52563.jpg)

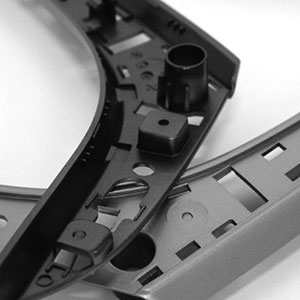

Acrylonitrile Styrene Acrylate (Asa)

Features:

ASA is an acrylate rubber modified styrene acrylonitrile copolymer

Excellent Weather Resistance

High thermal properties

Good UV Resistance

superior weatherability and design flexibility for exterior segments

High Flow

Good Impact Resistance

Good Chemical Resistance

Flame Retardant

Good Flow

Applications:

Automotive Applications (Exterior and interior parts like outside mirror, Radiator grills etc.)

Outdoor Applications

Housings

General Purpose

Electrical/Electronic Applications

Sheet

52568.jpg)

52571.jpg)

52572.jpg)

52575.jpg)

52578.jpg)

52582.jpg)

52586.jpg)

52590.jpg)

52592.jpg)

S 52602.jpg)

52607.jpg)

52622.jpg)

52624.jpg)

S 52637.jpg)

Ss 52639.jpg)