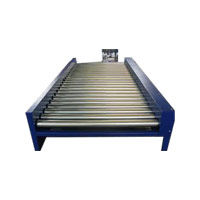

Semi Automatic Box Strapping Machines And Low Table And Regular

We have gained a reputable position as a manufacturer of Semi Automatic Box Strapping Machine which is easy to use, durable and has high productivity. All the components used to manufacture this machine are of best quality and are resistant to wear, available to the clients at negotiable prices. High Table ( HT ) & Low Table (LT ) models are available to suit different product line requirements. We are affianced in supplying Low Table Strapping Machine, Horizontal Strapping Machine in Indian and International Market. Our machine is used is used for binding paper cartons, wooden boxes etc. using PP straps. It also widely appropriate for foreign trade, printing, post, medicines, light industry and others.

69541.jpg)