TECHNO CONTROLS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TECHNO CONTROLS

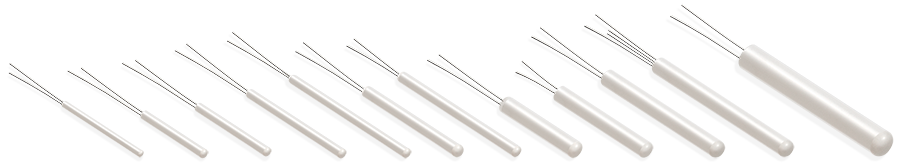

Simplex (Single Element) Stator Winding Rtds

Stator Winding Rtds 62147.jpg)

Description / Specification of Simplex (Single Element) Stator Winding Rtds

We are involved in offering a wide range of Simplex (Single Element) Stator Winding Rtds to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Simplex (Single Element) Stator Winding Rtds. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Duplex (Double Element) Stator Winding Rtds

Stator Winding Rtds 62148.jpg)

Product Overview

Duplex stator winding RTD provide extra protection for Motors & Generator. The Second element is used either incase of damage of one element or use one element to display temperature at machine & second element for control room.

Main Features

Slim dimensions to get inserted in between windings

Bifilar wound slot resistance thermometer design that prevents induction voltage resulting in measurement errors

Resistance to shock, vibration and pressure

Withstand of VPI(Vaccum Pressure Impregnation) Process

High Dielectric Strength

ATEX /IECEx approve model available for equipment used in hazardous area

Atex And Iecex Approved Sensors

Main Features

Slim dimensions to get inserted in between windings

Bifiliar design that prevents induction voltage resulting in measurement errors

Resistance to shock, vibration and pressure

Withstand of VPI(Vaccum Pressure Impregnation) Process

High Dielectric Strength

RTD certified as Increase safety “e” and Intrinsically safe ‘i’ approved for zone 1 and 21

EC-Type examination certificate no: DNV-2008-OSL-ATEX-40059U, rev. 1

IECEx certificate no: IECEx DNV 14.0014U and IECEx SIR 16.0033U

Complies with European standard for electrical apparatus for

Explosive gas atmosphere : ATEX EU Directive 2014/34/EU

IEC 60079-0:2012 (General requirements)

IEC 60079-7:2015 (Increased Safety ‘e’)

IEC 60079-11:2012 (Intrinsically Safe ‘i’)

Bearing Temperature Sensor

Product Overview

BTDs are Bearing Temperature Detectors. They are also called Bearing Temperature Sensors.

Bearing temperature detectors are installed in stationary bearing casing and monitors bearing temperature.

Bearing temperature is an important parameter of heavy rotary machines and it indicates bearing health in rotating equipment.

Rise in bearing temperature suggest possibilities of problem in oil film or alignment of shafting.

BTDs give early detection of bearing problems and it prevents further damage of machine.

The measuring elements are located in proximity of tip in order to measure correct reading.

Btds With Bayonet

BTDs with bayonet

Sensor with bayonets are widely used for this application.

This design offers quick mounting or removal of sensor.

This kind of construction also offer firm contact with metal parts for fast response.

Also this design is quite rugged and suitable for environment where vibration is present.

Just like other design, there are many options available in this designs and our product range includes various dimensions, connecting threads, option of single or double notch etc.

Btds With Extension Cables

BTDs with extension cables

This kind of BTDs are available with inbuilt or integrated extension leads.

Length and construction of the extension leads can be customized

We offer various kind extension leads like PTFE/FEP/Polyamide/PVC etc with or without screening.

Color codes can also be customized.

Just like previous design, it is available with various kind of compression fittings.

Also, option of electrical insulating sleeves on metal sheath is available.

Btds With Terminal Head

BTDs with terminal head

In this kind of design, terminal head is provided to connect signal cable with sensor.

This design is suitable when termination of signal cable is far from sensor.

Terminal heads are available in various material like aluminum, nylon or SS.

Normally, mounting of terminal is on spring loaded assembly

This head are available with Ingress protection certificates.

There are several options like number of cable entries, cable entry size etc.

Movable or fix (welded fitting) of required size can be provided.

Also, we also provide insulating sleeve on sheath if required.

Btds With Special Design

BTDs with special design

As the name suggest, we offer special designed BTDs.

This designs includes various options like

100% electrical insulated

BTDs with various connectors

BTDs with special mounting arrangements

This design are truly customized and available in various designs.

We also execute development orders for BTDs which are not mentioned in our standard product list.

Wire Wound Rtd

General description for RTD elements

Temperature is one of the important basic or fundamental quantity of a matter and it defines the thermal energy of the matter. It is measured in various units like °C, °F, and °K. All these units are quite well defined by International Temperature scale ITS 90. Among various methods of temperature measurements, thermocouples, resistance thermometers and thermistors are most popular. The reason being they provide electrical signals, which can be connected to, sophisticated indicating, controlling and recording instruments. Over the range of –200 deg c to +962 deg C, accepted standards is the Standard PRT i.e. Platinum Resistance Thermometers. The basic principle of resistance thermometry is that the resistively of metal depends upon it’s temperature. It is an absolute method of measurement (As compared to thermocouple which measures temperature difference) For a particular metal, a curve can be obtained for resistance versus temperature. The base metal used in resistance thermometry are Platinum, Copper and Nickel. Since early days, resistance thermometry has gone to considerable changes and they are now extensively used in industries. At temperature below 650 deg C, the industrial resistance thermometer are now more accurate and reliable than any other sensors. The increase in use of microcontroller based linearised instruments increases the choice of RTDs .

Among all the base metals, Platinum is now a days the best choice in the industries. Platinum being a noble metal retains its characteristics for longer time. For wide temperature range Platinum Resistance thermometer follows the equation as defined below,

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

Stator Winding Rtds 62147.jpg)

Stator Winding Rtds 62148.jpg)