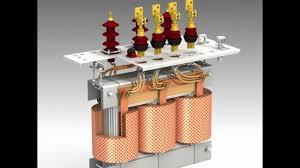

Control Transformers

APPLICATIONS :

Electrical Control Panels

PLC Power Supplies

Om Make Control Transformers are designed for good regulation, upto 100% loading. Control Transformers are widely used in industrial applications such as electrical control panels or PLC power supplies (Industrial control equipment demand a momentary overload capacity of normal capacity).

OM makes Control Transformers specification:

1. High permeable iron core.

2. High quality copper windings.

3. Class I transformers.

4. Excellent voltage regulation.

5. High short time power.

6. Vacuum impregnated varnish to ensure silent and moisture–immune operation.

7. CE marking and compatibility with EN 61558 2-2 & UL recognised components class IEIS E 318161.

8. Manufactured under ISO 9000 quality management.

PRODUCT RANGE :

Input Voltage : 110V to 600V

Output Voltage : 24V, 110V, 220V, 415,

Single Phase : 100VA to 10KVA

Three Phase : 3 KVA to 500 KVA Dry Type