Thyristor Controlled Capacitors

The process to make steel on the fingertip control.

Automatic weighing controls of Iron Ore, Lime and Coke.

Automatic transfer to Kiln through various conveyors.

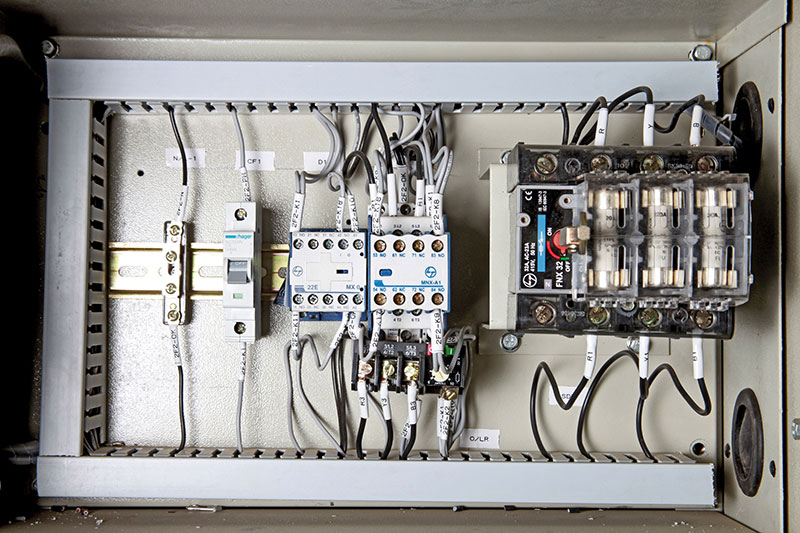

Temperature and Pressure monitoring & control of the Kiln.

A complete operator friendly HMI to control the process.

Remote management and data logging possible.

Energy Recovery Boiler automation.

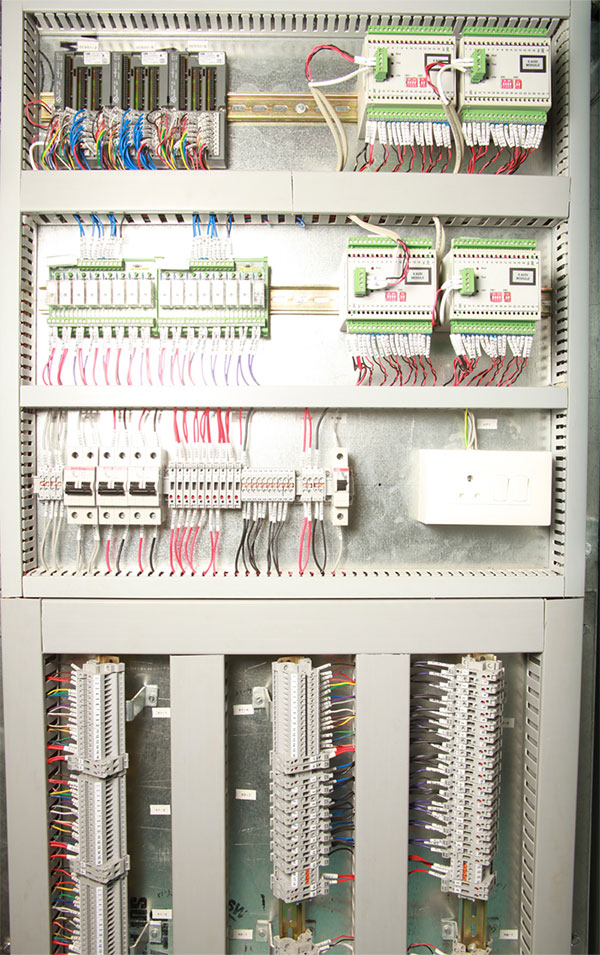

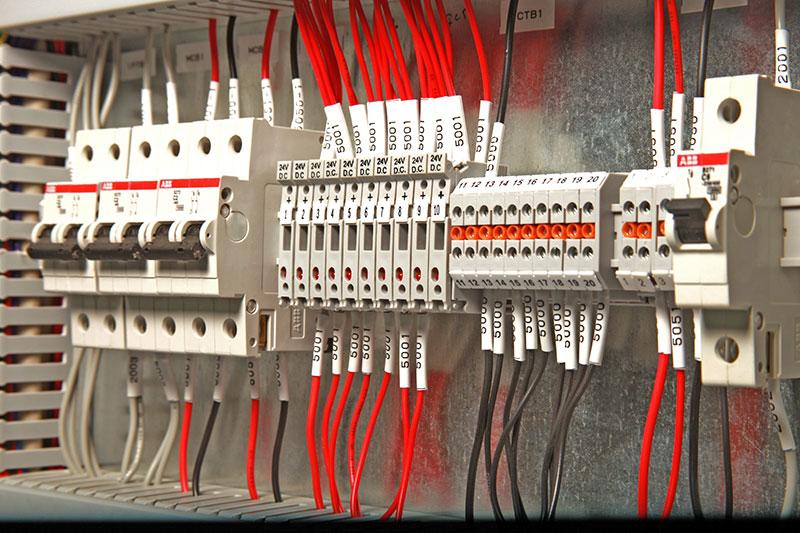

Modular PLCs communicating with each other on high-speed bus.

Data management and ERP interface.