ELL ESS ENGINEERING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELL ESS ENGINEERING P.LTD.

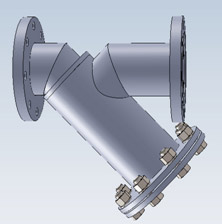

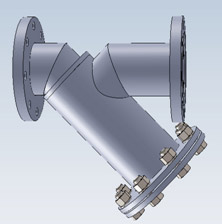

V Y Strainer

As a screen media Ell Ess Engineering uses RIPBACTM Screen where the flow is from in to out. The screen gives superior operational results & reduces the maintenance as compared to the Conventional Y Strainer. The back washing of the Strainer is done in position without opening the unit within few seconds. Due to the rigid RIPBACTM Screen the life span of the element is enhanced which reduces the operating cost

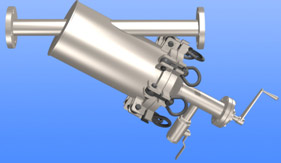

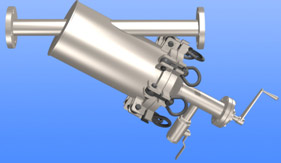

Rotary Y Strainer

Our Rotary Clean ‘Y’ Strainer/Filter with inbuilt CIP cleaning mechanism along with RIPBACTM Screen media takes the usage of this strainer to the next level. This can be fitted on pipe lines, which are running at a higher elevation from the ground level, with ease & operation & cleaning of this filter is very easy due to its CIP mechanism. This filter can be given in two versions namely :

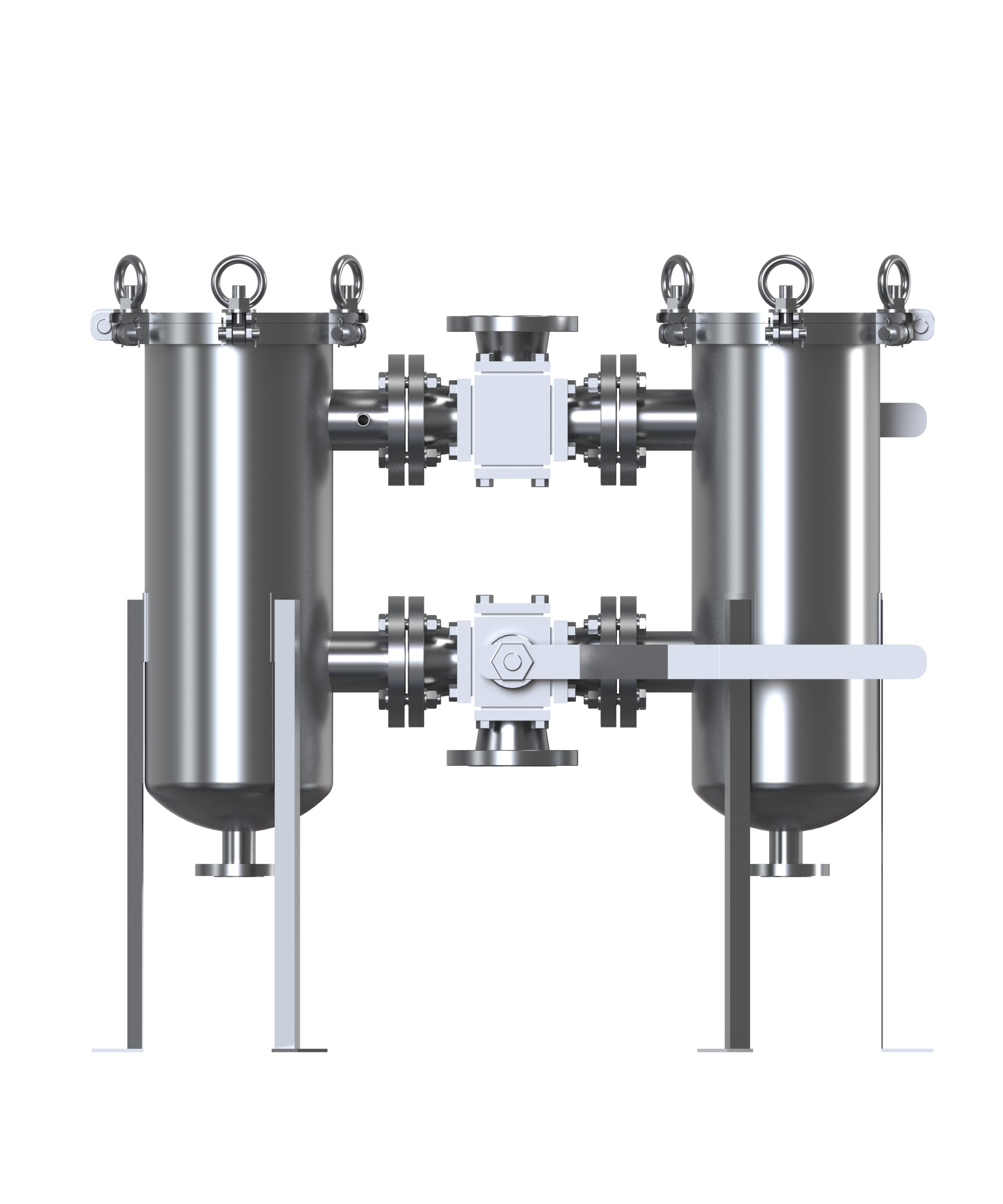

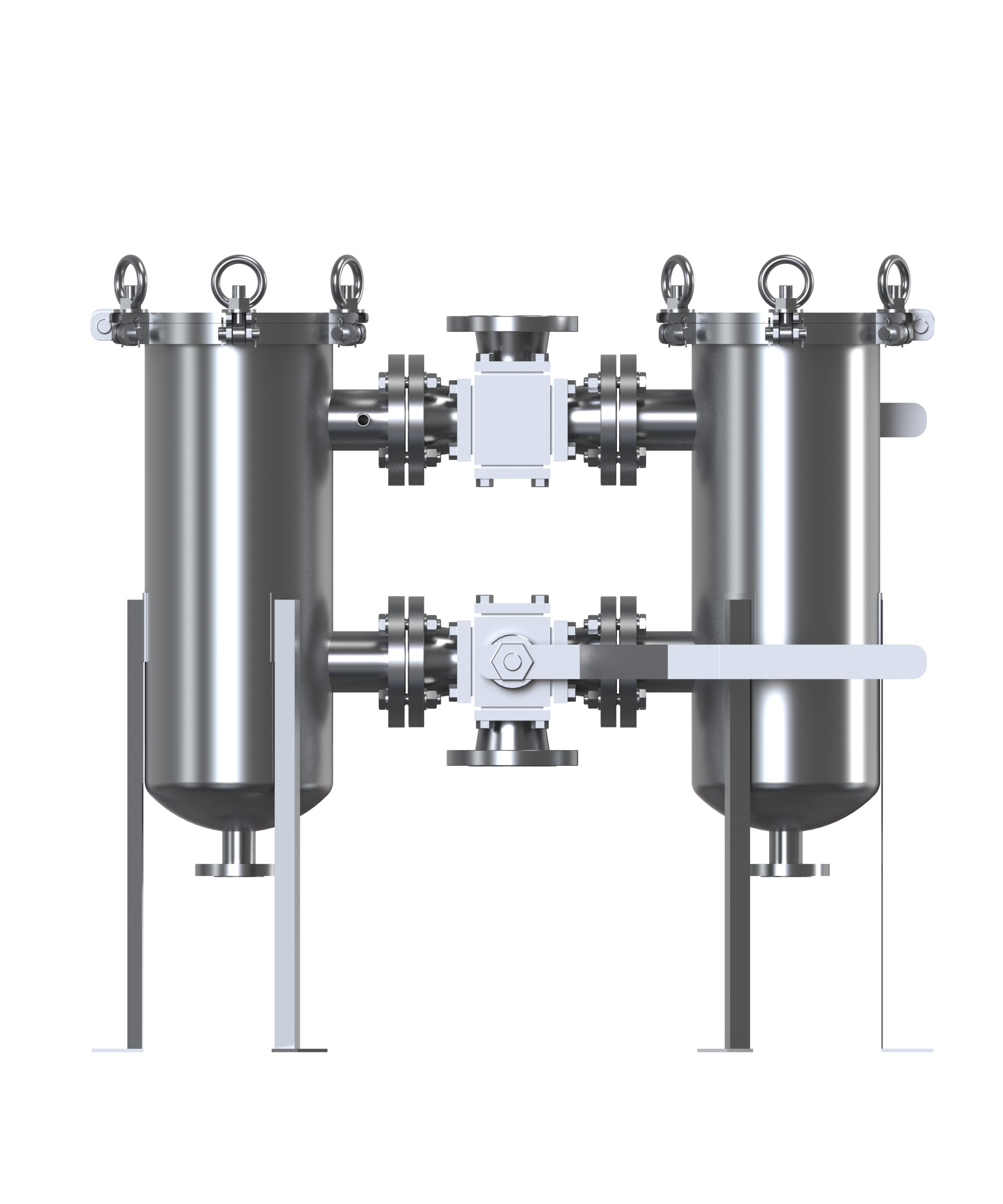

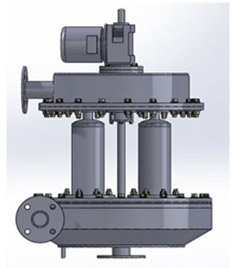

Multi Candle Strainer

For the candles Ell Ess Engineering uses RIPBACTM Screen in the Multi Candle Strainer/Filter where the flow is from out to in. The candle gives very efficient operation & reduces the maintenance as compared to Conventional Basket Strainer. The back washing is done in position without opening the filter unit within few seconds by air back wash and the slurry is flushed out of the unit. This reduces the downtime, spillage of products on the surrounding area which requires cleaning. The maintenance & man power requirement is greatly reduced. Due to rigid construction of the RIPBACTM Screen the life span of the candles are enhanced

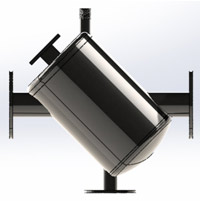

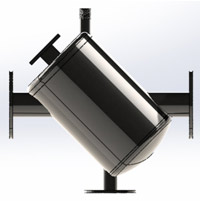

Plate Strainer

As a screen media Ell Ess Engineering uses RIPBACTMScreen. This type of Strainers are suitable for filtration of higher micron suspended solids. Especially for higher flow rates where the Basket Strainer will be huge in size the Ell Ess Plate Strainers with its compact size & insitu cleaning helps the end user. With this design of completely sealed unit, due to the positioning of the flat screen, majority of the suspended particles collects near the bottom drain point during operation. The Strainers can be back washed in position within few seconds without opening the filter and the slurry can be discharged.

Piston Filter

The liquid enters from the bottom inlet and flows through the filter element from in to out. During filtration operation the solids are deposited on the inside surface of the filter media which slowly increases the differential pressure between inlet & outlet.

When the desired ΔP set in the PLC system is reached the automatic cleaning cycle starts functioning. During the cleaning cycle the drain valve opens & the piston movement is actuated.

Due to the local pressure drop generated during this procedure the contamination will be sucked off aggravated by the backflow of the filtrate in the opposite direction. The cleaning operation is very fast. It uses the filtrate for cleaning purpose. The frequency of the cleaning procedure depends on the contamination level of the inlet liquid. The filter is user friendly, compact & is very low maintenance.

Brush Filter

The liquid enters the top inlet nozzle and the flow & the filtration takes place from in to out. During filtration operation the solids are deposited on the inside surface of the filter media. Since the brush is continuously rotating, which prevents the solids from clogging the filtration area, the regeneration of the filtration area is continuous. During filtration operation due to continuous cleaning the concentration of solids in the liquid inside the media increases, continuously it will increase the differential pressure between inlet and outlet. When the desired ∆p set in the PLC system is reached, the bottom butterfly valve opens to discharge the concentrated slurry till the ∆p comes back to the original level. The discharge operation is very fast and its frequency depends upon the percentage of solid load in the inlet.

Micro Filter

Micro Filter is a prefilter with reliable & consistent results. The filter uses multiple numbers of RIPBACTM Screen with a common scraper. With the help of the drive all the filter media will be in continuous rotation which means that the filter media are continuously cleaned to keep the filtration area always clean. As a result the unfiltered liquid concentration slowly increases during the operation inside the filter. This increases the ΔP and at a set ΔP the drain valve opens & discharges the concentrated unfiltered liquid from inside the filter. This cleaning is done during the filtration operation without disturbing the filtration flow. Due to the continuous cleaning of the filter media the filter is suitable for working under very low operating pressure which gives the best filtration results.

Desal Filter

Presently, in certain applications, three stage of filtration are employed for reducing the feed to 5 micron before feeding into membrane filter. This occupies huge amount of space requiring number of valves, fittings & instruments. Ell Ess Engineering brings to the market for the first time two stage Desal automatic Filter as a single unit, thus covering the three stages in two units. They use advanced RIPBACTM Screen media in both the stages to give the various advantages as stated earlier. As a result the filter occupies very less foot print & due to the unique design the back wash efficiency is quite high to regain the filtration area for giving trouble free operation.

Paste Filter

For highly viscous or pasty material removal of solid particles becomes more difficult and needs more force. Auto Self Cleaning Filter-Scraper, using the RIPBACTM Screen, is ideally suited for this as solids are removed by scrapping. Besides removing the solids the filter can also ensure uniform mixing of feed slurry inside the filter. It is designed to avoid frequent opening of body during process running to provide an uninterrupted flow. It is also known as Viscous or Paste filter. It is an ideal choice to handle shear sensitive liquid/pastes as well as Oil application.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.