D.V.POLYMERS INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to D.V.POLYMERS INDIA P.LTD.

P. T. F. E. Lined Hose Pipes

A Hose is a hollow tube designed to carry fluids from one place to another. Hoses are generally very flexible. The common factor in choosing hoses is size, pressure rating, weight, length and chemical capability. SS/PTFE lined corrugated hose pipe are used in petrochemical, chemical, food and pharmaceutical industry. In adding, it also finds its application in bulk transfer of lubricants, oil, paints, food products and dissimilar types of chemicals

Smooth inner core of extruded Teflon covered with stainless steel wire braid reinforcement Hose Pipes ranges from the size of 25NB to 150NB. The product has an outer body as specified by ASTM A 395 Gr. 60-40-18 and also PTFE Lined Braided Hose Pipes, Cam and Groove Fittings, Hose Clamps, Adapters Hose bellows will be supplied.

H. D. P. E. Lined Concentric And Eccentric Reducers

A Reducer is a generalized term in pipe line; It decreases or reduces the pipe size from larger to smaller bore.

The PFA/FEP/PVDF/PP/HDPE lined Concentric/Eccentric Reducers ranges from the size of 25NB to 350NB. As standard we provide both side fixed flange.

Our standard Lined Reducers are manufactured to According to the ASTM F-1545 standard dimensions We can also offer Reducers to DIN, JIS, BS ...etc. dimensions. The product has an outer body as specified by ASTM A 395 Gr 60-40-18.

The Body of Reducers with Fabricated with MS Seamless Tube / Ductile Iron/stainless steel body for various process environments. For Fabricated Reducers we can provide loose flange on one or both sides on request.

DuPont Raw Materials PFA/FEP is used to manufacture PFA/FEP Lined Concentric / Eccentric Reducers by using Transfer Moulding method at our own facility. Our Products are high strength, excellent Finish and longer life.

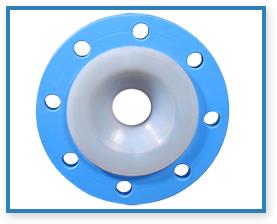

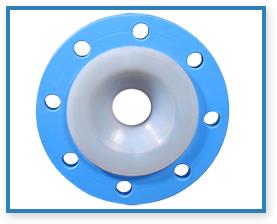

H. D. P. E. Lined Reducing Flange

The PFA/FEP/PVDF/PP/HDPE lined Reducing Flange ranges from the size of 25NB to 350NB. The Body of Reducing flange with Ductile Iron/stainless steel body for various process environments.

We Offered array of lined reducers is designed in line with the According to the ASTM F-1545 standard dimensions. We can also offer Reducing flange to DIN, JIS, BS ...etc. dimensions.

Our standard Lined Reducers/Reducing flange insures free flow of fluids for horizontal and vertical lines equally. Offered array is widely used in varied industrial applications for its attributes such as excellent performance, precise dimensions, high material strength, corrosion resistance and longer service life.

Lined Blind Flanges

PFA/FEP/PVDF/PP/HDPE Lined Blind Flange are available range from 25NB to 350NB.

A popular category of pipe flange is the blind flange. A Lined blind flange is used to close ends of Lined piping systems. It is used to provide positive closer on the ends of Lined pipes, valves, equipment nozzles. This flange helps in easy access to a line once it has been sealed.

Sight Glass And View Glass

Sight glass is a device used between any kinds of non transparent pipeline to observe the flow of liquid. This can be used both in horizontal as well as vertical pipeline. Sight glass is constructed in such a way that it gives a complete view from every angle.

We provide Tubular Sight flow indicator and FEP/PFA lined sight flow indicator.

Tubular Sight flow indicators are having parts, PTFE bushes on both sides of glass pipe section ensure that liquid in the pipeline does not come in contact with metal frame. PTFE washers are used as gaskets while fitting the sight glass in the pipeline. Acrylic cover covers the glass pipe section and protects it from outer damages.

FEP/PFA lined sight flow indicators have been designed for visually observing the flow of corrosive media. Except for the borosilicate glass, all wetted parts of the indicators are lined with FEP/PFA. These units are therefore ideal for viewing such corrosive fluids as acids, chlorides, sulphate, bleach solutions, solvents and phenols.

Sight glass can be supplied with MS/SS304/SS316 frame with any standard drilling.

P. T. F. E. Lined Dip Pipes And Spargers

Dip pipes are used to deliver or withdraw liquids or gases to and from Reactor Vessels, Columns And Storage tanks. These dip pipes can be supplied in curved units and in single & double flanged units.

PTFE Lined Dip pipe in the Range of 25 NB to 200NB, The liner thickness of the product ranges from 3mm to 7 MM The maximum length is 3000mm.

Fluoro Polymer Lined Valves

All the Valves manufactured by DV Polymers is built according to the customer needs by using most grades of carbons and stainless steels, ductile irons and other alloys in accordance with ASTM, DIN Standards. The material manufactured can be lined with PFA, FEP and PTFE. The Ball valve manufactured ranges from the size of 25NB to 150NB

P. F. A. And F. E. P. Lined Plug Valves

The plug valve has a ductile iron body with a PFA/FEP fluoropolymer liner to all wetted parts. The plug is also encapsulated in PFA/FEP providing maximum corrosion resistance. The seal is assured both up and down stream independent of the line pressure. Sizes available 25 NB to 150 NB.

P. F. A. And F. E. P. Lined Butterfly Valves

All the Valves manufactured by DV Polymers is built according to the customer needs by using most grades of carbons and stainless steels, ductile irons and other alloys in accordance with ASTM, DIN or BS Standards. The material manufactured can be lined with PFA, FEP, PTFE or ETFE.

The Valves manufactures is in the range of 50 NB to 600 NB size and can perform all the special operations like limit switch, air filter regulation, positioner and stem extension.

P. F. A. And F. E. P. Lined Diaphragm Valves

Diaphragm Valve are engineered to the top tough work environment of the chemical processing, pharmaceuticals, corrosive industries etc. We have special design bonnet which separates working valve parts from abrasive fluid and gases so that the process media only come in contact with the body, lining and diaphragm. Available from 25 NB to 150NB

E. T. F. E. Tefzel Coatings

We are identified as one of the leading brands in manufacturing and supplying of ETFE Tefzel coatings. Customers recognize us as the renowned suppliers of ETFE. In order to sustain the quality of the products we ensure the raw materials required to manufacture the product is brought from the trusted vendors in the market well known in the market for quality and trust. Also advanced machineries and techniques is used to manufacture these ETFE products in order to meet the customer expectations in terms of quality. Further is strictly tested on various quality parameters by our quality experts in order to meet the defined quality standards. Also we ensure that all our ETFE products is according to international quality standards. In order to meet the needs and requirements of the clients we offer these products according to the client’s specifications. We even take bulk orders of these and also ensure that it reaches the customers on time. We are an ISO 9001:2008 certified company. These products are highly acknowledged by the clients for their sturdy construction, corrosion resistant and optimum performance. Owing to these feature our products are highly demanded in the Pharmaceutical industries, bulk drug industries, petro-chemical industries and agriculture industries.

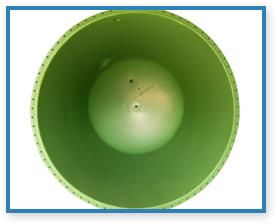

Anti Static Halar Coated Receive

Description / Specification of Anti Static Halar Coated Receive

We are involved in offering a wide range of Anti Static Halar Coated Receive to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Anti Static Halar Coated Receive. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

P. V. D. F. (Polyvinyledene Fluoride)

36740.jpg)

PVDF, Polyvinyledene Fluoride is a highly non reactive and pure thermoplastic fluoropolymer. It is also called as HYLAR.

PVDF is a special plastic material from the fluoropolymer family. PVDF coating is a special purpose coating that can be used in various applications that require highest purity, strength, resistance to solvents, acids, and bases and for low smoke generation during a fire event.

PVDF coated components are used extensively in the high purity semiconductor market (low extractable values), in the pulp and paper industry (chemically resistant to halogens and acids), nuclear waste processing (radiation and hot acid applications), chemical processing (chemical and temperature applications), and water treatment. This fluoropolymer can also meet specifications for the food and pharmaceutical processing industries. At elevated temperatures PVDF can be dissolved in polar solvents such as organic esters and amines, making them practical for use in corrosion resistant coatings and durable architectural finishes on building panels. PVDF coatings are easy to melt when compared with other fluoropolymers because of its low melting point of around 177°C, PVDF can be injected, molded or welded.

Teflon Bellows

D V Polymers is counted amongst renowned manufacturer and supplier of PTFE Products and Components. PTFE & filled PTFE products such as PTFE Rods,PTFE Bushes, PTFE Moulded Sheets, PTFE Skived Sheets, & PTFE Machined components TFE Gaskets, PTFE Bellows in variety of grades such as Virgin PTFE, Glass Filled PTFE, Carbon Filled PTFE,Graphite Filled PTFE, Bronze Filled PTFE… etc.

We are able to supply huge quantity and also we can support for few quantity. Typical components also we will make as per customer drawings, Sizes Available as per Customer Requirement

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.