TECHNO LINK CONVEYOR SYSTEMS P.LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TECHNO LINK CONVEYOR SYSTEMS P.LTD

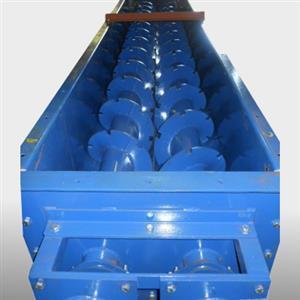

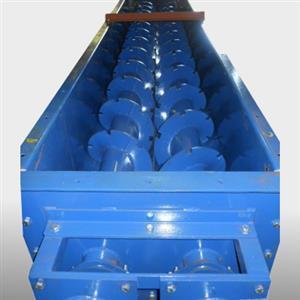

Screw Conveyors

To convey liquid or granular materials horizontally or at a slight incline permitting intermediate emission of the material at various points use Screw Conveyors. Techno Link Conveyor Systems Pvt. Ltd. designs and manufactures horizontal as well as vertical conveyors, basically used in bulk handling industries. It is used as one of the efficient ways for transportation of semi-solid materials like food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat and bone meal, municipal solid waste, to name a few.

It usually comprises of a tube containing either a spiral blade coiled around a shaft, driven at one end and held at the other or a shaftless spiral, driven at one end and free at the other. As per the rotation rate of the shaft, the volume of supplying an object can be loaded. Screw Conveyors in India are functioned with the flow of upward inclined material.

This is a very economical method of elevating and conveying the materials when space permits. The capacity of a given unit rapidly decreases, as the angle of inclination increases. We offer a wide range of Screw Conveyors in India as per the materials conveyed through it and the specifications laid by the clients. It includes Twin Screw Conveyors, Screw Feeders, Paddle Conveyors, Mixing Conveyors, Right and Left Handed Screw Conveyor and Rotary Air Lock Valves. All of these vary from each other as per its operations and the best-suited materials to be conveyed on various temperatures.

Bucket Elevators

ucket Elevators is efficient for handling dry and free-flowing material. So,Techno Link Conveyor Systems Pvt. Ltd. offers best and reliable, simple and sturdy elevators as per the industrial standards.

These Bucket Elevators can elevate a variety of bulk materials from light to heavy and from fine to large lumps. It is often used for transportation of fertiliser, potash and salt, cement, sand and gravel to name a few. It has been proved as one of the most efficient ways to convey bulk materials vertically. It consists of many buckets connected to a belt or a chain with pulleys or sprockets located at the top and bottom of the unit. Also, some of the accessories are used for loading the buckets or picking up the material, getting the discharged material out, maintaining the belt strain and for enclosing and protecting the elevator.

We design and manufacture a wide variety of these elevators based on the characteristics of the bulk material and the process requirements. So you can get one of the best Bucket Elevators that suits your necessities and the material you want to transport.

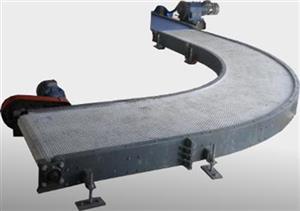

Slat Conveyors

The Slat Conveyors - India is basically installed on the travelling platforms like Airports, metro railway station and many more. Also, as per the customers' demand, the conveyors can be used in various industrial units like chemical industries, glass manufacturing units, assembly lines, etc. If you are facing hassles in conveying heavyweight goods like refrigerators, high-temperature ovens, automobiles, machine parts etc., then get Slat Conveyors - India or Apron Conveyorsfrom Techno Link Conveyor Systems Pvt. Ltd.

Whilst, to form assembling/production lines, jigs or fixtures can be added to the slats. Speed, size and type can deviate from place to place as per the requirement of transporting the materials. The best part of these conveyors is that you can connect one floor to another since it is reliable in nature and caters to wide applications where products can be turned in various directions during transportation. This will help you to transport your goods or appliance floor to floor. To keep our customers stress free, we assure smooth and safe equipment with proper quality control. To get Slat Conveyors / Apron Conveyors to contact Techno Link Conveyor Systems Pvt. Ltd.

Z Bucket Elevators

Techno Link manufactures one of the best Z Bucket Elevators India. Whether your business is into the industrial or agricultural sector, whether your requirements are for loading or unloading, pre-processing or post-processing, for your material handling needs, approach Techno Link. Like the otherbucket elevators manufactured by us, it also incorporates buckets connected to a belt or a chain with pulleys or sprockets located at the top and bottom of the unit. But as the name suggests, Z Bucket Elevators India is in a shape of ‘Z’with its usage as per your comfort level.

These Z Bucket Elevators (India) are an engineered and ruggedly manufactured conveying system designed for continuous and quiet operation. It is utilised to gently-transport a variety of free flow bulk materials in dry, semi-dry and moist conditions. The versatile Bucket elevator is simple to operate and capable of automating your complex processing needs. The most important benefit of installing this Z Bucket Elevator is saving floor space and unnecessary pit requirements in extension or contraction of the vertical and horizontal runs for initial installation as well as future expansion.

The adaptability of this product to deliver product to multi locations from a single or multi-source of supply through its variety of discharge locations and stations forces several industrialists to install this conveying system. We manufacture a highly premium quality range of Z Bucket Elevators. So, if you are in need of such conveying system and are planning to install this unique bucket elevator contact Techno Link Conveyor Systems Pvt. Ltd.

Chain Conveyors

Conveying the material along the path of travel is easy withTechno Link. We are designing, manufacturing, supplying and installing Drag Chain Conveyors for transporting the material along the path of travel. It generally has a low bed height and is an open type. These conveyors are designed for horizontal, inclined and vertical transport of coal, wood, TDF, lime, sawdust, chips and other bulk goods. It is used for handling slightly sluggish, loose, lumpy hot material, abrasive and/or corrosive materials.

The conveyor comprises of flights that are fixed between two strands of chain and drags the material from feeding end to the discharge end in open or closed trough. Drag Chain Conveyors utilises a powered continuous chain arrangement, carrying a series of single pendants. Generally, these conveyors are easy to install and have very minimum maintenance for the clients. These are available in different widths and lengths as per the site requirements. We manufacture these Chain Conveyors as per the defined industry standards and site requirements.

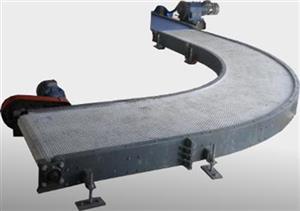

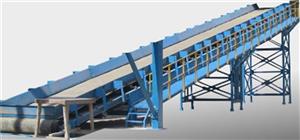

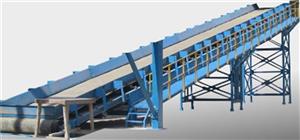

Belt Conveyors

Techno Link Conveyor Systems Pvt. Ltd. manufactures and supplies a wide variety of Belt Conveyors - India, that is used to transporting bulk material from one place to another. TheseBelt Conveyors are able to carry coal, cement, chemicals & fertilizer, paper, and industrial food and agricultural materials.

We manufacture a variety of conveyor belts for conveying different kinds of material available in PVC and rubber materials. Also, these belts can consist of one or more layers of material. Many belts in general material handling have two layers. An underlayer of material to provide linear strength and shape called a carcass and an overlayer called the cover. The carcass is often a woven fabric having a warp & weft. The most common carcass materials are polyester, nylon and cotton. The cover is often various rubber or plastic compounds specified by the use of the belt. Covers can be made from more exotic materials for unusual applications such as silicone for heat or gum rubber when traction is essential. These Belt Conveyors India are manufactured with advanced technology and high-quality raw materials from trusted vendors of the market.

The belt conveyors - India are always updated as per the demands of industry, these conveyors are provided with various required specifications. We design different kinds of belt, that can suit as per your requirement for conveying heavy or lightweight materials, prolonged or shortened in length, etc. Moreover, you can adjust the speeds for the application as needed along with its carrying capacity which can be ample or little. To ensure efficiency and durability, choose the correctTechno Link's belt conveyor - India, for an installation to handle the materials or your product.

Scraper Conveyors

To convey the material via drivers, which push materials along the floor of the housing towards the discharge, use Scraper Conveyors. Techno Link Conveyor Systems Pvt. Ltdmanufactures and designs these conveyors as per the necessities of clients. Scraper conveyors are mainly used to transport coal from the coal face under the coal mine, ash, chips, bark, pallet and many more.

It is a type of flight conveyor, that consists of a trough in which a continuous driven chain with flights is running. The flights are scraping the material over the bottom of the casing. It incorporates the conveyor chain, the chain connectors, the drive wheels, guide wheels, and the scrapers with their attachments.

The design is ideal for slower transportation speeds over short distances, on moderate inclines, or even underwater. Depending on the design, material to be conveyed is brought to the required height at a defined incline and then discharged. We use forked chains, round link chains as well as box scraper chains as a chain type. According to the product and load, we use single as well as double-strand versions.

We also design and manufacture submerged scraper conveyors that highly wear resistant to give long service life. Toothed drive sprockets which locate internally on the chain are mainly used in these scraper conveyors. So, to install scraper conveyor at your site approach Techno Link Conveyor Systems Pvt. Ltd.

Vertiveyors

With the help of Vertiveyors you will be able to convey your bags from downward to upwards without struggling. This will aid you to save your energy and utilise it in some other activity effectively. The fully automatic system integrates powered roller bed in-feed and outfeed conveyors. These are interlocked with the lifting motion of the Vertiveyor in such a manner that they are synchronised to feed or discharge the load from theVertiveyor's flexible lift platforms. We design this conveyor system into various sizes depending on the application of the customer. It can be designed for automatic and manual operations and can also control other conveyors. It is incorporated with a complete control panel that controls all the machine functions.

Apron Conveyors

The Slat Conveyors - India is basically installed on the travelling platforms like Airports, metro railway station and many more. Also, as per the customers' demand, the conveyors can be used in various industrial units like chemical industries, glass manufacturing units, assembly lines, etc. If you are facing hassles in conveying heavyweight goods like refrigerators, high-temperature ovens, automobiles, machine parts etc., then get Slat Conveyors - India or Apron Conveyorsfrom Techno Link Conveyor Systems Pvt. Ltd.

Whilst, to form assembling/production lines, jigs or fixtures can be added to the slats. Speed, size and type can deviate from place to place as per the requirement of transporting the materials. The best part of these conveyors is that you can connect one floor to another since it is reliable in nature and caters to wide applications where products can be turned in various directions during transportation. This will help you to transport your goods or appliance floor to floor. To keep our customers stress free, we assure smooth and safe equipment with proper quality control. To get Slat Conveyors / Apron Conveyors to contact Techno Link Conveyor Systems Pvt. Ltd.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.