THERMODYNE ENGINEERING SYSTEMS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to THERMODYNE ENGINEERING SYSTEMS

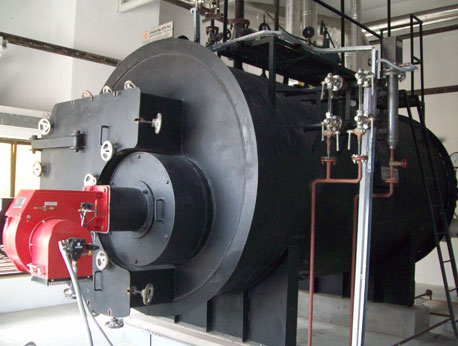

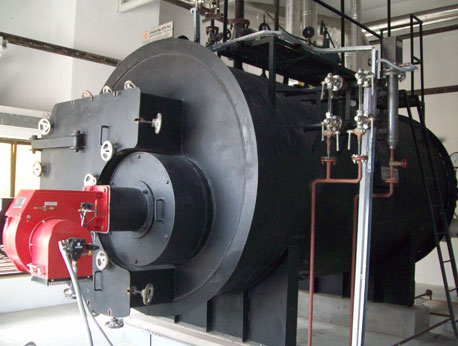

Savemax Oil And Gas Fired Boilers

Savemax – Oil/Gas Fired Boilers is the conventional three pass smoke-tube design Oil/Gas fired steam boiler having an internal water cooling furnace area. The superior and features make it the Boilers ideal choice for process heating requirements of the industry today.

The 3-passes design packaged boilers are most suitable to the burn fuels like heavy/light oils & Gasses. The high combustion volume along with large water and Steam holding capacity makes it the most boilers in its classes.

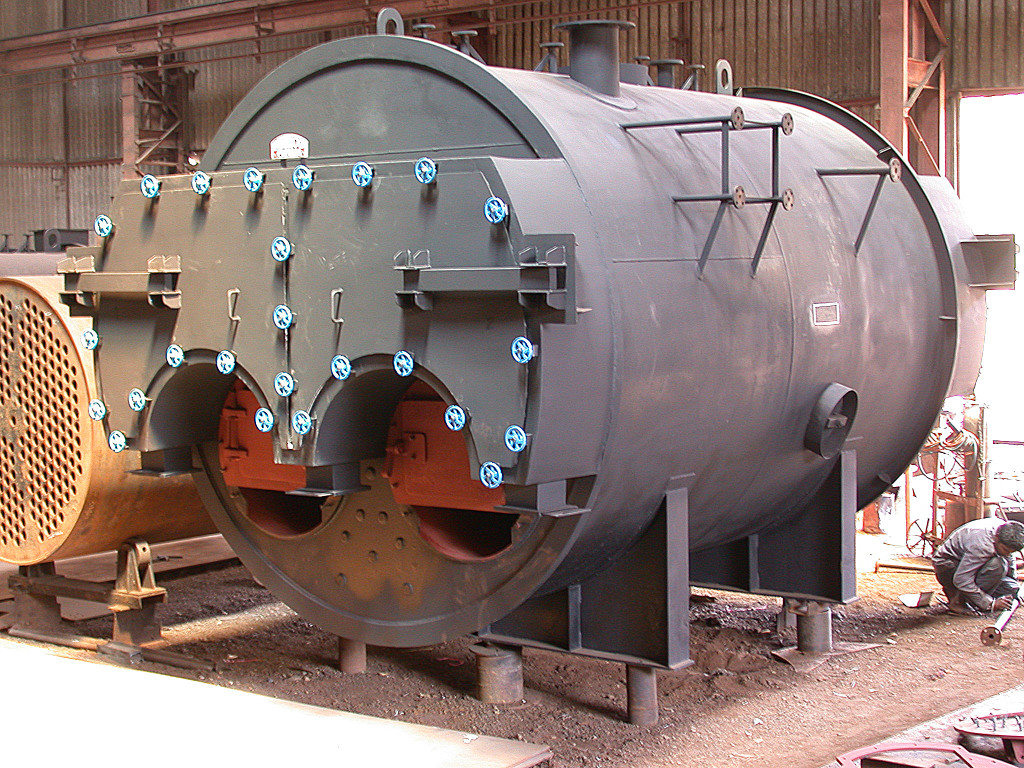

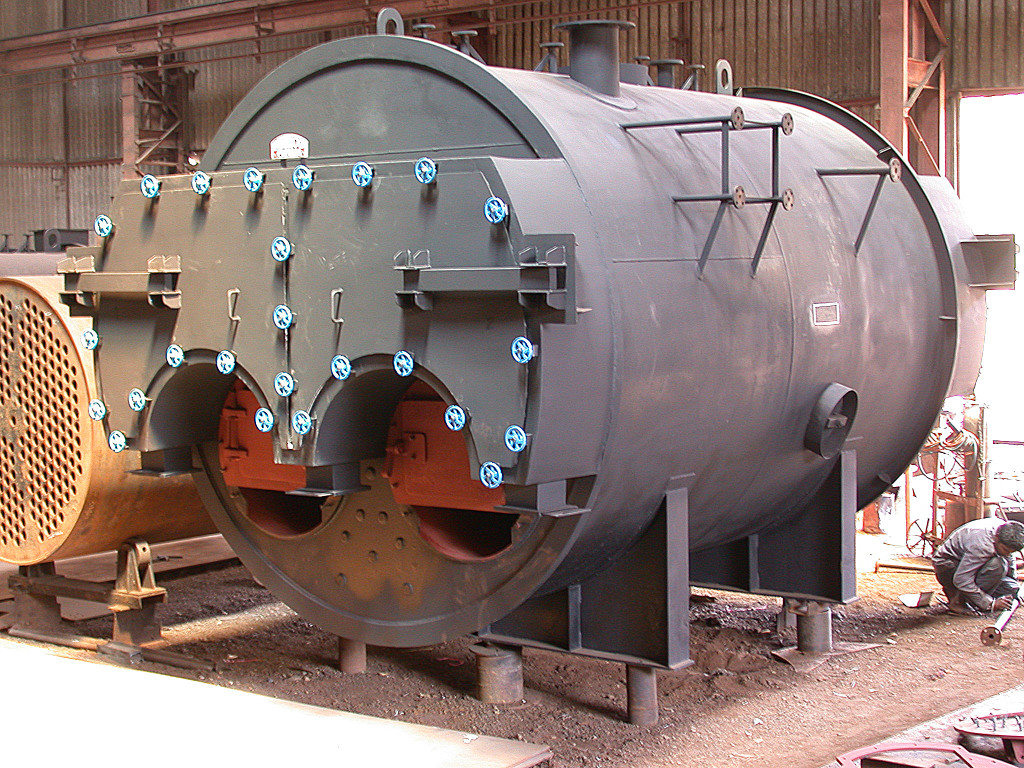

Intech Three Pass Internal Furnace Packaged Type Boilers

Intech (3 pass Internal Furnace Packaged Type Boiler) Boiler is the conventional three pass smoke-tube design coal / wood fired steam boiler having the internal furnace. This packaged Type Boiler comes in dry back, semi-wet back, and fully wet-back options and is most suitable for a manual firing of Solid Fuel likes coal, wood or briquettes.

The furnace of the boiler is completely submerged in the water, this helps in capturing the maximum heat from the furnace all around its periphery and the grate bars are placed in the furnace to ensure desired grate area for Fuel Firing. The fuel of packaged type Boiler is fired on the grate and the flue gases travel from the furnace till the flue gas outlet through the second and third pass smoke tubes, reversing from smoke boxes on their way out. An induced draft fan is provided in the Boiler assembly, for proper combustion and balanced draft in the furnace. This conventional design also ensures effective distribution of thermal and mechanical stresses in the heating equipment.

Combitherm Three Pass Smoke Cum Water Tube Type Boiler

Combitherm Boiler is a unique membrane design water wall type boiler which combines the advantages of both water tube & smoke tube steam boilers. The radiation zone of the furnace is covered on three sides by wall of water tubes forming the first pass and the conventional smoke tube shell has tubes lined up forming the second and third pass of flue gases. Thus, the water wall furnace recovers the radiation heat of the furnace and the smoke tube shell provides large water & steam holding capacities to give the maximum advantage.

Combitherm Ultra Boilers

Combitherm Ultra Boilers are factory assembled unit, installed on a skid base frame requiring minimum site work for installation. This steam boiler too, operates on the function of both water and smoke tube combination type steam boiler. This unique and compact design is one its kind, with amazing fuel feeding flexibility (wood, coal, briquettes, petcoke, rice husk etc.) and redefined water & flue gas circulation for enhanced heat transfer to achieve maximum operational effectiveness.

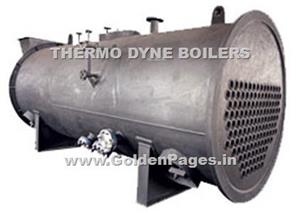

Agromax

Agromax – The Single Pass Boilers With External Furnace are a multiple solid fuel fired boilers in shell & tube type. The Agromax external refractory-lined chamber (in customer’s scope) will burn kind of solid fuels likes badasses, coals, rice husks, saw-dusts, woods, groundnut shells etc. thereby giving flexibility and simple operation. The Agromax – The Single Pass Boilers With External Furnace system operates on balanced draft and therefore, the flue gases from the chamber travel through the smoke tubes within the shells & tubes type boilers, thereby manufacturing steams at the low value. A heat recovery unit within the type of an Air or Water pre-heater is also provided to reinforce the potency of the systems by convalescent waste heat from flue gases going out of the boiler.

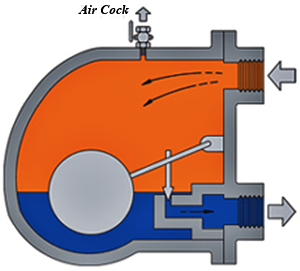

Electra Electrode Type Steam Boilers

Operating Principle – ELECTRA – Electrode Type Steam Boilers differs in principle from any other method of heating water or producing steam as the water within the shell is used as an electrical resistance through which the current is passed. This causes a rise in the temperature of the water. As the amperage rises, so does the temp. of the water, leading to the generation of steam. The best part of this part is the quick response to the steam requirement at the process end. The only limitation of this design is the charges due to high electrical consumption.

Revosteam Water Tube Coil Type Boiler

Revosteam – Water Tube Coil Type Boiler

REVOSTEAM is the conventional forced circulation type water tube coil type boiler incorporating the unique principle of combustion known as ‘Reverse Flow’. This flow of flue gases enhances the combustion efficiency and also allows a high rate of heat release to the surrounding water coil. It can be offered in both IBR and Non-IBR designs

Instatherm Hot Water Generator

Instatherm – Hot Water Generator

Instatherm is the efficient and cost-effective way to generate hot water instantly. It is a packaged type, silent and instant hot water generator. It is designed exclusively catering to the hot water requirements of Hotels, Hospitals, Resorts, swimming pools, Dairies, Laundries and various other process industries.

Wastetherm Waste Heat Recovery Boiler

Wastetherm – Waste Heat Recovery Boiler

Fuel is money. The more fuel we burn in a Steam boiler, the more money is spent. Hence, even a few percent saving in fuel bills amounts to huge savings annually. Due to this, we provide novel products like Wastetherm, the Waste Heat Recovery Boilers. As the name suggests, the heat going waste from the process like flue gases of Diesel Generator sets is utilized in these boilers to generate hot water or steam. Since no fuel is fired, whatever heat we recover in the boiler is free of cost.

Thermair Hot Air Generators

Thermair, hot air generators consist of a shell and tube type heat exchanger which is duly insulated to prevent radiation losses. The ventilation blower fitted alongside blows fresh air over the combustion chamber and the set of smoke tubes. In oil / gas fired options, an imported mono-block type fully automatic burner is provided for combustion of fuel.

Thermair can also be offered in solid fuel firing options. A dust-proof, pre-wired control panel is also supplied as a standard supply to control the operation of the unit based on customer requirements.

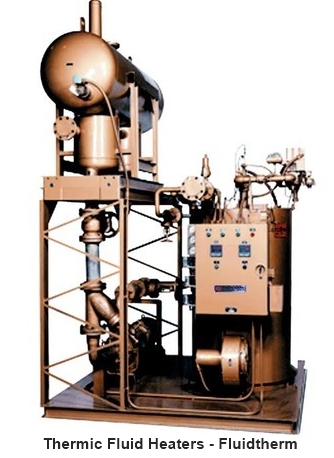

Thermic Fluid Heater Fluidtherm

Description / Specification of Thermic Fluid Heater Fluidtherm

We are involved in offering a wide range of Thermic Fluid Heater Fluidtherm to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Thermic Fluid Heater Fluidtherm. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

High Pressure Boilers (Powertherm)

50262.jpg)

Description / Specification of High Pressure Boilers (Powertherm)

We are involved in offering a wide range of High Pressure Boilers (Powertherm) to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of High Pressure Boilers (Powertherm). Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Pressurised Condensate Recovery Module

Pressurised Condensate Recovery Module includes energy saving, water treatment charges & also includes calculations for potential savings.

In this energy conscious environment, one always looks forward to save and reuse the maximum possible magnitude of energy. Returning the highest possible percentage of condensate to the boiler offers an exceptional return on the investments by helping to cut energy and maintenance costs. This pressurized system also ensures a considerable enhancement in the Boiler operation efficiency.

Industrial Fans And Blowers

In a Steam Boiler operation assembly, Industrial Fans and Blowers i.e. Forced Draft fans are used to draw air into combustion chamber, where it mixes with the fuel being supplied. FD fan is used to regulate appropriate amount of air to fuel ratio in combustion chamber to maximize the fuel efficiency.

Induced Draft fans are used in industrial steam boilers to draw flue gases from the combustion chamber and through the rest of the boiler assembly (Air Pre-heater, Dust Collectors, ESPs etc.) to the stack. Induced Draft fan is always assembled before chimney.

Pressure Vessels And Accumulators

Thermodyne Boilers provide pressure vessels and steam accumulators to meet the unique demands of fluctuating steam loads in plants. These are an excellent solution to plants where the average loads are low, but intermittent steam demands are high. The boilers designed as per the average steam loads are not able to match the peak steam flow requirements here the Steam accumulators provide the buffer to take care of the process steam requirements very effectively.

Chimney

Description / Specification of Chimney

We are involved in offering a wide range of Chimney to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Chimney. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Process Tanks

Thermodyne Engineering System design, manufacture and have commissioned successfully almost all types of process tanks for storage of the variety of fluids. Tanks supplied by us have been installed at some of the leading Process industries both in India and Abroad. The MOC of these tanks can be MS, SS-304, SS-316 to suit the applications as required.

Steam Pressure Reducing Stations

Description / Specification of Steam Pressure Reducing Stations

We are involved in offering a wide range of Steam Pressure Reducing Stations to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Steam Pressure Reducing Stations. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Steam Trap Assemblies

A steam trap assemblies is an essential element of a steam distribution piping system. As steam flows through a pipe, it cools off due to heat losses and converts into hot water; this hot water is called condensate. The function of a steam trap is to release condensate so that only steam remains in the system. In addition to condensate removal, a steam trap also performs air venting function, thereby increasing the thermal efficiency and reliability of the steam distribution system.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.