Bottle Filling Machines

Features

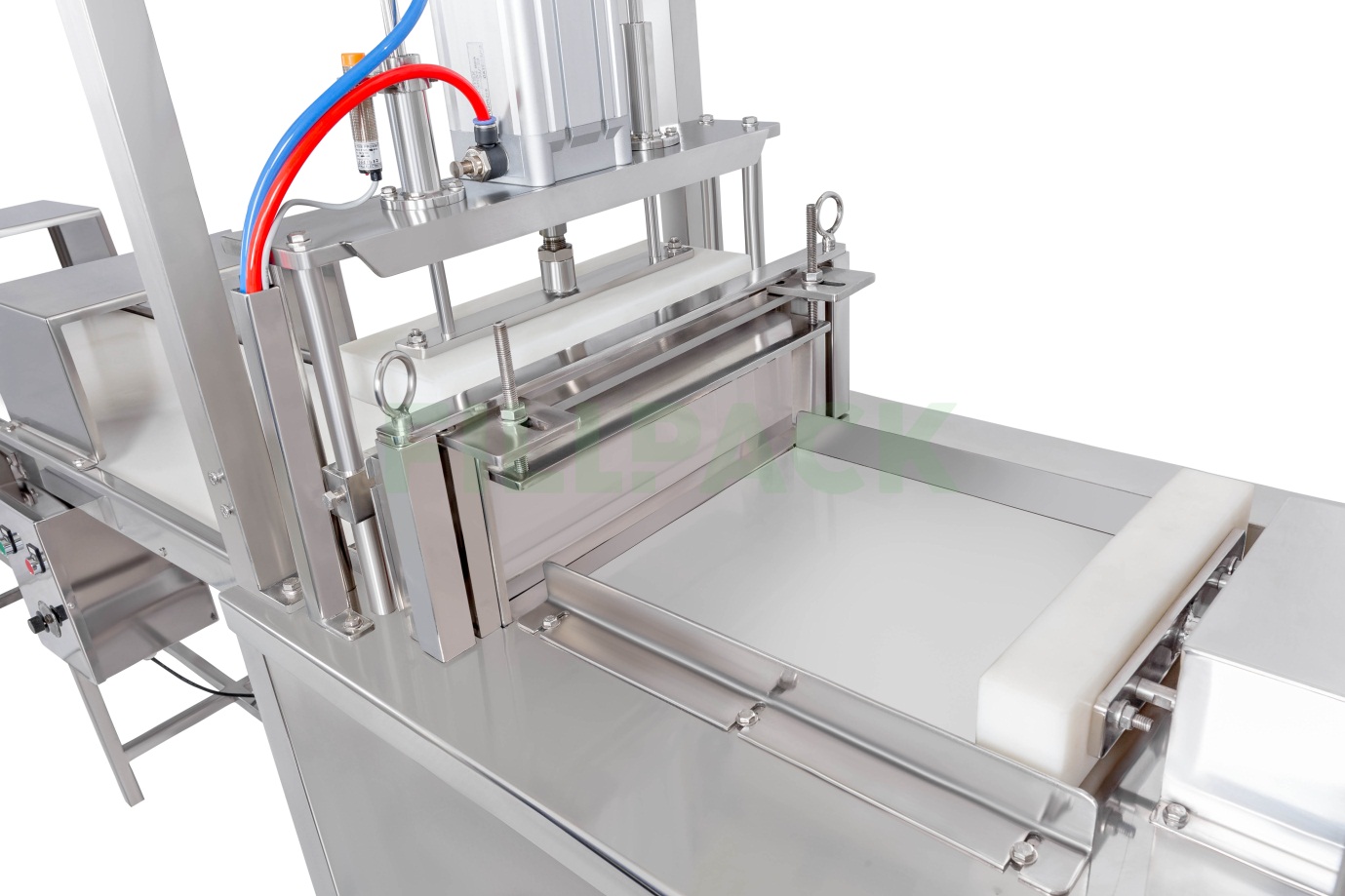

- The filling machine will be operated automatic type with 2/4/6/8 heads preferably with diving nozzle type to avoid foaming during filling process.

- All the working parts of the machine coming in contact with the product are S.S.316 (filling cylinder & nozzle).

- Conveyor had inlet & outlet ends of the machine variable speed to synchronize with the filling the filling machine speed. The conveyor tailing width adjustable.

- Casing of the machine of S.S.304

- Filling accuracy for various volumes within range of +-0.5% on volume

- Filling head height will be adjustable.

- Main motor 1 HP (Siemens, Hindustan, Bharat Bijlee).

- Conveyor Motor ½ HP. (Siemens, Hindustan, Bharat Bijlee).