TECHNOSHINE ELECTROPLATING

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TECHNOSHINE ELECTROPLATING

Zinc Iron Plating

Zinc Iron Plating

ZINC-IRON PLATING: PROCESS AND ADVANTAGES

Zinc is a shiny metal capable of being alloyed with various other metals. One of these is iron. Zinc-iron resembles zinc in color and other characteristics and both are popular plating metals. Yet, although we perform both types of plating at TECHNO SHINE , some clients actually prefer, zinc-iron plating. They select it more often than straight zinc plating because its properties are more advantageous in several ways including ease of further finishing.

What Is Zinc-Iron?

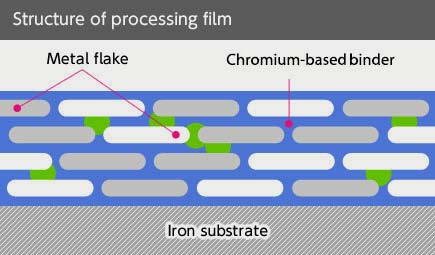

Zinc-iron is an alloy of two metals: zinc and iron. It is the result of zinc plating with the addition of an iron alloy. The content of iron resides between 0.3 and 1.0%. At TECHNO SHINE , our zinc-iron deposits typically contain 0.4 to 0.8% by weight.

The purpose of such product is to improve the existing properties of zinc. Zinc-iron plating works with the substrate metal component to further enhance and improve the properties of the base metal. This gives zinc-iron plated materials some advantages over a non-plated component.

Why Use Zinc-Iron Plating?

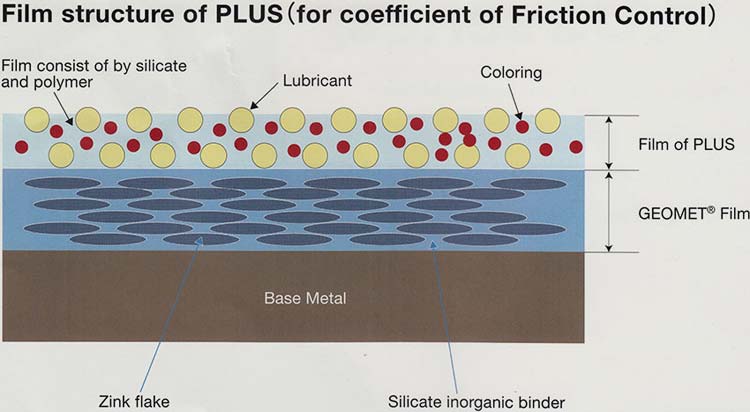

One important advantage of applying a zinc-iron layer to a substrate is improved corrosion resistance. Since zinc has a high resistance, by alloying zinc and iron to plate an item, you are increasing its resistance between 25 and 50%. At the same time, zinc-iron plating provides the substrate layer with other benefits, which include:

Solid weldability

Good ductility

Excellent surface appearance

Even distribution over even edged and irregular components

Superior lubricity

High level of hardness

480+ hours of salt spray resistance

Zinc-iron plating is an excellent choice for components intended to undergo further manufacturing operations such as top coats and coatings, dyes, and waxes. This process also ensures the component will accept almost any color. In the automotive industry, for example, intense black chromate finish is very popular. Overall, perhaps the most attractive feature of zinc-iron plating is its ability to create a blacker part than can be achieved through the use of zinc plating technology.

Employing Zinc-Iron Plating

At Techno shine , we are industry leaders in zinc-iron plating. Companies who want improved and cost-effective corrosion protection for their products understand what the process can achieve for their components. We employ the latest in non-cyanide alkaline techniques to protect the environment while maintaining high quality standards and specifications.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.