ELL ESS ENGINEERING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELL ESS ENGINEERING P.LTD.

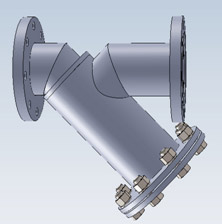

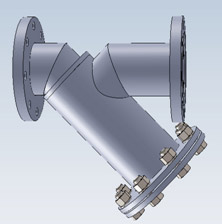

V Y Strainer

As a screen media Ell Ess Engineering uses RIPBACTM Screen where the flow is from in to out. The screen gives superior operational results & reduces the maintenance as compared to the Conventional Y Strainer. The back washing of the Strainer is done in position without opening the unit within few seconds. Due to the rigid RIPBACTM Screen the life span of the element is enhanced which reduces the operating cost

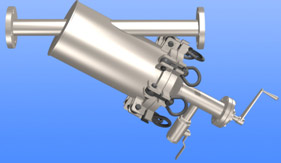

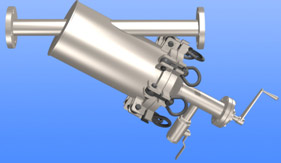

Rotary Y Strainer

Our Rotary Clean ‘Y’ Strainer/Filter with inbuilt CIP cleaning mechanism along with RIPBACTM Screen media takes the usage of this strainer to the next level. This can be fitted on pipe lines, which are running at a higher elevation from the ground level, with ease & operation & cleaning of this filter is very easy due to its CIP mechanism. This filter can be given in two versions namely :

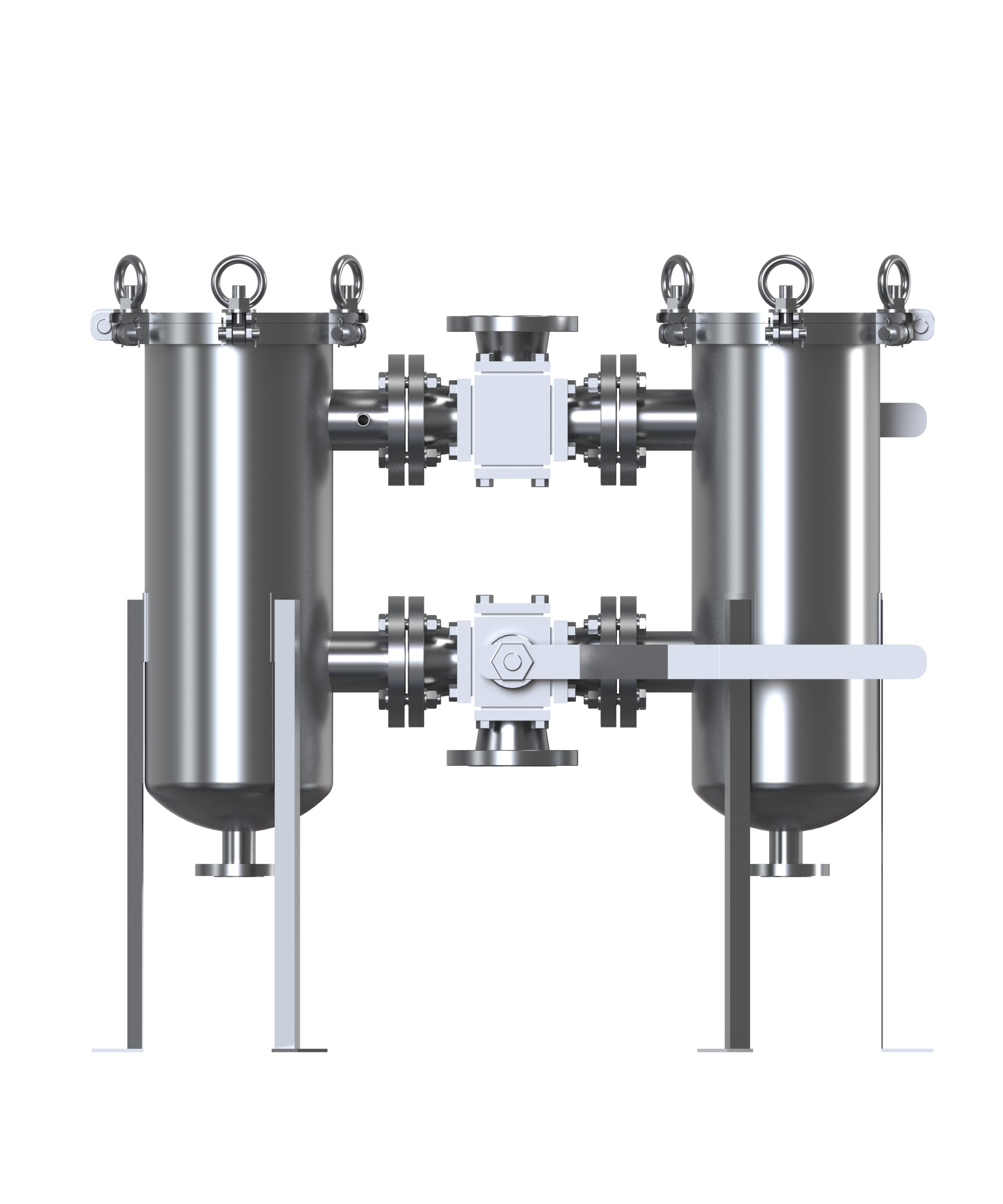

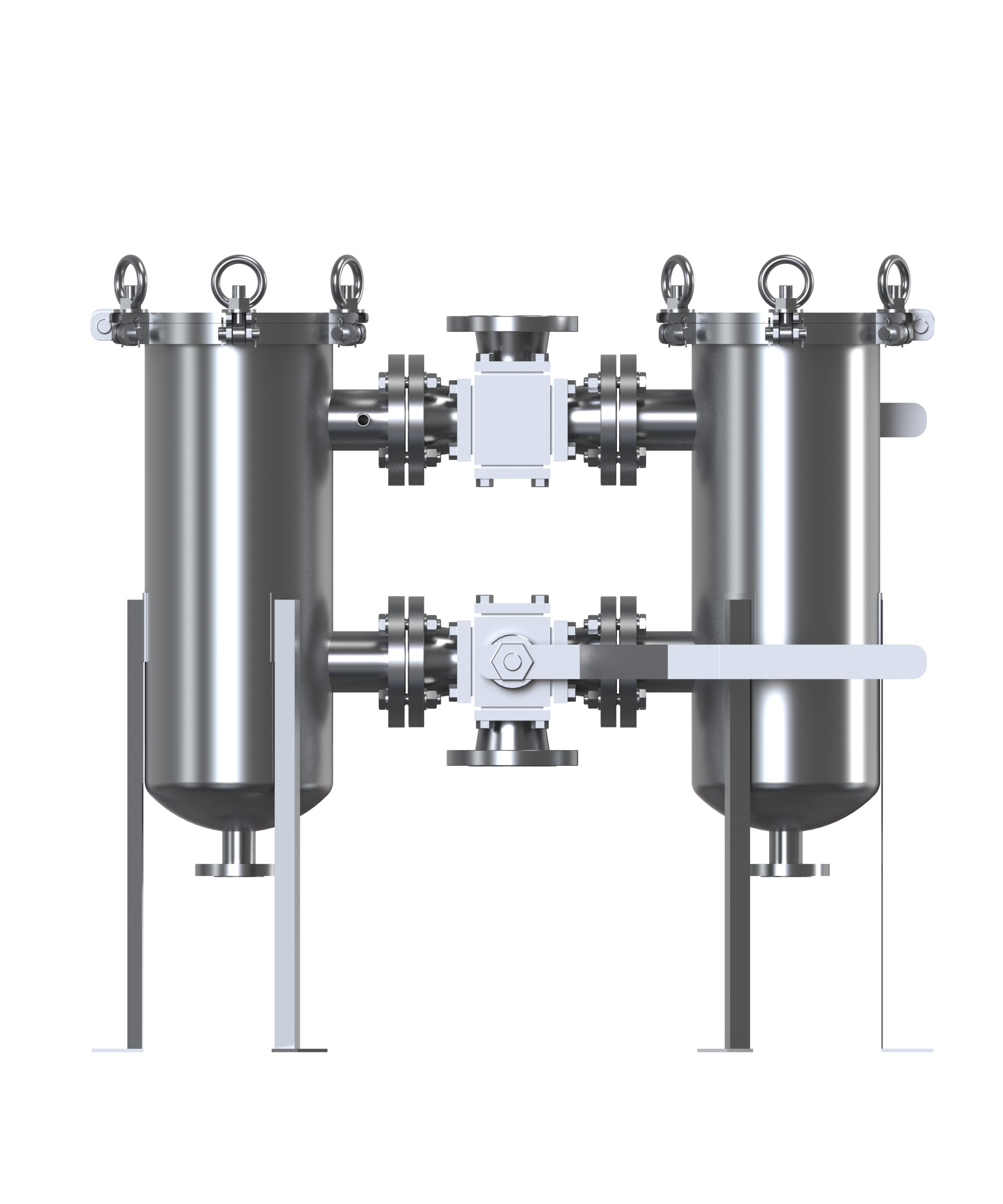

Multi Candle Strainer

For the candles Ell Ess Engineering uses RIPBACTM Screen in the Multi Candle Strainer/Filter where the flow is from out to in. The candle gives very efficient operation & reduces the maintenance as compared to Conventional Basket Strainer. The back washing is done in position without opening the filter unit within few seconds by air back wash and the slurry is flushed out of the unit. This reduces the downtime, spillage of products on the surrounding area which requires cleaning. The maintenance & man power requirement is greatly reduced. Due to rigid construction of the RIPBACTM Screen the life span of the candles are enhanced

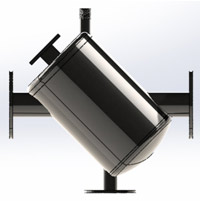

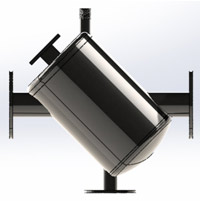

Plate Strainer

As a screen media Ell Ess Engineering uses RIPBACTMScreen. This type of Strainers are suitable for filtration of higher micron suspended solids. Especially for higher flow rates where the Basket Strainer will be huge in size the Ell Ess Plate Strainers with its compact size & insitu cleaning helps the end user. With this design of completely sealed unit, due to the positioning of the flat screen, majority of the suspended particles collects near the bottom drain point during operation. The Strainers can be back washed in position within few seconds without opening the filter and the slurry can be discharged.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.