NEOPLAST ENGINEERING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to NEOPLAST ENGINEERING P.LTD.

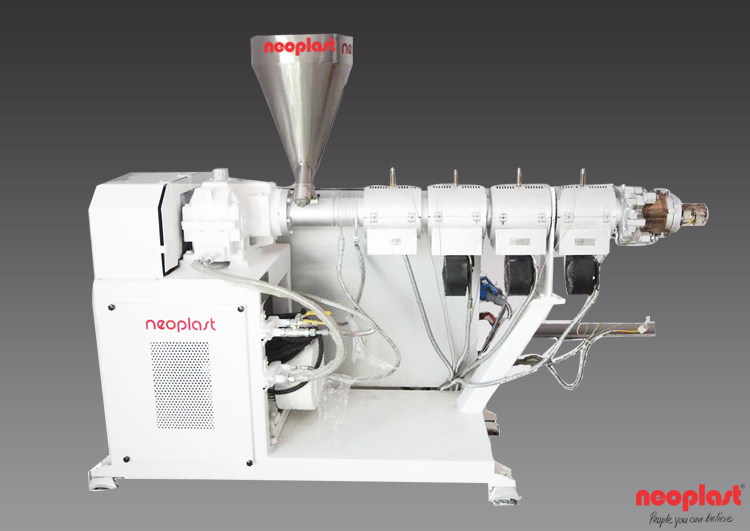

Co Rotating Twin Screw Extruder

Neoplast Make NCTE 50 (Co Rotating Twin Screw Extruder) is suitable to Filler Masterbatch Application having perfectly designed 50:1 L/D Ratio.

The rated production capacity is 400-500 *Kg./Hr depending upon recipe.

Torque limiter coupling is provided.

We are providing De Volatizing System which is having capacity of vacuum level up to 600 mm of Hg, consist of water-ring vacuum pump, vacuum vent, condenser and piping, gauges valves, sight glass and SS hood.

Standard make PLC with Push-Button Control System from the leading manufacturer and exporter of Co Rotating Twin Screw Extruder.

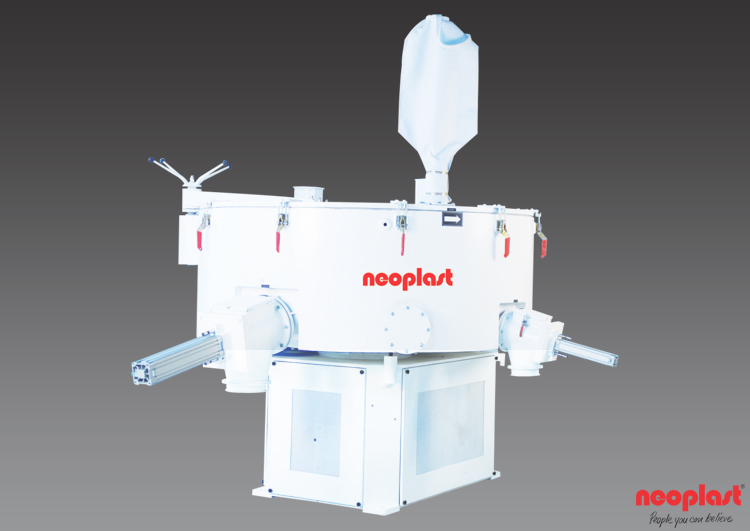

Conical Twin Screw Extruders

Neoplast has developed first time in india a fully instrumented Twin screw lab extruders with integrated data acquisition PLC. This conical twin screw extruder machine can be attached to various downstream equipment to carry out varieties of testing like extrudability of polymers, studying the problem occurring in R & D as well as in practical applications. Mamifold screws, dia heads and downstream equipment fulfill all kinds of extrusion tasks.

The sample material is plastified and extruded through dia head. All measuring values such as torque, melt pressure, melt temperature are recorded continuously and represented in the from of tables and graphs parallel to running test. Neoplast is a leading manufacturer and exporter of conical twin screw extruders with PLC in India.

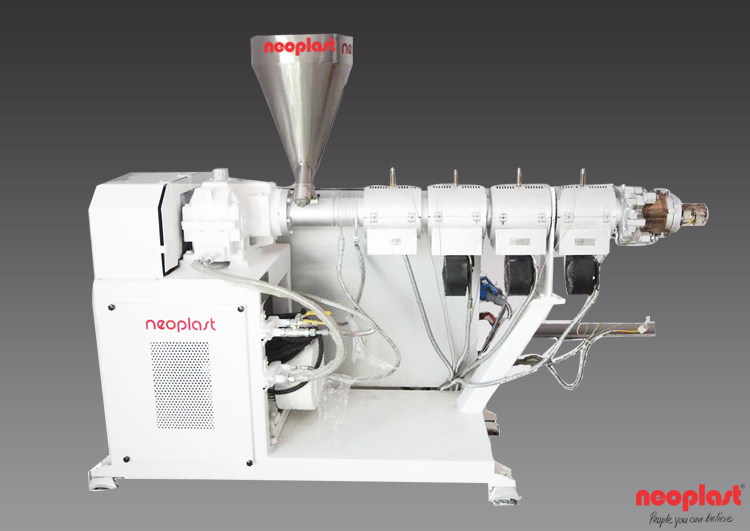

Single Screw Extruder

Neoplast is a leading manufacturer & exporter of lab extruder – Single Screw Extruder and has developed a fully instrumented single screw lab extruders with integrated data acquisition PLC first time in India. Single screw lab extruder can be attached to various downstream equipment to carry out varieties of testing like extrudability of polymers, studying the problem occurring in R & D as well as in practical applications. Mamifold screws, dia heads and downstream equipment fulfill all kinds of extrusion tasks.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.