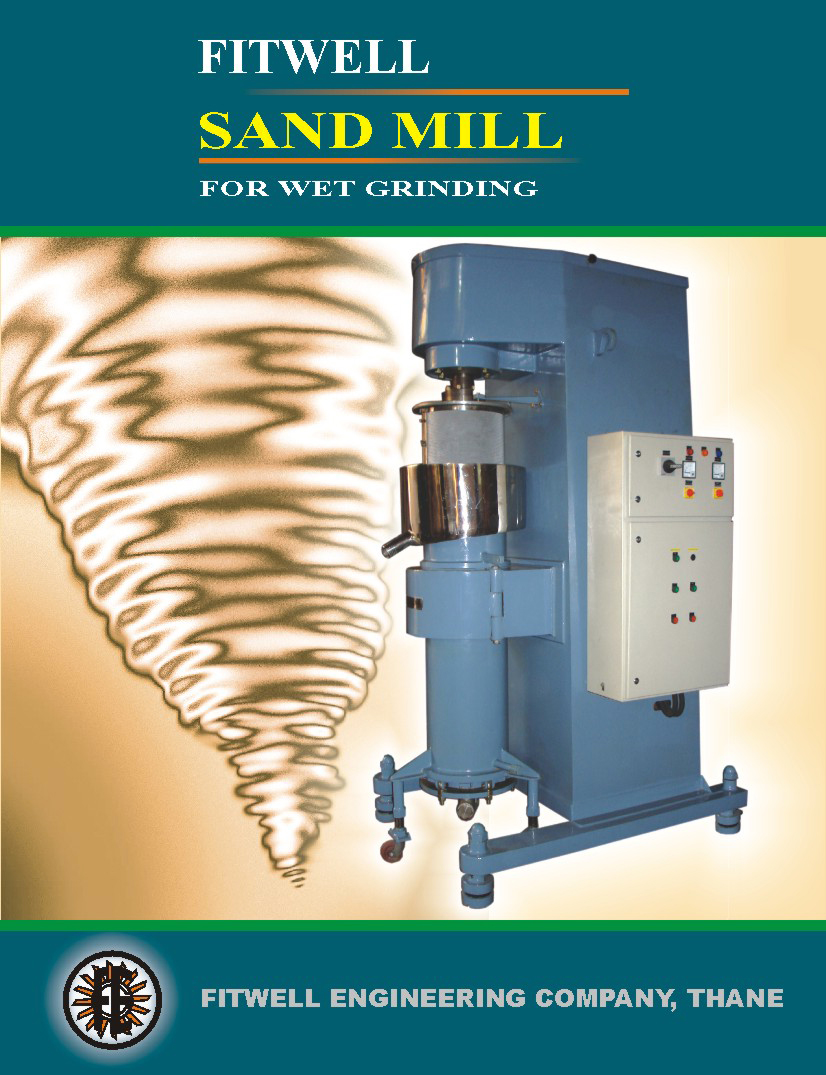

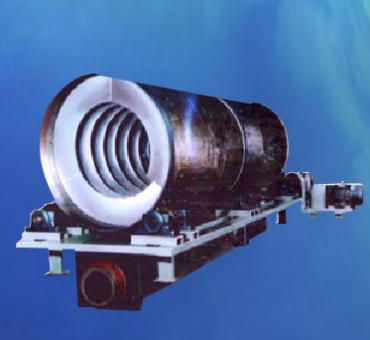

Sand Mill

Sand Mill helps in grinding the coarse materials most effectively. Partcle size can be brought down to 1 micron. The grinding material along with the filling/carrier agent is pumped through the grinding shell which consists of grinding media (grinding media can be glass beads, aluminium oxide beads or ceramic balls). With the help of high speed rotation of the rotating assembly, the grinding material is subjected to an intensive friction, shearing effect & pressure. The adjustable pump capacity determines the duration in the grinding shell. The ground materialflows out continuously & the grinding media is retained by means of special retainer sieve

49790.jpg)