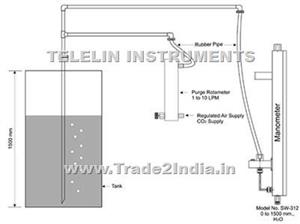

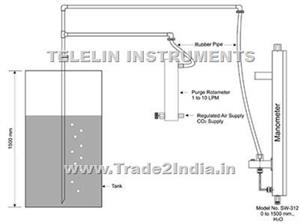

Digital Flow Calibrator

The Digital Flow Calibrator combines the simplicity & versatility of a soap film bubble meter with the speed and accuracy of a microprocessor. With hands free operation, you can still see the bubble, but you also have precision of a digital display with accuracy of a quartz clock. No more tedious bubble formation, bubble watching, timing & flow-rate time calculation. The

DFC-1 accurately calibrates air sampling pumps (vacuum or pressure), rotameters, orifices etc. quickly & reliably with accurate & reproducible results.

FEATURES

| • Primary Standard |

• Multi Function Self Diagnostic for Error free Operation |

| • Flow Accuracy ±2% |

• Automatic Bubble-Feed for hands-free Operation |

| • Wide Measuring Range |

• Adjustable Glass Flow Cell for faster results at low flows |

| • Tracks Multiple Bubbles |

• Measures flow from pressure or Vacuum Source |

| • Auto - Ranging |

• Field Replaceable Glass-Flow Cell |

| • Single or Average Mode |

• Run or Hold Mode |

| • Fully Portable |

• Mains or Battery Operated |

| • Auto Shut-off |

• Optional Portable Printer for Permanent Records. |

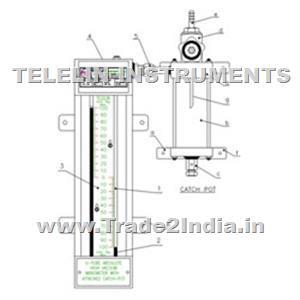

PRINCIPLE OF OPERATION : The DFC-1 gas flow calibrator operates on the principle of traditional soap film flow meter which has been automated with the use of high technology infrared sensors, quartz timing & microprocessor intelligence to provide instant digital read out of gas flow rates. A soap bubble is used to trace the gas flow through a fixed volume high precision glass flow-cell. When the liquid soap bubble passes through the first sensor, it activates a quartz timer, which stops when the soap bubble passes through the second sensor. The microprocessor then calculates the flow rate & instantly displays it on a liquid crystal display.

SPECIFICATIONS :

Measuring Range : 1.0 cc/min to 5.00 Ipm with Auto Ranging facility to cover full scale range of 199.9 ml/min., 1999 ml/min., & 5.00 Ipm.

Display : 3½ digit Liquid Crystal Display with additional indication of LOW-BAT and various Self-Diagnostic System-Errors.

Function : ON RESET - Key to reactivate the system after Auto-Shutoff (in 2 minutes when not in use)

MULTI SINGLE - Modes to effect the measurement continuously for multiple bubble or to limit it to the first bubble.

AVERAGE - Mode to average the last four readings.

Accuracy : ± 2010 of Reading

Flow Cell : Precision, Small-Volume Glass flow cell that is vertically adjustable to provide faster results for Low-Flow applications. It also accepts any type of soap solution. However for higher flow measurement, we recommend our standard solution.

Automatic Bubble : This innovative bubble formation mechanism provides adjustable and continuous stream Formation of bubbles for hands free operation. A large reservoir of soap solution provides long uninterrupted operation without cumbersome process of re-filling after every few minutes.

Power :

• Mains Operated Model - 230 V AC

• Battery Operated Model - 6 V Dry Cell or

• ON indication on Front Panel. Rechargeable batteries Optional at extra charge.

Dimensions : 20 (W) x 15 (D) x 23 (H) cms.

Printer : Optional Impact type, Numeric or Alpha-numeric compact, Portable Printer for permanent record.

Carrying Case : Optional corrosion resistant carrying case to accommodate, DFM-1, soap solution, printer & battery charger.

37452.jpg)

37453.jpg)