VASANTHA TOOL CRAFTS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to VASANTHA TOOL CRAFTS P.LTD.

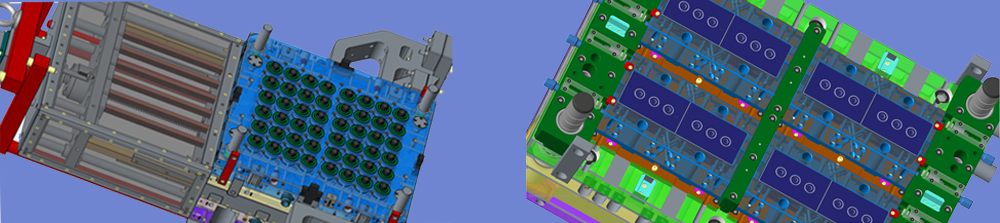

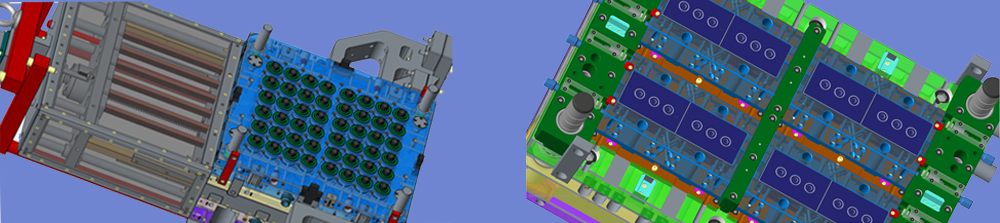

Mould Design

Vasantha with its approach for innovative design and manufacturing has been always ahead in developing complex high cavitation critical moulds with optimal cycle time to achieve high productivity levels

The highly skilled professionals with their vast experience are able to design moulds which can sustain continuous runs with minimal maintenance by which the customer benefits in high up time of the moulds in turn better productivity levels. With the combination of all the above skill sets and keeping in pace with ever increasing challenges for high performance tools ,Vasantha has been very successful in designing below mentioned various moulds using latest technologies.

Spray Through Cap & Pump Dispenser Moulds

Two shot injection moulds – Core punch back/Over moulding/Rotary/Cube

Un screwing / Un winding moulds

Moulds with In - Mould closing mechanism for flip top caps

Stack

Cube mould

Prototyping

In case of new packaging development, Vasantha works closely with the R & D team of customers to develop the prototype tool. By this we are not only able to ascertain the effective functioning of the mould but also achieve the CTQ / CTF of the parts. Over and above this, it facilitates the customer to take line trials at their filling facility to ensure initial compliance of the product

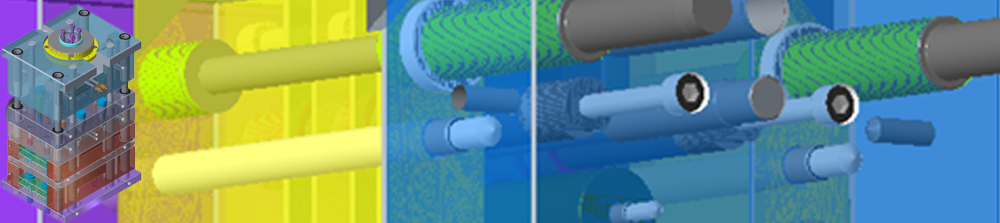

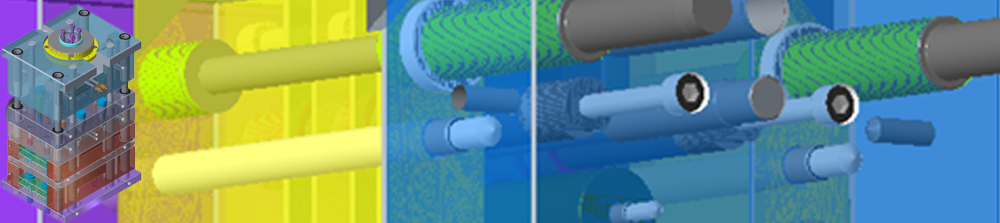

Mould Flow Analysis

At Vasantha, the mould flow analysis is an integral part of designing activity for majority of the moulds, especially for flip top closures and other complex plastic part moulds of high cavitation.

The analysis is done with the help of mouldex 3D or mouldflow software to enable to achieve optimal designs and is shared with customers as part of standard procedure.

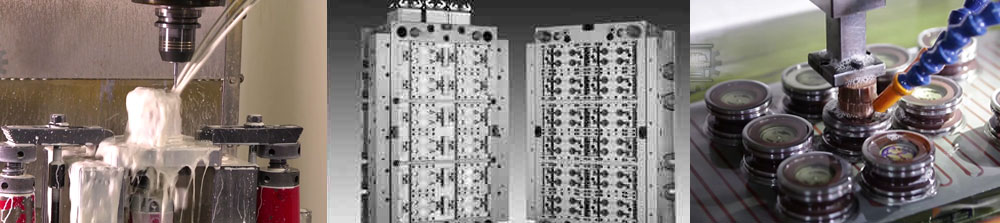

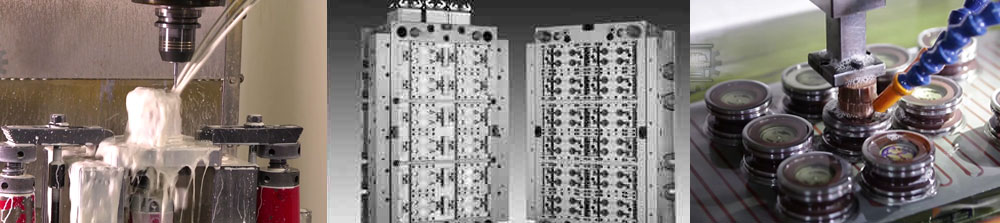

Mould Manufacturing

Deploying modern technology through CAD / CAM in engineering and manufacture on a continuous basis is a thrust area of Vasantha.

Combining the experience with various state-of-the-art mould manufacturing technologies, Vasantha can meet customer requirements with innovative, creative and high standards of work man ship.

Be it a single-cavity, single face pilot mould or a 64+64 multi cavity stack mould, Two shot /Bi color rotary table moulds, Cube moulds, In mould Closing moulds, Un Screwing moulds ,Vasantha has done it all and our expertise can provide the technology suitable for your application.

Project Management

Our Project Management team provides the highest levels of comfort while working closely with your engineering and product development staff and assures that your products and the moulds to manufacture those products are well thought-out with every attention to detail.

Working with Vasantha project management team, our customers are assured of highest level of confidentiality of its projects and products.

Strengths and Merits:

15 member strong team of highly skilled tool makers in assembly line guided by master tool maker with over two decades of experience.

A 10 member strong team of well experienced project engineers having exposure of handling global customers and projects efficiently.

Knowledge to interpret the 3D/ 2D Drawings, Machining processes, Quality Reports and posting customers on a Weekly basis with Photographs of Mould Progress.

Project tracking - Weekly Reviews (Internal and Customer), Weekly updates with photographs of mould progress

Facilitates from DFM to Mould Commissioning.

The vast experience and knowledge of over two decades has helped Vasantha in meeting the customers’ expectations of quality , delivery and value for money.

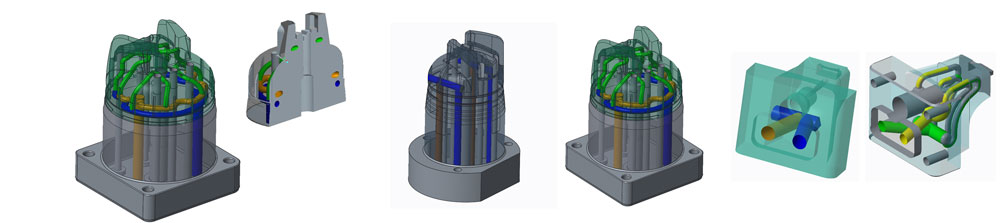

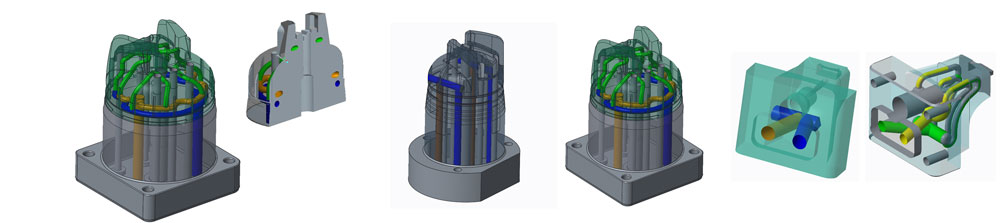

Direct Metal Laser Sintering

Vasantha, keeping in pace with the latest technological advancements in the field of mould making, has inducted leading cutting-edge 3D printing technology into its manufacturing line in the year 2014 for creating the conformal cooling channels in metal inserts.

Vasantha, is probably the only mould design and manufacturing set up in whole of South East Asia to have Direct Metal Laser Sintering ( DMLS) equipment in house.

The equipment from EOS has building capacity by volume - 250 mm x 250 mm x 325 mm (9.85" x 9.85" x 12.8")

Advantages

Conventional moulds have straight-line cooling channels.

Conformal cooling follows the geometry of the part to be produced, makes Cooling to reach difficult areas.

Cooling Time reduces by 40% – 60% for complex profiled parts, resulting in shorter cycle times.

A typical cycle-time reduction for a properly engineered mould using conformal cooling can be 30% to 50%.

High Productivity.

Cooling will be uniform, hence controlled warpage & shrink mark.

Flip Top In Mould Closing (Vertical And Horizontal)

54361.jpg)

Description / Specification of Flip Top In Mould Closing (Vertical And Horizontal)

We are involved in offering a wide range of Flip Top In Mould Closing (Vertical And Horizontal) to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Flip Top In Mould Closing (Vertical And Horizontal). Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Un Screwing

Description / Specification of Un Screwing

We are involved in offering a wide range of Un Screwing to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Un Screwing. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Stack

Description / Specification of Stack

We are involved in offering a wide range of Stack to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Stack. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Spray Through Cap And Pump Dispenser Moulds

Description / Specification of Spray Through Cap And Pump Dispenser Moulds

We are involved in offering a wide range of Spray Through Cap And Pump Dispenser Moulds to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Spray Through Cap And Pump Dispenser Moulds. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Personal Care

Over the years Vasantha has the privilege of working with some of the most demanding customers which has translated in to developing our skills to meet such requirements.By this we have been successful in establishing Vasantha as a one stop shop solution provider for the caps and closure moulds to many a critical applications in personal care market segment.

The maximum percentage of moulds designed and manufactured by Vasantha is for this segment and we are able to consistently maintain the lead position by virtue of our creative and out of the box thinking.

Food And Beverage

Description / Specification of Food And Beverage

We are involved in offering a wide range of Food And Beverage to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Food And Beverage. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

House Hold Care

Vasantha over the years has been successful in penetrating the house hold care segment both in India and abroad.

In the recent past we have designed and manufactured moulds with laser sintered (3D printed) cores having conformal cooling channels using DMLS process in this segment.

By this we are able to enhance productivity by improvising the cooling of the plastic component by almost 35 % to 40 %. Apart from this we can get an excellent part quality in terms of aesthetics and functionality.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

54361.jpg)