SUMATI SALES CORPORATION

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SUMATI SALES CORPORATION

C.N.C Turning Centres

The CNC SMART TURN turning centre with straight bed maintains the ease of a manual lathe, provides increased productivity and flexibility by replacing mechanical controls with state of the art technology.

Operators using manual lathes can use the SMART TURN system without having any CNC experience.

Electronic handwheels are fitted for operators to handle the machine as on a conventional lathe. Machining is carried out by using a comprehensive choice of automatic cycles selected though the system

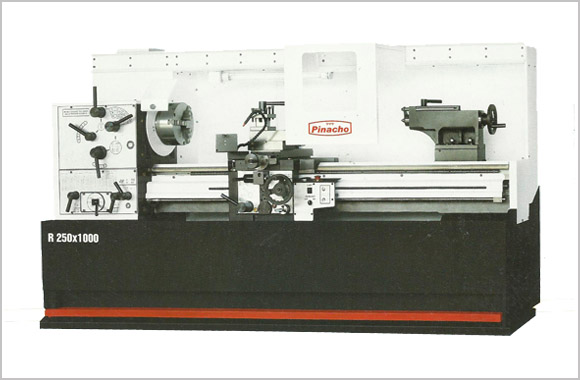

Conventional Lathe

All the gears and shafts of the headstock, feed Box and Apron are made of high quality steel, hardened and ground. Shafts are mounted on needle bearings lubricated oil bath.

A well proportioned headstock enables high working capacity. The headstock is made from GG 25 casting, strongly ribbed, giving, and the machine more rigidity.

The apron is completely enclosed. It is supplied with a safety device which prevents the screw cutting and feed mechanisms acting simultaneously

Milling Machines

Linear Way Machining Centers, Inline Spindle Machining Centers, Twin Table Machining Centers, Solid Way Machining Centers, Horizontal Machines, Bridges and Inline Spindle Bridges, Quill Head Type Bed Mills, Solid Head Type Bed Mills, CNC Knee Mills and Manual Knee Mills. Our milling machines come in a variety of sizes for both large production environments and small tool room needs. Every machine comes standard with our user-friendly high performance Milltronics CNC with conversational programming and loads of features. No other manufacturer compares to Milltronics in quality, value and depth of product options.

Conventional Machine

All lathes utilize a heavy-duty construction of typical “V” ways on our smaller toolroom lathes and manual engine lathes, oversized linear rails on the smaller slant bed lathes with rigid box way construction on the larger slant beds and all combination lathes. All combination lathes incorporate manual operation, handwheel teach and full CNC operation with either conversational or standard ISO programming. Select models are available with a Fanuc or Siemens control as well. Feature for feature, pound for pound, nothing competes with our turning centers.

C.N.C Tools

Description / Specification of C.N.C Tools

We are involved in offering a wide range of C.N.C Tools to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of C.N.C Tools. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Tapping Attachment

REVERSIBLE TAPPING ATTACHMENT WITH ROBUST CONSTRUCTION OFFER FOLLOWING ADVANTAGES:

» Usable on every vertical drilling machine or machines with rotating non-reversing spindles.

Right or left hand tapping without modification.

Complete protection against tap breakage ensured by an ultra-sensitive and smooth operating ball-clutch.

Forward and reverse ball drive design transmits rotational power to the tap and disengages smoothly and silently.

Axial float ensures smooth tapping and better thread profile.

Cushioned drive elimnates the possibility of cross threadings during roughing and finishing taps and ensures gauge prefect thread.

A planetary gear reversing mechanism transmits smooth positive reverse to the tap retraction and it retracts 75% more faster than it enters.

Accurate depth control by means of its accurate neutral mechanism.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.