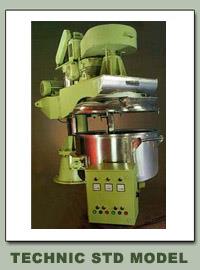

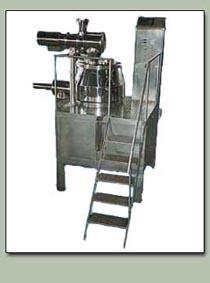

Rapid Mixer Granulator

Special Features :

1. Unit is designed to meet requirements of GMP.

2. Contact parts are either of SS 304/ 316 quality.

3. Specially designed control panels with display system and timer

4. Bowl, lid , mixing agitator, discharge housing and all other contact parts will be of stainless steel.

5. All M.S. parts of the machine are cladded/ covered with stainless steel

6. Components of the machines are having easy accessibility for cleaning.

7. All electrical and pneumatic parts are prewired to simplify installation.

8. Limit switch is provided on main lid for safe operation

9. Discharge can be provided on either side to suit clients requirement.