NEOPLAST ENGINEERING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to NEOPLAST ENGINEERING P.LTD.

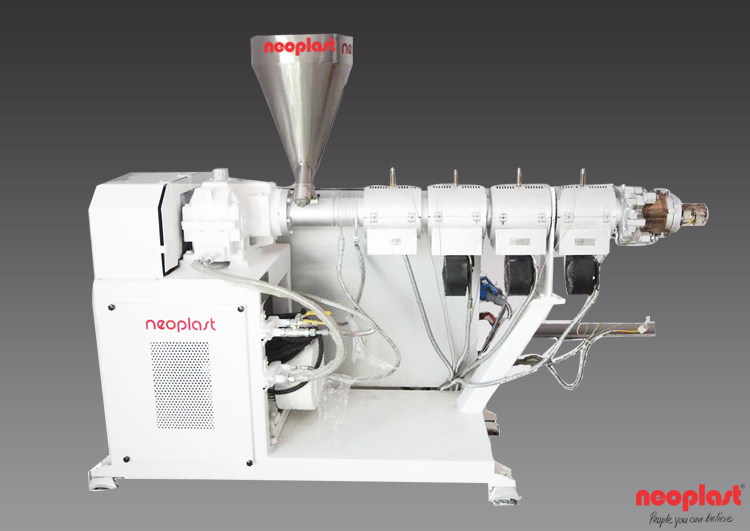

Underwater Pelletizing System

Underwater pelletizing system is suitable for Polymers like LDPE, XLPE, PP, TPE, Pa6, Pa66, PS, PVC, Engineering Plastics, Filled Materials etc.

Underwater Pelletizers are Designed by this renowned manufacturer and exporter in India to Produce Pellets from a wide Range of Thermoplastics and Elastomers, Partially Filled Plastics, Virgin Resins, Low Viscous Polymers, Hot Melt etc.

Moisture Content Would be as Low as 0.05 PPM or Less.

Uniform Pellets of 2mm To 3.8mm with Smooth Surface.

Fully Automatic and Close Loop System.

Thermoplastic melt is cut under the water in Semi-Molten Condition.

Simple Startup-Our System Starts just by Push of a single button.

Low Tooling Cost, Variable Tool Speed & Automatic Tool Readjustment.

Low Scrap due to Automation & Clean Operation.

Low Noise.

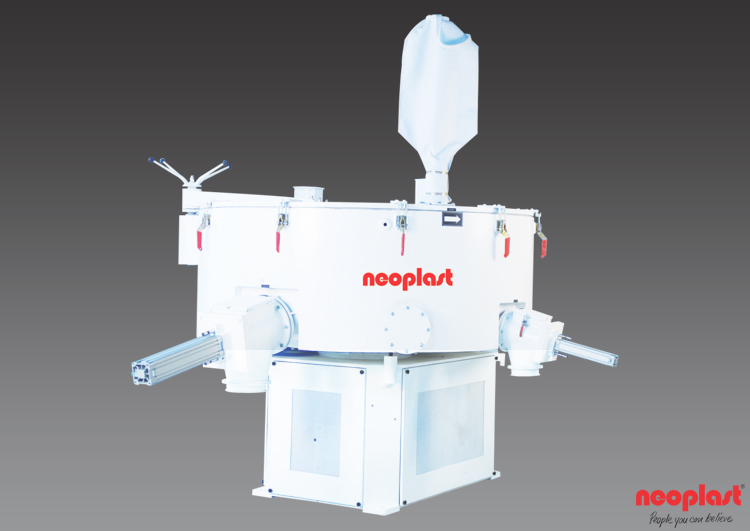

Air Cooled Die Face

Air Cooled Die Face is specially designed for Soft / Rigid PVC pellets.

Palletizing head mounting is specially designed to match with any single or twin screw extruders.

Palletizing head is designed with spring loaded blade adjustment which ensures uniform pellet size.

To have variable cooling time adjustable vibration is provided.

This system is easy to clean and have least noise operation.

Fines (Dust) separator is also incorporated.

Pellet cooler is compact, versatile and space saving designed on reverse air cooling principle by the leading manufacturer and exporter of Air Cooled Die Face in India.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.