PARESH ENGINEERING COMPANY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PARESH ENGINEERING COMPANY

Sigma Mixer

Sigma Mixers (Kneader) is modern heavy duty mixer specially designed to produce uniform mixing and kneading heavier viscosity materials. It is suitable for many applications such as different kinds of doughs, stiff pastes, adhesives, polyester compounds, flush colours, brake lining compounds, resigns, soap, PVC coatings, rubber compounds, food dough, etc.

Operation

Loading of material is done through top of mixer on opening the lid or through the feeding mouth / hopper. On starting the machine, the tangential action of mixing and kneading is thoroughly obtained by ‘Z’ shaped kneading blades, which rotates very accurately at different speed towards each other causing product to be transferred from blade to blade. Discharge of the mixed product is achieved by tilting the container or through the valves at the bottom or by means of an extrusion screw below the container if provided.

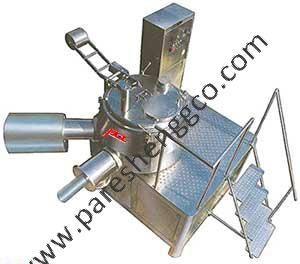

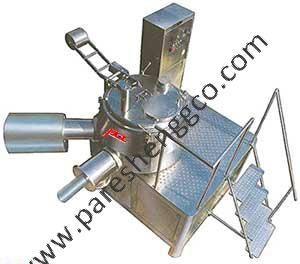

Rapid Mixer

Operation - Rapid Mixer Granulator is designed to achieve excellent mixing and consistent granules at lower operating cost along with higher productivity. Better mixing and closed control of granule size leads to faster speed with improved quality and least rejections.

OUTSTANDING SALIENT FEATURES of Rapid Mixer:

• Top of the platform is made from SS sheet. Entire stand is also cladded by SS sheet, making the machine total G.M.P.

• Chopper housing is entirely made from S.S. having air purging and special seals.

• Two stage housing for main impleller eliminating totally any chance of cross -

contamination between bearing grease and product mix.

• Rapid Mixing Granulating can be done through Mechnical seals with vaccum creating to the material.

• Five micron dust filter is fixed on the lid to eliminate dusting in granulation Area.

Plough Shear Mixer

Basic construction - plough shear mixer operates on hurling and whirling mixing principal and is the most effective system in all application for Solid solid mixing,solid liquide mixing, homogenizing, blending, granultion and drying of industrial material providing high mixing quality within short duration.

It is batch mixer having horizontal mixing system with horizontal, cylindrical drum and horizontally installed mixing main shaft which passes through both the end plates fitted with specially designed bearing housing and seals. Plough shear shovels are fitted on arm of the main shaft keeping minimum clearance between plough shaped element and shell wall. The mixer is provided with suitable valve depending upon the application and feed material. Flush bottom type gate valve or butterfly valve for discharge is provided at the bottom of the drum, which operates manually or by pneumatic system. Cleanup windows can be provided at the side of mixers with interlocking unit. In case the small quantities of liquids are to be added, spraying system with nozzle can be provided.

Mass Mixer

The Mass Mixer Machine is basically mixing assembly with paddle type mixing blades in horizontal position in the container & have a single speed, simple rotation. The blade rotates around it self at a very slow speed inside the bowl and thereby achieving intimate mixing of dry or wet materials of Tablet Granulation, Powder, Chemicals, Food & Confectionaries Materials.

Because of a special design feature of machine & blades, the mass mixer can mix the lumpy materials & also uniformally and intimately mix the materials which are difficult to mix.

SALIENT FEATURES

• All contact parts are made out of S.S.304/316/M.S quality material.

• Compact design requires comparatively smaller floor space.

• Single blade with single speed for dry & wet mixing.

• Proper sealings arrangement is provided to eliminate any black particle contamination problem, leakage, wear & tear.

• All moving parts are enclosed with safety guards.

• Easy for cleaning & operating.

• Interlocking system with top dust cover, to avoid accident, during process.

• The container tilting system provided for easy unloading of material and easy cleaning.

• Specially designed all moving parts provided with provision of easy lubrication.

•Ideal for mixing of Pharmaceutical powders, chemicals, food and confectioneries etc.

Mixtruder

Mixtruder is used for the mixing-kneading of materials with very high viscosities (over 500, 000 cps). With its unique design of Z-shaped mixing tools installed in two semi-cylinders, the PerMix PSG series Mixtruder is able to provide combined functions of compressing, stretching, folding, kneading & mixing, which makes it widely used in the chemical, food, sealing compound and paint industries, among others.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.