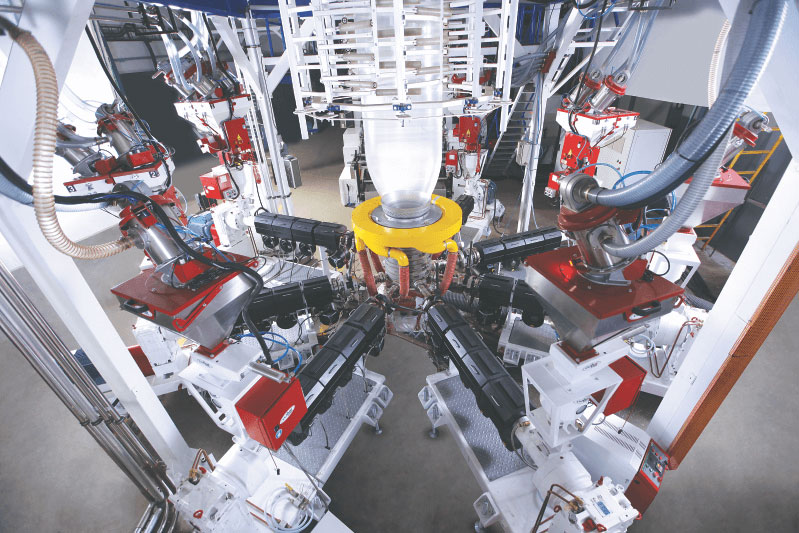

Injection Moulding Machines

Winpack series Toggle Injection moulding Machines are designed with CAD optimized high speed, five point twin toggle locking mechanism with use of graphite impregnated bushes & high tensile chrome plated tie bar to provide fast and precise mold closing and opening system.

As toggle machines, the Winpack series is characterized by faster clamp movement, robust performance, higher energy efficiency, increased productivity.

These are high speed machines, generally used in fast cycling applications. Large volume accumulator assures high speed injection.

Automatic mold height & tonnage setting through sun gear mechanism with rotary encoder enables easy operation of mold setting, resulting in advantages like positive drive, no backlash, high rigidity, increased mold safety and longer life.

Winpack series machines are available with VDP system as a standard feature.

Winpack series ranges from 125 to 350 ton clamping force capacity.