Critical Fluid Extraction

Cybernetik has developed a state of the art supercritical fluid extraction system that can help increase extraction efficiency and yield of oils and oleoresins, in comparison to traditional extraction techniques. The system can be used for extraction from herbs and spices such as oregano, hops, turmeric etc.

When carbon dioxide is compressed and heated to a certain pressure and temperature, it is referred to as a supercritical fluid. In this state, carbon dioxide exhibits solvating properties of a liquid and the diffusivity of a gas. This makes it a powerful medium for extraction of natural oils from organic materials.

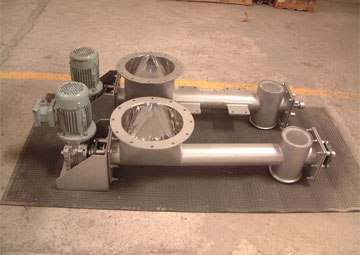

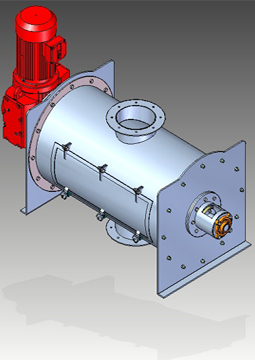

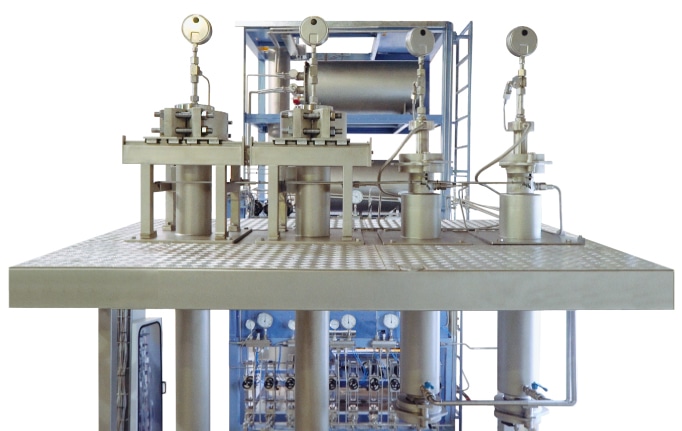

The system consists of a high pressure system ranging from 300 to 600 bar with high end pumping technology, extraction vessels, gas-liquid separation chambers and complex pressure regulating valves. All these equipment are controlled and monitored through a user-friendly HMI and SCADA system.

The benefits of using SCFE systems by Cybernetik include:

- Higher extraction efficiency

- FDA approved process due to use of carbon dioxide as a separation medium

- High product purity

- Negligible decomposition and damage of extracted oils due to mild processing temperatures

- Easy to clean and maintain. Different oils can be extracted from the same system.

- Lower operational costs due to reusability of the carbon dioxide

Cybernetik offers fully automatic as well as semi-automatic systems, based on the production scale of the user.

Capacities available:

- 5 liters

- 25 liters

- 100 liters

(capacities indicate the volume of the extraction vessel, i.e volume of the natural product that oils will be extracted from)

Applications:

- Decaffeinating of coffee and tea

- Extraction of essential oils and oleoresins

- Extraction of flavors from natural resources

- Extraction of ingredients from spices and red peppers

- Extraction of fat from food products

- Fractionation of polymeric materials

71147.jpg)