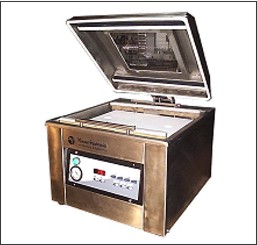

Vacuum Packaging Machine Table Top Mini

Model name : Table Top Mini Vacuum Packaging Machine

Vacuum Chamber size : 365 Width x 375 Length x 80 mm Height.

Over all Size : 415 x 490 x 350

Construction : Complete SS 304.

Lid : Transparent Acrylic.

Gas : Optional with 4 nozzles.

Vacuum monitoring & control : German, dial gauge & vacuum sensor optional

Electrical consumption : Maximum 1 KW, can be operated on domestic connection.

Packing cycle : 2 to 3 Cycles/ minute depending upon the product to vacuum packed.

Winner special :

Maintenance free Vacuum actuator for lifting sealing bars.

Fiber glass sealing bars for short circuit protection.