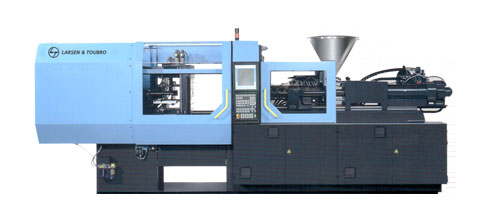

Injection Molding Machine

We offer Injection Moulding Machine from L&T (Larsen & Toubro) INDIA, which is one of the Biggest Group Company in India.

Under Plastic Division L&T manufacture Plastic Injection Moulding and Auxiliaries like, De-Humidifier, Hopper Loader and Hopper Dryer etc.

The Machines are of German Design and also they have own R&D Department for implementing latest Technology.

- S-Tech Series Injection Moulding Machines

These Machines are cost effective Machine with LNC5 Controller. S-Tech Series is presently available in lower and medium tonnages from 600 kN to 2750 kN for parts weighing from 20 gms to 1500 gms. S-Tech is ideally designed to meet the process requirements of a variety of molding jobs that require optimal performance with a reasonable initial investment. S-Tech derived from the proven De-Tech series of Machines, S-Tech encompasses all the benefits of unified design

- De-Tech Series Injection Moulding Machine

De-tech is the entry level closed loop machine offering the best value for money. The De-tech machines have a computer optimized 5-Point Twin toggle clamping mechanism that offers good kinematics and secure the molds while clamping. The Injection units have a modular selection to enable you opt for the right machine for your molding requirement. The LNC5 control offers the molders with an assortment of options and features that make your molding a pleasure. De-tech machines are best suited for entry level moldings and mass productions with reduced cycle time requirements and for those operations that require returns in a short time. De-tech machines comes in a variety of sizes ranging from 40T to 650T and shot weights from as low as 21 gms to 6.5 kgs

- Ace GenXt Series Injection Moulding Machine

Ace is a precision, high quality Injection Moulding Machine. The Ace GenXt machine series is perfectly matched to user needs in the clamp force range from 400kN to 10,000 kN. With modular options for injection unit, screw, pump rating and drive. The specifications are enhanced better level of accuracy and also shot consistent, with powerful 5-point double toggle, ugged machine construction, and an ergonomic operator interface. The modular and ergonomically design enhances economy, reduces maintenance costs, set-up time, and spare parts stock requirements, and makes operation more efficient and safer. And it is a proactive concept capable of coping with upcoming new challenges