PARESH ENGINEERING COMPANY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PARESH ENGINEERING COMPANY

Ball Mill

Ball Mills have a wide range of applications and are especially suited to process materials where dual operations of grinding-cum-mixing is required. Ball Mills are almost indispensable to Industries manufacturing Paints, Chemicals, Lime¬Pazzolana, Cement, Inks, Pharmaceuticals, and Mineral Mixtures and other allied Industries. Ball Mills employ modified drive arrangement to reduce the Mill cost as well as for smooth trouble free operation.

SPECIAL FEATURES:

1. Cylindrical shell are with heavy duty alloy steel trunnions.

2. Counterbalance is directly opposite to man-hole opening.

3. Heavy support stand is provided.

4. Replaceable liners. (On request).

5. Easily removable cover.

Attrition Mill

Mills are designed to produce high quality, superfine grinds over a very short period of time, using a minimum of energy and a minimum of floor space.

Advantages of the Attrition Mill Process

• Fine homogenous dispersions

Average particle sizes of 1 micron or less of solid bodies in high concentrations without entrapping air.

• Shorter grinding times

Up to ten times faster than conventional equipment, such as ball or pebble mills.

• No premixing

Ingredients may be added at the beginning or any other time during the process.

Corrections can be made without stopping the machine.

• Low power consumption

Due to favorable distribution of the installed energy, all power is used for grinding and dispersion.

• Minimum floor space

Attrition Mills are extremely compact in size and re¬quire no special foundations.

• Safe operation

Good checking possibilities and the stationary grinding chamber ensure safe operating conditions.

• Low maintenance

Simplicity of design and operation means minimum maintenance and downtime

Multi Mill

MULTI MILL is a self contained portable unit useful for high speed GRANULATING, PULVERISING, MIXING, SHREDDING AND CHOPPING, etc., of a wide range of wet and dry materials without special attachments.

As compared to the four common principles of size reduction i.e. grinding, compression, impact and shearing, which often do not produce controlled size reduction, this machine utilises the principle of variable force swing hammer blades having both knife and impact edges rotating with a carefully selected screen and multiple speed option to control size reduction.

SPECIAL FEATURES

• Suitable for dry and wet granules.

• All contact parts are made out of SS304 quality material. (SS316 quality is optional )

• Wide range of SS Perforated and wire knitted screens available. Higher screen opening area for higher output.

• Multiple beaters with knife edges, impact edges & scrapper blades.

• Machine rated for continuous operation.

• Higher output with process uniformity.

• All contact parts can easily be dismantled and cleaned for change of product.

• Machine portable on castor wheels.

• Reversible direction of blade rotation.

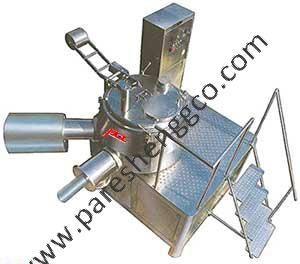

Colloid Mill

OPERATION:

Product is fed into hopper and specially designed feeding device push the material to stator and rotor for high shearing, cutting and rubbing forces. Due to conical arrangement, the slightly deviating tapeiring of the milling surface of the stator and rotor, the angular gap becomes narrower towards the discharge section and the centrifugal effect of the rotor rotates at a high speed, the material is then forced into next tooth stage. The tooth breaks the particles with high degree of forces. Intence whirling multiples the grinding and mixing effect. The processed material continuously leave the mill through the drain pipe/discharge spout, if required it can be recirculated.

SPECIAL FEATURES

• All contact parts are made out of SS304 / SS316 / SS316 L quality material.

• Coupling provided between motor shaft and rotor for the ease in maintenance.

• 3 way valve system for draining and re-circulation of liquids or discharge spout for viscous products can be provided.

• Contact parts can be easily dismantled for cleaning.

• Flame proof construction provided if customer requires.

• Jacketed model with jacket to the hopper.

Triple Roll Mill

A Triple Roll Mill is a machine that uses the shear force created by three horizontally positioned rolls rotating at opposite directions and different speeds relative to each other to mix, refine, disperse, or homogenize viscous materials fed into it. The pasty substance is fed into the hoper, where it is drawn between the feed and center rollers.

When pre-dispersed, the substance sticks to the bottom of the center roller, which transports it into the second gap. In this gap the paste is dispersed to the desired degree of fineness. The scraper system removes the finished product from the apron roller.

The three roll mill / triple roll mill is widely used for printing ink, pigments, paints, chocolates, soap, grafite, rexin, confectioanry, cosmetics, rubber, plastics and chemical allied industries.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.