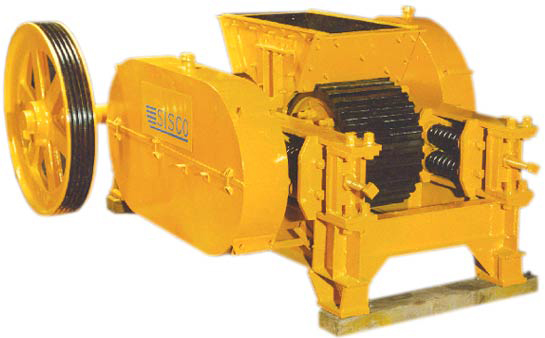

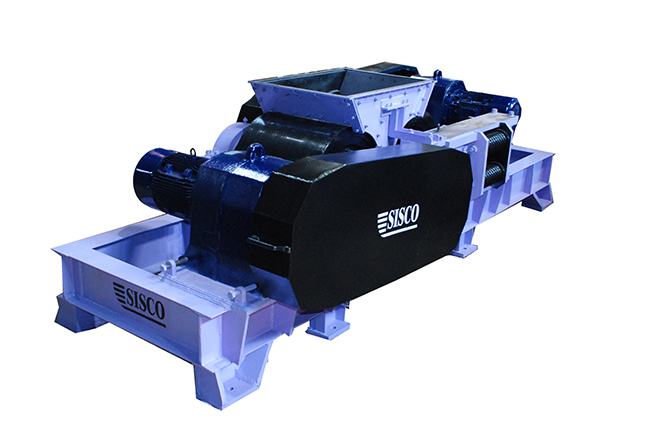

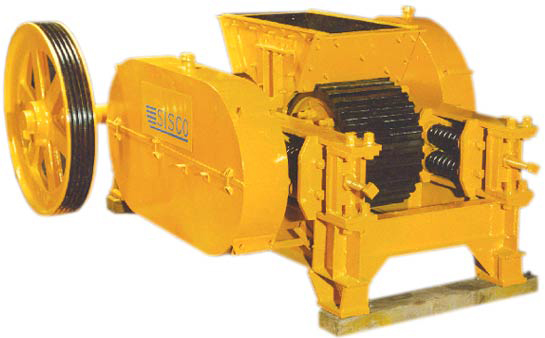

Double Roll Crusher

APPLICATION

The Roll Crusher usually saves head-room and weight, compact in structure and economical in first cost. lt is capable of large output AT SMALL RATIOS OF REDUCTION. For these reasons, the roll crusher lends itself to portable use or for fine crushing where ratio of reduction does not exceed 3 to 1. Corrugated rolls of different pitch and depth are used for greater RATIO OF REDUCTION and can take BIGGER FEED SIZE.

CAPARCITY AND REDUCTION RATIO

The double roll type of crusher pinches the aggregate only once. To avoid excessive wear upon the roll tyres, it is important that the pinch should be immediate, positive and without slippage. Consequently, larger feed sizes should be avoided, and the ratio of reduction should be kept within the 3 to 1 limit. Any attempt to exceed the permissible ratio of reduction c causes slippage which leads to increased wear upon the tyres, excessive spring action, oversize product and undue unkeep expense. Refer to table on back page for capacities and maximum size of feed recommended. ‘SISCO’ CD-Series Roll Crushers successfully Crushes Aggregates, Limestone, lron Ore, Dolomite Coal etc.

CONSTRUCTION

‘SISCO’ Double Roll Crusher is a very substantially built machine. The longitudinal frame members are heavy steel joist reinforced with extra supports under each bearing cage and at the end. Cross- members are also heavy steel joist which form a rectangular main frame of exceptional strength and rigidity. Two heavy roll units, one fixed and one movable are mounted on this frame.

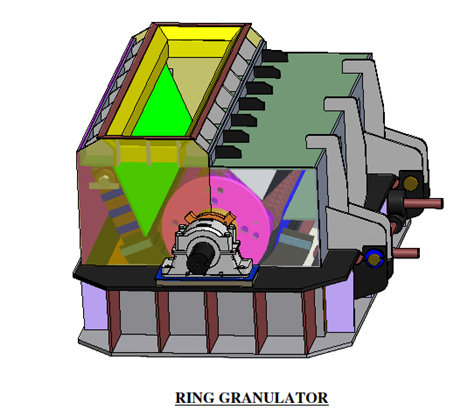

ROLL UNITS

Each roll unit consists of a replaceable manganese steel roll shell, ground V-shaped on the inner periphery. This is mounted on a set of expanding conical rings, which function together as co-acting wedges. These are pulled together by heavy bolts so as to grip manganese shell firmly between them. Both the hubs of co-acting wedges are keyed to a heavy alloy steel shaft mounted on heavy duty self- aligning spherical double row roller bearing. The fixed roll drives the movable roll through a set of star gears. The heavy duty rollers haft bearings are enclosed in a steel bearing housing. The housing for the fixed rolls haft is bolted to the main crusher frame with the housing cage. Movable Rolls haft bearing housing along with slides are fitted in between the slide plates of the main frame and the top slide plates. Slides fitted with each bearing housing are fastened with high tensile counter shanked screws. The movable roll shaft bearing housing is floating and is placed between the gap adjusting shims on one side and spring assembly on the other side. These heavy duty springs assembled with high tensile studs absorb unwanted shocks and thus saves the equipment from damage. This also allows the passage of uncrushable material. Shims between top plate mounting stand and the movable shaft bearing housing fix the distance between rolls and thus determine the discharge opening

ADJUSTMENT

The movable roll assembly is supported by set bolt buffer plates stands and bolts. The other side of the movable roll assembly has provision for inserting adjusting shims. Once these set bolts are released then the adjusting shims can be either added or subtracted. Addition or subtraction of adjusting shims decreases or increases the gap between the rolls. Once the gap is fixed then theses set bolts are once again tightened.