NEOPLAST ENGINEERING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to NEOPLAST ENGINEERING P.LTD.

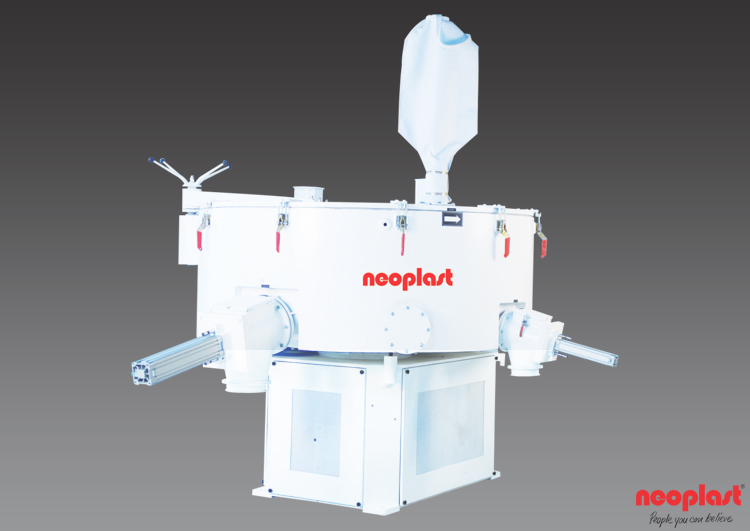

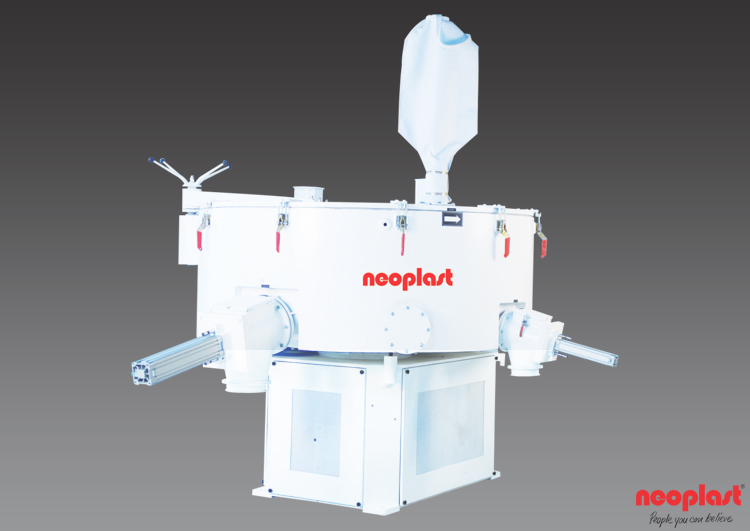

Cooler Mixer

Perfect height to dia ratio of Cooler Mixer vassel.

Precise Peripheral speed of mixing tool.

Least down time, so payback period is higher

Unmatched Pneuma seal / Capsule Technology.

Proper design of impeller.

Computerized balancing of rotating parts.

Best quality material of all key components of Cooler Mixers.

Unique design of bottom & discharge valve.

Very prompt after sales services.

Experience of manufacturing highest number of high speed mixers from the leading manufacturer and exporter in India.

High Speed Heater Cooler Mixer

- Perfect height to dia ratio of High Speed Heater Cooler Mixer vassel.

- Precise Peripheral speed of mixing tool.

- Least down time, so payback period is higher

- Unmatched Pneuma seal / Capsule Technology from the leading manufactuer and exporter.

- Proper design of impeller.

- Computerized balancing of rotating parts.

- Best quality material of all key components.

- Unique design of bottom & discharge valve.

- Very prompt after sales services.

- Experience of manufacturing highest number of high speed heater cooler mixers.

High Speed Heater Mixer

Description / Specification of High Speed Heater Mixer

We are involved in offering a wide range of High Speed Heater Mixer to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of High Speed Heater Mixer. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

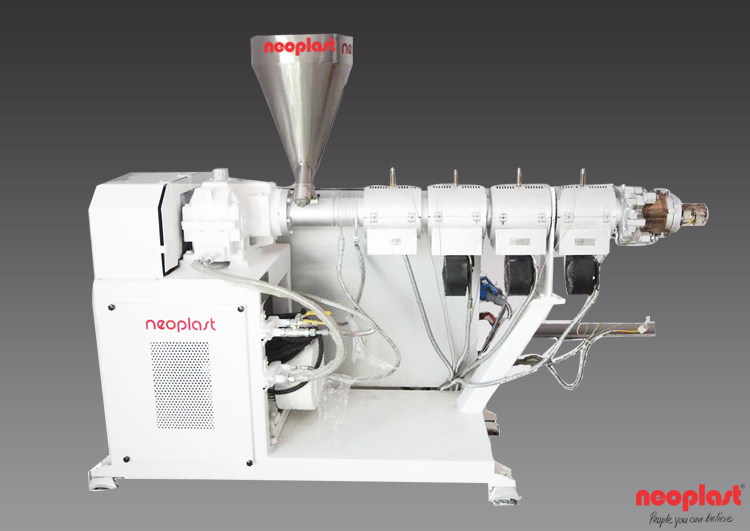

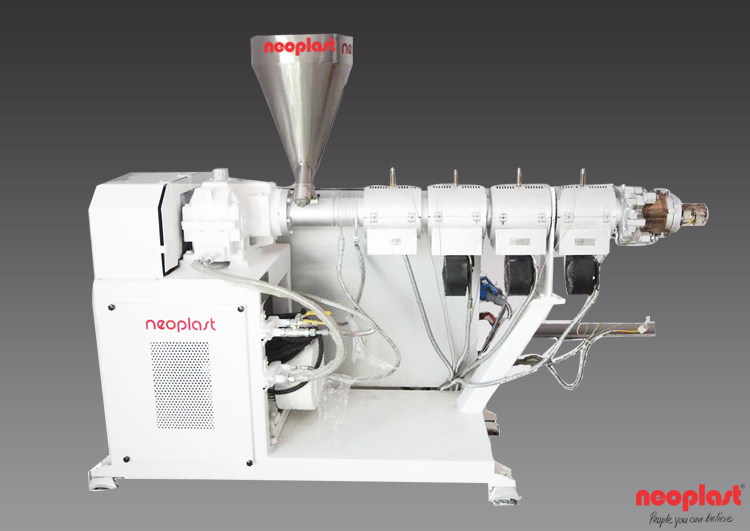

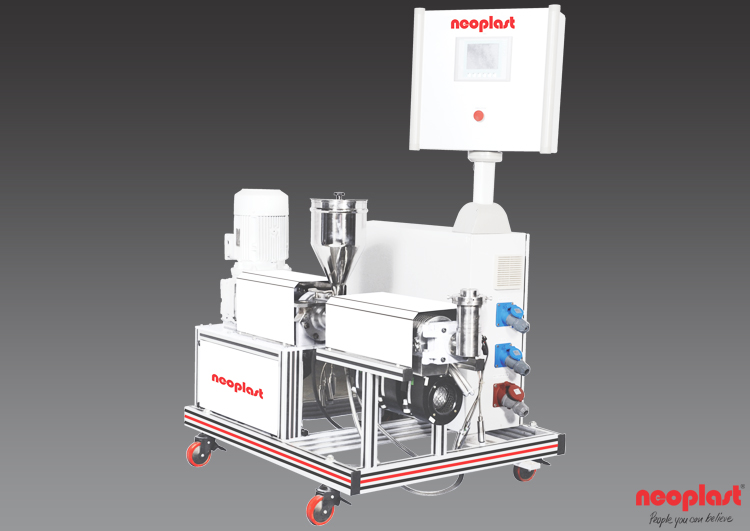

Co Rotating Twin Screw Extruder

Neoplast Make NCTE 50 (Co Rotating Twin Screw Extruder) is suitable to Filler Masterbatch Application having perfectly designed 50:1 L/D Ratio.

The rated production capacity is 400-500 *Kg./Hr depending upon recipe.

Torque limiter coupling is provided.

We are providing De Volatizing System which is having capacity of vacuum level up to 600 mm of Hg, consist of water-ring vacuum pump, vacuum vent, condenser and piping, gauges valves, sight glass and SS hood.

Standard make PLC with Push-Button Control System from the leading manufacturer and exporter of Co Rotating Twin Screw Extruder.

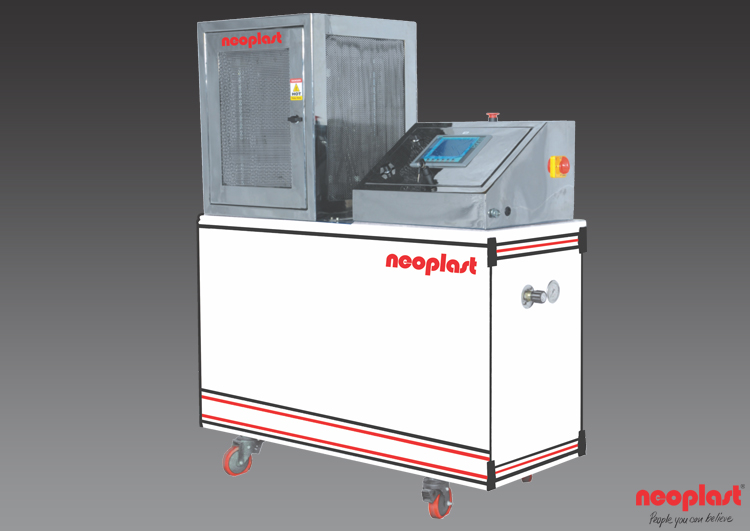

Conical Twin Screw Extruders

Neoplast has developed first time in india a fully instrumented Twin screw lab extruders with integrated data acquisition PLC. This conical twin screw extruder machine can be attached to various downstream equipment to carry out varieties of testing like extrudability of polymers, studying the problem occurring in R & D as well as in practical applications. Mamifold screws, dia heads and downstream equipment fulfill all kinds of extrusion tasks.

The sample material is plastified and extruded through dia head. All measuring values such as torque, melt pressure, melt temperature are recorded continuously and represented in the from of tables and graphs parallel to running test. Neoplast is a leading manufacturer and exporter of conical twin screw extruders with PLC in India.

Single Screw Extruder

Neoplast is a leading manufacturer & exporter of lab extruder – Single Screw Extruder and has developed a fully instrumented single screw lab extruders with integrated data acquisition PLC first time in India. Single screw lab extruder can be attached to various downstream equipment to carry out varieties of testing like extrudability of polymers, studying the problem occurring in R & D as well as in practical applications. Mamifold screws, dia heads and downstream equipment fulfill all kinds of extrusion tasks.

Underwater Pelletizing System

Underwater pelletizing system is suitable for Polymers like LDPE, XLPE, PP, TPE, Pa6, Pa66, PS, PVC, Engineering Plastics, Filled Materials etc.

Underwater Pelletizers are Designed by this renowned manufacturer and exporter in India to Produce Pellets from a wide Range of Thermoplastics and Elastomers, Partially Filled Plastics, Virgin Resins, Low Viscous Polymers, Hot Melt etc.

Moisture Content Would be as Low as 0.05 PPM or Less.

Uniform Pellets of 2mm To 3.8mm with Smooth Surface.

Fully Automatic and Close Loop System.

Thermoplastic melt is cut under the water in Semi-Molten Condition.

Simple Startup-Our System Starts just by Push of a single button.

Low Tooling Cost, Variable Tool Speed & Automatic Tool Readjustment.

Low Scrap due to Automation & Clean Operation.

Low Noise.

Air Cooled Die Face

Air Cooled Die Face is specially designed for Soft / Rigid PVC pellets.

Palletizing head mounting is specially designed to match with any single or twin screw extruders.

Palletizing head is designed with spring loaded blade adjustment which ensures uniform pellet size.

To have variable cooling time adjustable vibration is provided.

This system is easy to clean and have least noise operation.

Fines (Dust) separator is also incorporated.

Pellet cooler is compact, versatile and space saving designed on reverse air cooling principle by the leading manufacturer and exporter of Air Cooled Die Face in India.

Single Screw And Twin Screw Lab Extruder

Neoplast is a leading manufacturer & exporter of lab extruder and has developed a fully instrumented single screw lab extruder Model SSE 25 & Twin screw lab extruder Model NCMT 20 with integrated data acquisition PLC first time in India. Single screw & Twin screw lab extruder can be attached to various downstream equipment to carry out varieties of testing like extrudability of polymers, studying the problem occurring in R & D as well as in practical applications. Mamifold screws, dia heads and downstream equipment fulfill all kinds of extrusion tasks.

Two Roll Mill

Neoplast Two roll mill is equipped with attractive and user friendly control panel. Advance safety features. Torque measurement can be possible on both rolls. Trends like time < — > temp. & time < — > Amp. Can be viewed as well as printed.

Cartridge heaters for optimum even heat distribution over entire roll surface.

Roll temperature upto 300 °C. PLC controlled with HMI (Optional). Hard chrome plated, ground and mirror polished surface. Safety guards are also provided for operator during handling by manufacturer and exporter of two roll mill in Ahmedabad, India.

Drive system with geared motor and AC drive for high starting torque. Motorized nip gap adjustment device. Roll RPM can be set from 2 to 20 RPM. Rolls cooled by water cooling arrangement which is collected in a SS water cooling tank.

Hydraulic Press

Neoplast make hydraulic presses are designed to meet the diverse need of industry. NEOPLAST hydraulic press are used in many applications including R & D, Q.C. of PVC/Engineering/Rubber Compound, and Color matching etc. used for low volume production situations and quality testing in biological and mechanical fields wherever compressing is required.

Lab Mixer

Lab Mixer is a Jacketed Container of 10 Liters Vessel Capacity.

Vessel Inner and Outer Surface, lid, valve plunger are made of SS 304 and Mirror Polished.

The lab mixing tool is driven by high torque AC motor controlled by AC variable frequency drive. The tool speed can be varied from 50 RPM to 1500 RPM.

Pneumatically operated lid and discharge gate.

Specially designed bottom curvature of mixing vessel gives perfect vortex formation results into homogeneous and free flowing dry blend.

Frictional heat efficiently prepares the best quality of dry blend.

Optimum degree of dispersion is our most versatile virtue.

Quick detachable vessel can be offered for better and faster cleaning (optional).

The control panel consisting of programmable controls for optimum adaptability to the process requirements.

Lab cooler mixer with cooling cone also can be incorporated.

Neoplast is a leading manufacturer and exporter of Lab Mixer in India.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.