D.V.POLYMERS INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to D.V.POLYMERS INDIA P.LTD.

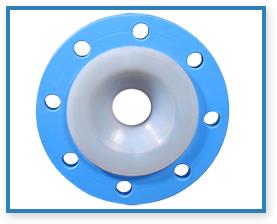

E. T. F. E. Tefzel Coatings

We are identified as one of the leading brands in manufacturing and supplying of ETFE Tefzel coatings. Customers recognize us as the renowned suppliers of ETFE. In order to sustain the quality of the products we ensure the raw materials required to manufacture the product is brought from the trusted vendors in the market well known in the market for quality and trust. Also advanced machineries and techniques is used to manufacture these ETFE products in order to meet the customer expectations in terms of quality. Further is strictly tested on various quality parameters by our quality experts in order to meet the defined quality standards. Also we ensure that all our ETFE products is according to international quality standards. In order to meet the needs and requirements of the clients we offer these products according to the client’s specifications. We even take bulk orders of these and also ensure that it reaches the customers on time. We are an ISO 9001:2008 certified company. These products are highly acknowledged by the clients for their sturdy construction, corrosion resistant and optimum performance. Owing to these feature our products are highly demanded in the Pharmaceutical industries, bulk drug industries, petro-chemical industries and agriculture industries.

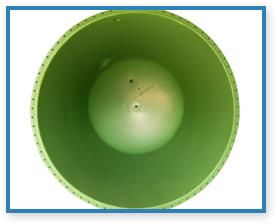

Anti Static Halar Coated Receive

Description / Specification of Anti Static Halar Coated Receive

We are involved in offering a wide range of Anti Static Halar Coated Receive to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Anti Static Halar Coated Receive. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

P. V. D. F. (Polyvinyledene Fluoride)

36740.jpg)

PVDF, Polyvinyledene Fluoride is a highly non reactive and pure thermoplastic fluoropolymer. It is also called as HYLAR.

PVDF is a special plastic material from the fluoropolymer family. PVDF coating is a special purpose coating that can be used in various applications that require highest purity, strength, resistance to solvents, acids, and bases and for low smoke generation during a fire event.

PVDF coated components are used extensively in the high purity semiconductor market (low extractable values), in the pulp and paper industry (chemically resistant to halogens and acids), nuclear waste processing (radiation and hot acid applications), chemical processing (chemical and temperature applications), and water treatment. This fluoropolymer can also meet specifications for the food and pharmaceutical processing industries. At elevated temperatures PVDF can be dissolved in polar solvents such as organic esters and amines, making them practical for use in corrosion resistant coatings and durable architectural finishes on building panels. PVDF coatings are easy to melt when compared with other fluoropolymers because of its low melting point of around 177°C, PVDF can be injected, molded or welded.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.