scraper system removes the finished product from the apron roller.

The three roll mill / triple roll mill is widely used for printing ink, pigments, paints, chocolates, soap, grafite, rexin, confectioanry, cosmetics, rubber, plastics and chemical allied industries.

Planetory Mixer

Machine Description:

Planetory Mixer is a modern heavy duty mixer designed specially for uniform Mixing by planetary movement of beater(agitator). Detachable cylindrical bowl with flat / hemispherical bottom of suitable dimension and Batter / Dough Hook / Wire Whip Cage Type blade is constructed out of SS-316 / SS-304 / MS Material. Detachable agitator is bolted / fitted manually by simple twisting action.

Drive:

The Blade is driven by Single / Two / Variable Speed electric motor with suitable gearbox. Planetary disc is rotated clockwise and blade in an anti-clockwise direction on its own axis with suitable rpm. If variable speed is required, AC frequency unit will also be provided.

Stand:

The whole drive assembly is rested on MS column with heavy base frame and mixing bowl is fixed with MS fabricated bracket. The bowl with bracket is raised/down manually by handle in respect of small machines and motorized or hydraulic system is provided for lifting / lowering drive head with agitator in respect of heavy duty machines.

Special Features:

• Bowl will be jacketed for heating or cooling.

• Mixer can be designed to operate under vacuum to avoid air entrapment in product during mixing.

• The bowl will be provided with caster wheels for easy movements for cleaning, washing and handling mixed materials.

• Single blade / double blades and a Teflon edged scraper will be provided for scrapping the material from the sidewall.

• GMP / NON-GMP / FLP construction

Contradrive Agitator

|

Mighty Mixer

By combining single planetary blade with high speed disperser, Mighty mix can handle materials over an enormous range of viscosity and accomplish the work of two mixers of your process line. The planetary blade continuously sweeps the side wall and forcing material to the center of the vessel and high shear disperser Teflon side-scraper is provided for scrapping the material from side-wall. You can begin the mixing process with low viscosity, non-flowable pasty end product. Dispersion liquids ad solids, the Mighty mix can complete the mixing process faster and more thoroughly and efficiently due to high shear mixing action.

Once the mix cycle is complete lift the head hydraulically along with the blade and roll the vessel to a Discharge System work by hydraulic pressure system where the end product will be discharged to a secondary mix vessel or directly to metering /dispensing/packing equipment. The process enhances operators safety and reduces the risk of contamination and also save time and significantly reduces production cost.

Vibro Shifters

The vibro screen is circular unitized advanced gyratory screen with mechanical vibration. The motivation is through a motor with double shaft fitted at both ends with eccentric weights.

The whole drive assembly is mounted on a cylindrical base with rugged springs which allow the unit to vibrate freely and, at the same time, the spring prevent transmitted vibration reaching the floor area on which the machine stand. Screen decks are mounted one on other for multi separating.

Units are available in MS / SS 304 / SS 316(GMP/Non GMP) with multi-decks

Advantages:

- Lower power consumption

- Lower noise level

- Minimum maintenance

- Minimum space

- Superior and fast separation

Oscillating Granulator

Oscillating Granulators is used for Pharmaceutical, Chemical, Food and Fertilizer Industries.

This machine gives high output with less percentage of fines and has the salient features like Robust Simple and Compact design, Easy installation in production line, Uniform granules, Maintenance free and can be attached with Vacuum loading and discharge arrangement or Gravity flow system. The granulating chamber and internal parts are totally washable from inside. The inner surfaces are mirror polished to prevent adherence of the product and facilitate cleaning. Sliding rails and fast fixing devices allow easy mounting and dismantling of the accessories.

The oscillating motion of rotor gives uniform granules with less fines. Granule size varies as per the perforation of sieves. The simple design of Rotor and Sieve mounting facilitates easy cleaning and quick change over. Externally fitted bearing housings prevent the product coming into contact with bearing lubricants and hence the granules will be completely free of black particles.

High Or Low Speed Stirrer

We have established ourselves as a renowned manufacturer and supplier of High or Low Speed Stirrer. These equipments are widely used for mechanical analysis and other laboratory applications for stirring purposes. The high speed of these equipment make these highly demanded in the market. Having a specified speed limit at which these Stirrer rotate, these equipment provide exceptional performance. We can also provide our clients an extra bearing on the coupling sleeve for reducing the load on the motor bearing.

High Speed Disperser

High speed disperser is specially designed for high speed dispersion, dissolution and homogenization of the material having low viscosity range up to 1000 cps. This advanced dispersion technology produces extremely high quality products in less time and substantially less cost.

The machine is assembled around a center column and head including drive with dispersing blade is raised and lowered by motorized / hydraulic system. Container fixing brackets are provided self centering with locking arrangements.

For high speed dispersing top entry agitator shaft with serrated cutter blade / shear disk is provided. The blade is easily detachable. Detachable cylindrical bowl with flat / Terri-spherical bottom of suitable dimension and blade is constructed out of SS 316/SS-304/ MS material.

Tray Dryer Oven

Drying ovens are used where heating and drying are essential parts of manufacturing process in industries such as Chemicals, Dye stuff, Pharmaceutical, Food Products, Colours, etc.

Construction

Drying ovens are fabricated form strong MS angle iron frame work and MS sheets for forming double walls. Glass wool is used for insulation to minimize the loss of heat and operate the oven at maximum temperature.

Heating and Air circulation

Heating is provided by best quality electrical heaters. Drying is achieved by hot air circulation by means of fan driven by electrical motors fitted at the side of the oven. The unit is also provided with air inlet, air filter, adjustable air outlet, self locking insulated door, etc.

Fluid Bed Dryer

Method of working

The Fluid Bed Dryer facilitates quick and even drying. The required volume of air is produced by means of a statically and dynamically balanced fan. The fresh air is passed through filters which removes the traces of impurities from the outside air.

The purified air is heated by either steam/electric/Thermic Fluide. The hot air passes through the product container having diffuser plate and stainless steel sieve. Due to the hot air steam the wet product gets fluidized. The material gets surrounded by hot air and gets dried due to rapid transfer of heat. The moist air passes through the filter bag to the exhaust dust.

Used For Drying

Powders,Granulates,Tablet substance, Herbs, Tea, Salt, Kernels, Cocoa, Plastic powder, Plastic granulates, Seeds, Products of macro and micro chemistry, Animal bristles, Textile fibers etc.

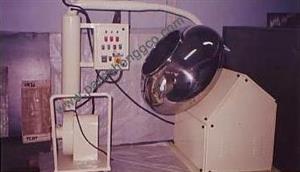

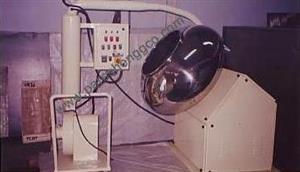

Coating Pan

Coating Pans are incorporated with the above design features and are available in various sizes. Other geometrical shapes and angles can also be provided as per requirement. RPM of Pan can be kept fixed or adjusted by a vary pitch pulley or ac frequency unit. Hot air blower is provided to feed hot air at 40° to 80°C temp, controlled by a thermostat. Quantity of hot air can also be controlled by a damper.

Polishing Pan with canvas lining available as optional with quick and easy mounting arrangement for mounting on to drive hub.

Coating Pan have very heavy & sturdy structure , made from M.S. Structural material and covered from all sides.

Coating pan made from SS304 or SS316 material and polished to the mirror finished from inside & outside.

Polishing Pan

Technical Data

Application: Polishing Pharmaceutical Tablets

Available: 36" Inch

Pan's RPM:22 R.P.M

Motor :1 H.P. III PH / 440V/AC

Pan Mounting Angle :Standard Angle 600

Nett Weight: 250 Kg

Revolving Polishing Pan is for Polishing Pharmaceutical Tablets after Sugar Coating or without Sugar Coating Tablets

Cooking Pan

|

Chewing Gum Bubble Gum Or Ball Gum Plant

|

Multi Paddle Twin Shaft Mixer

|

Cooker Cum Chikki Mixer

|

Butter Scotch Mixer

|

Caremal Roller

|

Chewing Gum Machine

|

Chocolate Tempers Machine

|

Chocolates Lab Cutter

|

Drop Roller

|

Nut Cutter

|

Nut Roster Machine

Paresh engineering company is the India's pioneer manufacturer of hot air blown nuts roasting machine. And the leading manufacturer for the category of small and cottage industry.

This machine can be used for Masala flavoring / mixing. Successfully doing chilly, pepper, honey, garlic, onion flavored roasting.

Rolling Scoring

|

Twin Screw Extruder

The advantages of twin screw extrusion

Twin screw extrusion has become the standard over time in several industries because it offers numerous advantages over single screw extrusion:

- More consistency in production and control of product quality

- Increased productivity due to continuous processing, faster start up and shut down between product changes, quick changeover and advanced automation

- Greater flexibility, with the capability to process a wide range of raw materials

- Optimized footprint thanks to energy and water savings

- Simple and easy to maintain and clean

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.