TECH PLAASTIC INDUSTRIE P. LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TECH PLAASTIC INDUSTRIE P. LTD

Injection Moulding

TPI is one of the prominent plastic injection moulding companies in India that caters to the automotive, electrical, appliance and renewable energy industries. Injection Moulding is one of TPI’s primary services. With the combined power of cutting-edge machinery and high-end technology, TPI exceeds customer expectations in terms of quality and delivery time.

The infrastructure of TPI’s plastic injection moulding manufacturing unit includes 14 high-precision, conventional injection moulding machines with a range varying from 50 tons to 650 ton. All machines are supplemented with hopper driers, temperature controllers and hot runners. TPI believes in implementing reliable injection moulding principles with a professionally experienced crew. The facility is equipped to cater to injection moulding production 24/7 throughout the year.

Compression Moulding

TPI is an industry leader in high-quality compression and transfer moulding of thermoset plastics. The company was started in the year 1973 to cater to the automotive and electrical industries. TPI provides a wide range of services starting from plastic moulding, mould design, mould manufacture, production, assembly, and much more. We can mould your parts using DMC, SMC, PF, UF and specialise in the manufacture of insert moulded components. TPI has nine hydraulic machines ranging from 100 Tons to 150 Tons.

Thermoset Injection Moulding

Tech Plaastic Industrie is an industry leader in the manufacture of critical thermoset injection moulded components for the automotive & electrical industries. The infrastructure is designed to suit the requirements of demanding Customers looking for reliable source of moulded components at reasonable prices.

TPI processes both high performance Phenolic engineering compounds as well as general purpose phenolics. Our thermoset injection molding factory is equipped with both horizontal type moulding presses as well as vertical type moulding press for its range of insert moulded components.

Mould Manufacture

TPI has the capability to design and manufacture moulds as per Customer design , take trials, provide inspection reports and qualify the mould as quickly as possible.

TPI has the capability to design and manufacture moulds for :

Thermoplastic injection moulding

Thermoset Compression moulding

Thermoset Injection moulding

using Customer supplied drawings and samples. TPI has a team of skilled tool makers, designers and machinists to design, manufacture and maintain moulds .

FACILITIES INCLUDE

Experienced Tool designers and Tool Makers

CAD, CNC EDM Surface Grinding , Vertical Milling Machine

Design Software used ZW Cad, Solid work.

Mould Flow Analysis & Mould Scanning (outsourced), .

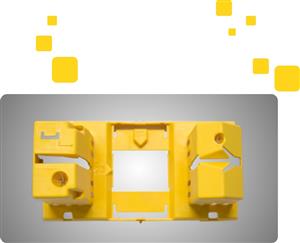

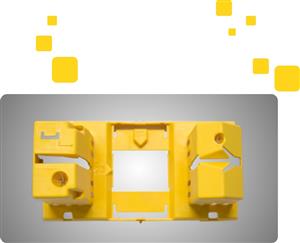

Battery Components

Techplaastic Industrie is a forerunner in the production of a wide range of SLI automotive battery sets and two-wheeler battery sets. The organisational capabilities include the design and manufacture of the hot runner and cold runner moulds for two-wheeler and four-wheeler JIS standard batteries. TPI manufactures battery components like automotive battery case mould and two-wheeler battery case mould. Each is Multi-Fit, N70 SMF, NS60 SMF, NS40 SMF and N55.

3D Printing

Description / Specification of 3D Printing

We are involved in offering a wide range of 3D Printing to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of 3D Printing. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.