HMT MACHINE TOOLS LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HMT MACHINE TOOLS LTD

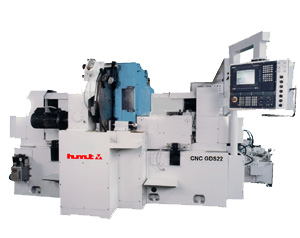

Cylindrical Cnc

Salient Features :

» Table traverse and tailstock mounted dresser.

» Angular/straight wheel head facility.

» High rapid traverse for slides.

» Turcite pasted table guideways.

» Preloaded antifriction guideways for wheel head slide.

» Work head with dead-cum-live center/work head spindle mounted on preloaded ball bushings for axial movement of the spindle through electromechanical drive (autoflagging version).

» Tailstock quill mounted preloaded ball bushings with manual taper correction.

» Moving weight type in-situ balancing equipment.

» Air blast oil cooler for wheel spindle lubrication oil.

» Automatic wheel slide retraction facility during power failure.

» 2-Axes CNC control.

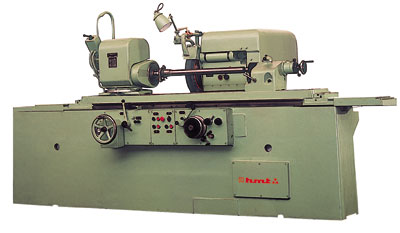

Cylindrical Non Cnc

Salient Features :

» Designed for high rates of stock removal for batch production requiring fine tolerance limits with finest surface finish.

» Available in universal and production models, having infinitely variable table traverse, with a dwell and automatic infeed at table reversals.

» The universal models are equipped with swivelling wheel head and built-in provision for internal grinding.

» A single lever controls table traverse, work rotation, coolant flow and rapid approach of wheel head during production runs.

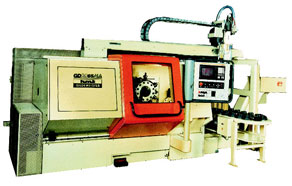

Crankshaft Cnc

Salient Features :

» High precision 5-axes Crankshaft Grinding Machine that offers economic solution for grinding of crank pins and journals of crankshafts in automatic cycle.

» Inprocess two jaw steady rest and gauge controls the finished size

» Only loading/unloading and indexing for next pin set-up to be done manually.

» Directly driven ball screws with AC servomotor for infeed axes.

» Both ends fixed and pre-stretched precision ball screws driven by AC servomotors for reliability of positions.

» Profile dressing along with end radius.

» Infinitely variable speed for work head.

» Rigid structure.

» Wheel spindle runs in special high precision tilting pad type hydrodynamic bearing with independent continuous lubrication system.

» Dual table with aerostatic lifting arrangement enable precise and easy taper setting (CSG 500 CNC).

» Counter balancing device and chucking device mounted on work spindle. Work drive motor is de-energised for balancing of crankshaft easily.

Special Executions :

» Machine with higher GWH power.

» Dynamic wheel balancing apparatus.

» Electronic automatic wheel balancer.

» Table/bed/wheel head mounted inprocess gauging.

» Constant wheel peripheral surface speed.

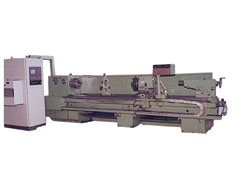

Crankshaft Non Cnc

Proven Grinder for its high rigidity, accuracy & reliability. Now with PLC control, upgraded features and various other options.

Salient Features :

» Bed made of high tensile strength cast iron, heavily ribbed for better vibration damping and shock absorption through stability and high rigidity of machine.

» Precision V & flat guideways for table with continuous automatic lubrication.

» Dual table arrangement for taper setting and taper grinding facility.

» Hydraulic stepless variable table speed with provision for dwell and dampening.

» Grinding wheel with axial movement of 5 mm on either side to an accuracy of 0.01 mm.

» Antifriction roller/turcite lined guideways for infeed slide, ensuring micronic response and repeatability.

» Both workhead and tailstock spindles are provided with eccentric clamping arrangement with chuck for adjusting according to the eccentricity of the crank pin. The required eccentricity can be set within 0-130 mm with an accuracy of 0.1 mm. Alternatively by use of gauges, the eccentricity can be set to finer limits where necessary.

» Grinding wheel spindle has a provision for axial movement of 5 mm on either side to an accuracy of 0.010 mm for shoulder grinding.

Special Executions :

» Machine with 2-Axes CNC control (Fanuc/Siemens).

» Machine with higher GWH power.

» Dynamic wheel balancing apparatus.

» Electronic automatic wheel balancer.

» Table/bed/wheel head mounted inprocess gauging.

» Simplified manual controlled machine for economical use.

Surface Cnc

Salient Features :

» Moving column type surface grinder designed for the first time in the country.

» Simultaneous 3-axes control.

» Optional creep grinding facility.

» Wide table with large clearance for job

» Bed, column, table and other structures are made out of high grade cast iron.

» Pre-loaded linear motion guideway system for Y & Z axes.

» Vertical movement of wheel head mounted on the column.

» Three linear axes. Linear scale for Y-axis.

» Digital AC servomotors for feed drives.

» Minimum programmable resolution 0.0005 mm.

» Wheel spindle runs on high precision angular contact ball bearings grease packed for life.

» Optionally retraction type dresser mounted on the table.

» Ideal for die & mould, tool room & general engineering industry.

Surface Non Cnc

Salient Features :

» Bed made of high tensile strength cast iron, heavily ribbed for better vibration damping and shock absorption.

» Precision hardened and ground antifriction roller guideways for saddle, table and vertical column.

» Higher powered wheel head.

» Automatic infeed at table reversal.

» Infinitely variable table speed.

» Ideal for components requiring an extremely accurate and highly finished flat surfaces, tool room applications. High rates of output can be obtained especially in those cases where the components can be loaded/clamped in batches on the table or on a magnetic chuck.

Rotary Surface Cnc

Salient Features :

» Designed to exploit the full potential of rotary surface grinding which has many advantages over surface grinding with a reciprocating table.

» Thickness variation near the edges of ground parts is eliminated due to the continuous contact between the wheel and the component.

» Concentric grinding finish.

» Grinding of angular shoulders around an extending hub.

» Mass production by loading small workpieces using magazines.

» Variation in work speed from the center to the periphery of the rotary table, which is a basic problem associated with rotary surface grinding is eliminated by linking the speed of the rotary table with the position of the reciprocating table.

» Rotary table rigidly fixed on table and supported on antifriction bearings.

» Table supported pre-loaded antifriction guideways.

» Large diameter rotary table with electromagnetic chuck.

» Table mounted dresser for wheel dressing.

» Diamond sizing through CNC control.

» Backlash and pitch error compensation.

» Manual pulse generator.

» Safety interlock against failure of electromagnetic chuck.

» Paper band coolant filtration system.

Universal Cnc

3-Axes CNC Universal Grinder ideally suited for external grinding, shoulder and internal grinding operations on medium/small size components.

Salient Features :

» 3-Axes CNC Universal Grinder ideally suited for external grinding, shoulder and internal grinding on medium/small size components.

» Hydrodynamic bearings for wheel spindle.

» Infinitely variable AC work head drive.

» Belt driven spindle for internal grinding.

» Tailstock and work head mounted dressers for wheel dressing.

Rotary encoder feedback for X, Z, and B axes.

» Hardened and ground guideways for X-axis with linear recirculating roller bearings.

» Turcite liners for table.

» Guideway protection by telescopic covers.

Double Disc Cnc

Salient Features :

» Ideal grinder for mass production of components having two flat and opposite parallel surfaces with higher geometrical accuracies.

» Machines up to 4-axes CNC control

» User-friendly grinding cycles by customised screen (picto programming).

» Preloaded antifriction guideways for precise positioning and rigidity.

» Super precision antifriction bearings for grinding spindles.

» Direct driven ballscrews with AC digital servomotors for linear axes.

» Hydraulic swing arm dresser.

» Automatic centralised lubrication system.

» Free-standing electrical panel and hydraulic power pack.

» Pendant type operator panel.

» Built-in safety interlocks.

» Input resolution 0.0001 mm

Special Executions :

» Variable speed drives for grinding wheels suitable for different areas on opposite surfaces.

» Machine can be equipped with rotary feeder, through feeder, rotary magnetic plate through feeder, reciprocating feeder, swivel arm feeder, oscillating feeder as per requirement.

» Diamond wheels.

» Post-process gauge.

» Wheel positioner for grinding wheel.

Thread And Worm

Salient Features :

» Seven-axes CNC Worm & Thread Grinding Machine designed for efficient and high accuracy grinding of single or multi-start worms and threads.

» Short changeover and short idle times.

» Two-axis CNC dressing attachment mounted on wheel head with the help of rotary diamond disc facilitates dressing of grinding wheel to nearly any kind of profile.

» Interpolation between C-axis and Z-axis for the generation of worm and threads eliminates the need for complex kinematics thereby reducing maintenance.

» Micro taper correction facility for tailstock.

» Centralised lubrication for guideways and ball nuts.

» Auto wheel dressing compensation.

Tool And Cutter

New modified Tool & Cutter Grinder ideal for sharpening all types of commonly used cutting tools like milling cutters, hobs, gear cutters, and tools with spiral cutting edges.

Salient Features :

» Rugged box frame structure.

» Preloaded antifriction, cartridge type spindle for wheel head to run in either sense of rotation.

» Wheel spindle can accommodate grinding wheel/interchangeable arbors on both sides.

» Tilting of wheel head in both planes for more versatility.

» Dual control of table for easy operation.

» Higher rigidity and consistent accuracies.

»

New improved wheel head on inclined plane allows use of diamond and CBN wheels and higher rated motor power, longer spindle can be used in place of arbors for better accuracies.

Ideally suited for small workshops, tool rooms, assembly section and training institutes.

Special Executions :

» Fanuc/Siemens CNC system controlled machine.

» Precision radius grinding attachment.

» DRO for all slides.

Roll Camber

Roll Camber / Cylindrical Grinder GRC 55

Versatile grinder for micro precision grinding of rolls with concave or convex cambering and heavy duty cylindrical grinding applications in general engineering industries.

Salient Features :

» Single piece robust construction with long guided sleeve for better rigidity of tailstock. Bed made of high tensile strength cast iron, heavily ribbed for better vibration damping and shock absorption.

» Dual table arrangement for taper setting and taper grinding facility.

» Antifriction roller guideways for infeed slide, ensuring micronic response and repeatability.

» Automatic infeed at table for traverse grinding operations.

» Plunge grinding cycle.

» Bearing pads of hydrodynamic super precision bearings are supported on cylindrical surfaces that adjust themselves automatically according to load changes during operations and ensure minimum clearance.

Special Executions :

» Machine with 2-Axes CNC control.

» Dynamic wheel balancing (HMT IZV-20 or MARPOSS).

» Inprocess gauging system.

» Hydraulic actuation of tailstock.

» Angular head grinding machines with single axis CNC control.

» Grinding head with wheel size f 750x150 mm & 22 kW power.

» Swing dia. Up to 630 mm.

» Table for up to 60 taper setting.

» Grinding machine for drilling rig cone (oil rigs and water borings).

» Simplified manual controlled machine for economical sue.

Grinding Center

Unique - Complete Grinding in one set-up

» Hardened and ground wheel spindle mounted on high precision antifriction bearings.

» Work head spindle supported on super precision taper roller bearings.

» 3-Axes CNC Grinder with multi-station hydraulically indexable turret for multi operation facilities - external, internal and face grinding - in single chucking with all the three wheels driven by a common motor.

» Hydraulically operated swing type auto dresser for OD, ID, and face grinding wheels by a common dresser.

» Suitable for automobile components such as gears, bearing cups, bushes and other components used in general engineering and strategic sectors.

» Ideal for flexible production.

» Significant reduction of non-productive time due to single loading/unloading cycle.

» Lower cost with faster throughput, reduced part handling and inprocess inventory.

» User-friendly grinding cycles customised screens (picto programming).

» Higher quality and shortening of cycle time due to one time clamping.

» Pre-streteched directly driven ballscrews with AC digital servomotors for linear axes.

» Auto dressing of all the wheels by a common dresser.

Special Executions :

» High Frequency internal grinding spindles.

» Hydraulic chucking devices.

» MARPOSS inprocess gauging.

» Dynamic wheel balancer.

» Air gap & crash controller.

» Linear scale for axes.

» CBN Grinding facility.

» Fully tooled up solutions.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.