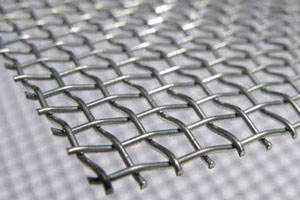

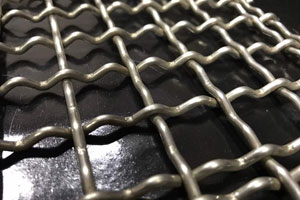

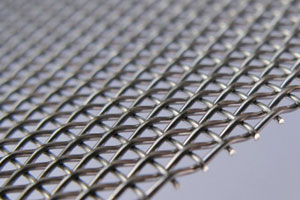

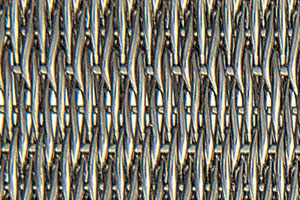

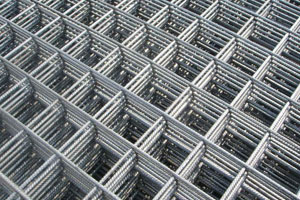

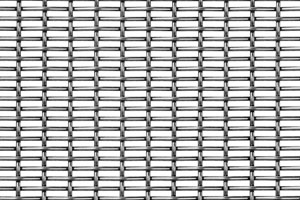

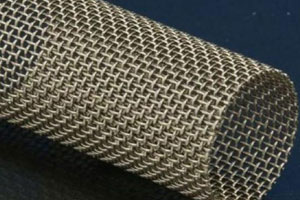

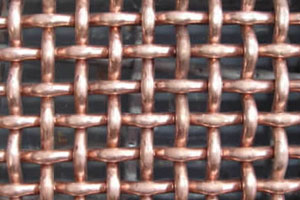

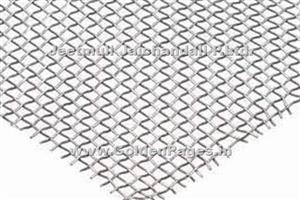

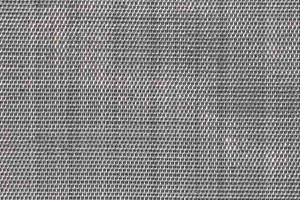

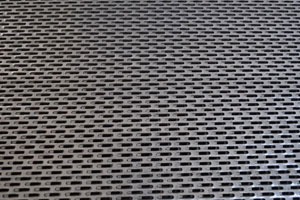

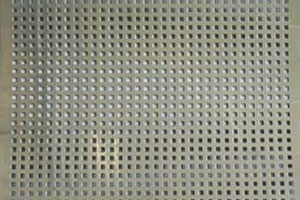

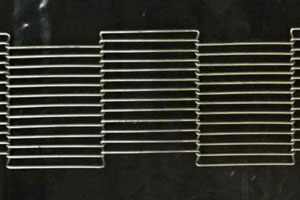

Square Wire Mesh

Wiremesh is a popular product used in the present day. Square Wire Mesh also called as wire cloth or wire fabric is an important product manufactured by Jeetmull. From industrial to commercial, this square wire mesh is put to a wide variety of application. It has a clan appearance and uniform grid patterns. This makes the square wire mesh an economically viable product. This wire mesh is used as storage containers, safety barriers, security fencing, for loading animals and more. They are also capable to be used in the construction and engineering industries.