TECHNOSHINE ELECTROPLATING

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TECHNOSHINE ELECTROPLATING

Geomet

The GEOMET® product range is a standard worldwide reference for industries requiring high performance thin layer anticorrosion systems. GEOMET® products are completely chrome-free and capable of protecting a wide variety of metallic surfaces. The coatings are well suited for protecting both large and small parts, having either simple or complex geometry. In particular GEOMET® coatings are a worldwide standard for use on fasteners.

GEOMET® 720

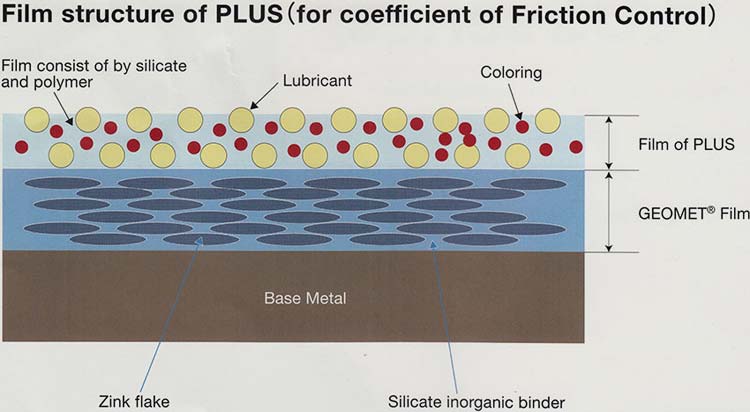

GEOMET® 720 is applied to protect fasteners and many types of metallic parts from corrosion and is used in many industries. It can be combined with PLUS® topcoats to provide a very broad range of friction coefficients. It is the reference zinc flake coating in Asia.

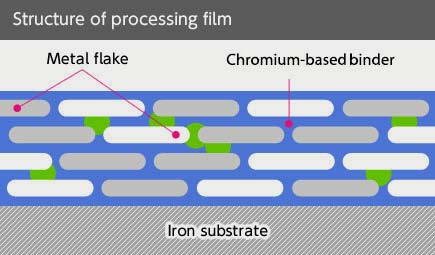

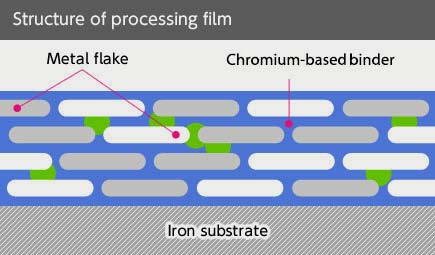

Thin dry-film, non-electrolytic

Water-based chemistry

Passivated zinc and aluminum flakes in a binder, patented chemistry

Metallic silver appearance

Characteristics and performances

The coefficient of friction can be adjusted to targeted values ranging from 0.06 to 0.20 (ISO 16047) with NOF METAL COATINGS GROUP's selected topcoats

Salt Spray Test (ISO 9227)

1000 hrs without red rust

No hydrogen embrittlement

Excellent assembly and multi-tightening behavior (with lubricated topcoat)

Performance maintained at elevated temperatures (up to 300°C)

Paintable coating

Electrical conductivity for most application processes

Bimetallic compatibility with aluminum

GEOMET® 321

GEOMET® 321 is applied to protect fasteners and many type of metallic parts from corrosion and is used in many industries. It can be combined with PLUS®, DACROLUB® or GEOKOTE® topcoats to provide a very broad range of friction coefficients. It is the most widely used product in zinc flake technology.

Thin dry-film, non-electrolytic

Salt Spray Test (ISO 9227)

240 hours without white rust

720 hours without red rust

Water-based chemistry

Passivated zinc and aluminium flakes in a binder, patented chemistry

Chrome free alternative to DACROMET® 320

Metallic silver appearance

GEOMET® 360

GEOMET® 360 has been specially formulated to protect brake discs against corrosion. The brake disc surface can be totally treated with a coating at a thin layer, still providing high performances without any influence on braking characteristics. GEOMET® 360 is obtained from a water-based dispersion of zinc and aluminium flakes. The color of the coating is silver Characteristics and performance*

Cosmetic protection: the brake discs can be seen through the alloy wheels. The aluminium silver color of GEOMET® 360 integrates perfectly with the style of alloy wheels

Braking behavior: the low thickness of the coating on braking surfaces does not damage the quality of braking during the vehicle first use and enables a temporary protection of brake discs surfaces

Temperature resistance (400°C): it enables to keep an excellent corrosion resistance on vehicles

Protection inside the vents: no oxidation inside the fins – better thermal exchange while braking

For after-market, GEOMET® enables to assemble the brake discs on vehicles without pre-degreasing (dry protection)

The stronger corrosion protection of GEOMET® on the hub mounting surface makes brake disc dismounting easier

GEOMET® 500

GEOMET® 500 is applied to fasteners and many type of metallic parts to protect from corrosion, and it is used in many industries

Thin dry-film, non-electrolytic, self-lubricated

Water-based chemistry

Chrome free alternative to DACROMET® 500

Metallic silver appareance

Characteristics and performance

Coefficient of friction: 0,15 ± 0,03 (ISO 16047)

Salt Spray Test (ISO 9227)

240 hours without white rust

720 hours without red rust

No hydrogen embrittlement

Excellent assembly and multi-tightening behavior

Good mechanical damage (test method D24 1312, USCAR 32) and chemical (test VDA 621-412) resistance

Performance maintained at elevated temperatures (up to 300°C)

Paintable coating

Electrical conductivity for most application

Bimetallic compatibility with aluminum

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.