TECHNIC PHARMA

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TECHNIC PHARMA

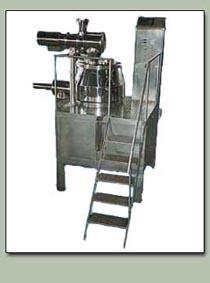

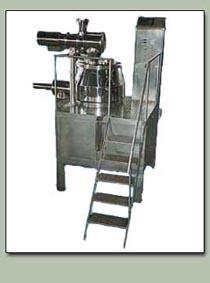

Rapid Mixer Granulator

Special Features :

1. Unit is designed to meet requirements of GMP.

2. Contact parts are either of SS 304/ 316 quality.

3. Specially designed control panels with display system and timer

4. Bowl, lid , mixing agitator, discharge housing and all other contact parts will be of stainless steel.

5. All M.S. parts of the machine are cladded/ covered with stainless steel

6. Components of the machines are having easy accessibility for cleaning.

7. All electrical and pneumatic parts are prewired to simplify installation.

8. Limit switch is provided on main lid for safe operation

9. Discharge can be provided on either side to suit clients requirement.

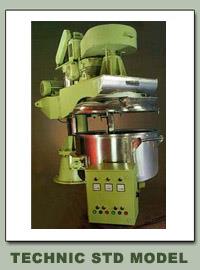

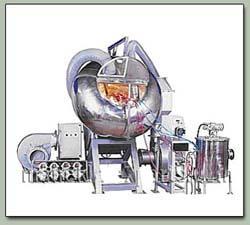

Planetary Mixer

This equipment is basically a mixing assembly where the agitation pattern is of the planetary nature The beater or the agitation assembly rotate around itself as well as travel in a circle in the bowl thereby achieving intimate mixing. Because of special design feature of shifting the mass is uniformly and intimately mixed.

The unit consists of Bowl SS Cylindrical bowl with torrispherical dished bottom with inside surface polished to smooth finish. MS Jacket on cylindrical and torrispherical area to operated on 3 Kg / cm sq. Steam pressure Complete with steam inlet and cold water inlet and outlet connections with standard fitting like pressure gauge, vent cock, release valve and drain. Bowl also suitable for vacuum application and fitted with 3 nos. Of castor wheel, two fixed and one swivel type. Suitable locking lugs for fixing bowl to the machine.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.