SUBNIL PACKAING MACHINES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SUBNIL PACKAING MACHINES P.LTD.

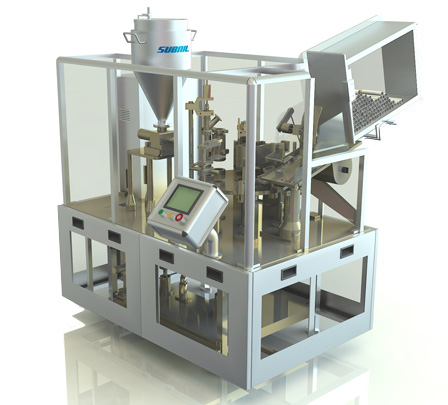

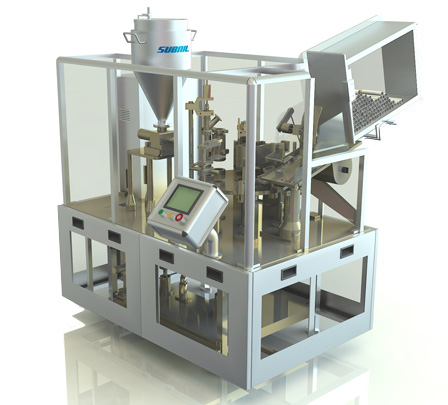

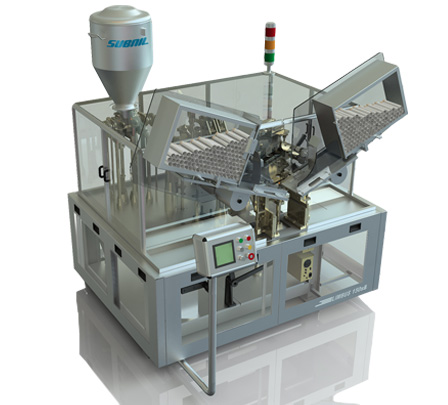

Tube Fillers

The LIMBUS 35 is the smallest tube filler in Subnil’s range with a capacity to produce about 12,000+ tubes per shift,

Tubes have to be first manually transferred from the tube box, into the cassette on the machine. They are then loaded one by one into the holders on the turret. First the tubes are centered & oriented and then filled. They are then closed depending on the type of tube. In case of metal tubes, the tubes are flattened and crimped twice (or even thrice). In case of laminate / plastic tubes, they are first heated on the inside periphery and then sealed. Batch details are then coded on the crimp (or seal) with metal stereos and the tubes are ejected out either into a collection container or to a tube-transfer system to link to the downstream MERLIN 120XC cartoner from Vectacraft.

Technical Specifications

Features

The pump unit has a vertical dosing system, which aids in easy suction

Bottom-up filling coupled with shut-off nozzle ensures accurate & clean fill without air entrapment

Indexer is absolutely smooth.

Tool-less adjustments coupled with faster reproduction of settings (aided by position indicators and tri-clover fittings) make changeover quite effortless.

Product level sensor, centralised lubrication and a host of safety features like detection of reverse tube, jammed tube, air pressure drop etc. are part of basic machine.

Optional equipment

Saddle fold

Multi-colour filling

Designer seal in plastic tubes

Gas flushing before & after filling

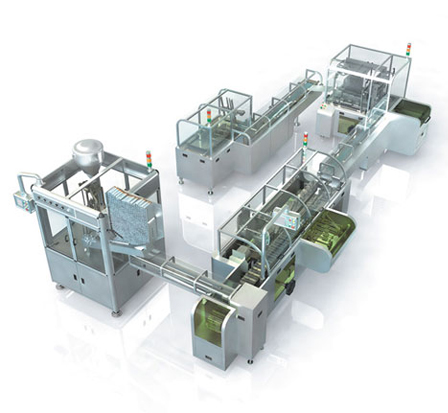

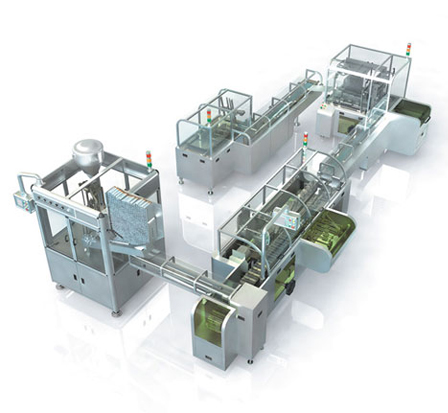

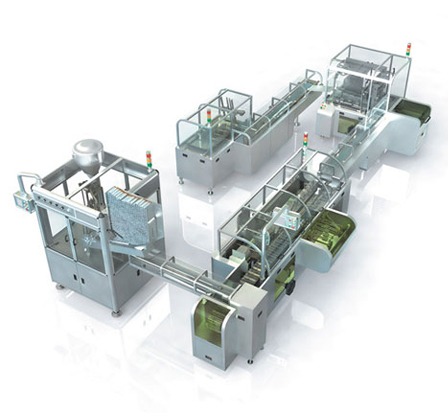

Tube Filling Lines

The SL 70 is a slow/medium speed tube packaging line producing about 23,000 tubes per shift. The LIMBUS 70 is a mid-range single-head tube filler which fills the product into the tube and then closes it depending on the type of tube. Metal tubes are crimped whereas plastic/laminate tubes are sealed.

Once closed, the tube is ejected out of the tube filler onto a tube transfer system which flaps the tube exactly into the pocket of the product conveyor of the MERLIN 120XC horizontal cartoner. Here, first a pre-folded leaflet is picked up by a rotary pick-up device and fed to the pincer on the leaflet chain. Then, a carton is picked up from the stack by a rotary pick-up device, pre-broken and then loaded into the carton chain. The tube is inserted into the carton and it is closed on both sides either by tuck-in or gluing.

The cartons then travel from the outlet of the cartoner to the in-feed conveyor of the OSPREY 18V bundler where they are first collated in a desired matrix. The required length of BOPP film is then brought down by grippers; the bunch is wrapped with the same and pushed to the sealing station. Here, first the main overlapped film is sealed and subsequently the films on the pack ends are sealed to create a sturdy multipack.

The multipacks then travel to one of the KESTREL series casepackers where they are collated in a required configuration and then pushed into a case, which has been opened and kept ready earlier. The case is then taped or glue-sealed.

Hence, the first machine takes in the empty tubes and the product to be filled and the last machine produces a packed case, ready to be shipped out of the customer’s factory.

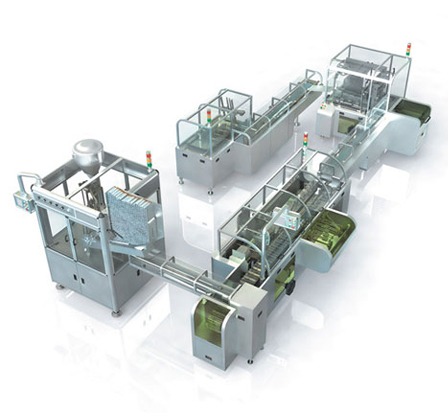

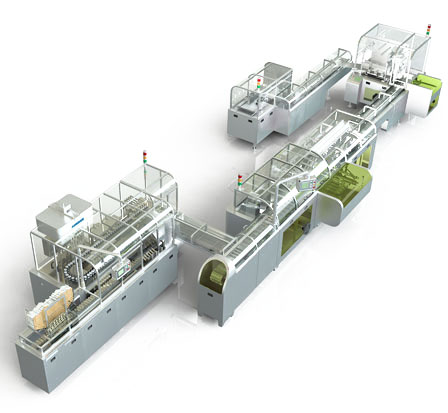

Medium Speed Tube Packaging Line

The SL 100 is a medium speed tube packaging line producing about 33,000 tubes per shift. The LIMBUS 100 is the fastest single-head tube filler in Subnil’s range. It fills product into the tube and then closes it depending on the type of tube. Metal tubes are crimped whereas plastic/laminate tubes are sealed.

Once closed, the tube is ejected out of the tube filler onto a tube transfer system which flaps the tube exactly into the pocket of the product conveyor of the MERLIN 120XC horizontal cartoner. Here, first a pre-folded leaflet is picked up by a rotary pick-up device and fed to the pincer on the leaflet chain. Then, a carton is picked up from the stack by a rotary pick-up device, pre-broken and then loaded into the carton chain. The tube is inserted into the carton and it is closed on both sides either by tuck-in or gluing.

The cartons then travel from the outlet of the cartoner to the in-feed conveyor of the OSPREY 18V bundler where they are first collated in a desired matrix. The required length of BOPP film is then brought down by grippers; the bunch is wrapped with the same and pushed to the sealing station. Here, first the main overlapped film is sealed and subsequently the films on the pack ends are sealed to create a sturdy multipack.

The multipacks then travel to one of the KESTREL series casepackers where they are collated in a required configuration and then pushed into a case, which has been opened and kept ready earlier. The case is then taped or glue-sealed.

Hence, the first machine takes in the empty tubes and the product to be filled and the last machine produces a packed case, ready to be shipped out of the customer’s factory.

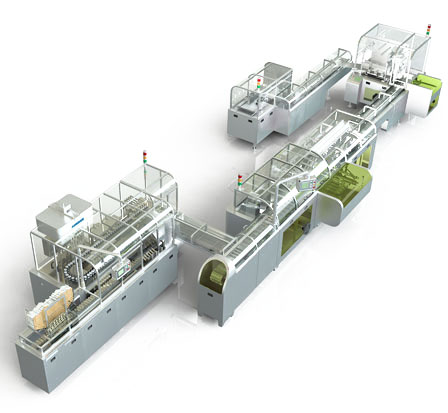

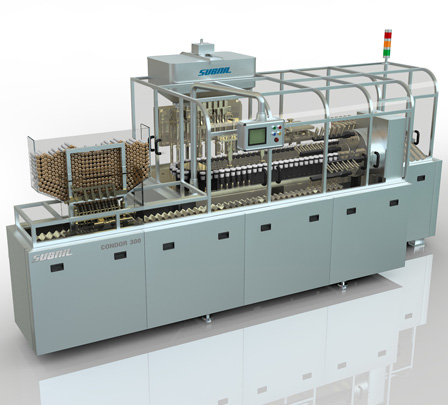

Plastic Tubes Filling Machines

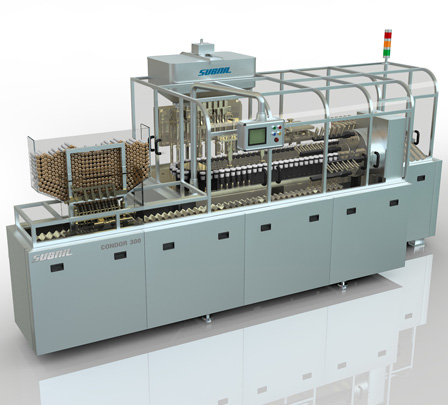

The SL 300 is the fastest tube packaging line in Subnil’s stable. With a capacity to produce about a whopping 100,000 tubes per shift, the line starts with the CONDOR 300 linear-model tube filler. It’s a 4-head tube filler which fills product into the tube and then closes it depending on the type of tube. Metal tubes are crimped whereas plastic/laminate tubes are sealed.

Once closed, the tube is ejected out of the tube filler onto a 4-lane tube transfer system which flaps the tube exactly into the pocket of the product conveyor of the MERLIN 300XC horizontal cartoner. Here, first a pre-folded leaflet is picked up by a rotary pick-up device and fed to the pincer on the leaflet chain. Then, a carton is picked up from the stack by a 3-arm rotary pick-up device, pre-broken and then loaded into the carton chain. The tube is inserted into the carton and it is closed on both sides either by tuck-in or gluing.

The cartons then travel from the outlet of the cartoner to the in-feed conveyor of either the OSPREY 18V or 30V bundler (depending on the matrix), where they are first collated as desired. The required length of BOPP film is then brought down by grippers; the bunch is wrapped with the same and pushed to the sealing station. Here, first the main overlapped film is sealed and subsequently the films on the pack ends are sealed to create a sturdy multipack.

The multipacks then travel to one of the KESTREL series casepackers where they are collated in a required configuration and then pushed into a case, which has been opened and kept ready earlier. The case is then taped or glue-sealed.

Hence, the first machine takes in the empty tubes and the product to be filled and the last machine produces a packed case, ready to be shipped out of the customer’s factory.

Laminate Tubes Filling Machiones

The CONDOR 300 is a high-speed tube filler with a capacity to produce about 100,000 tubes per shift. This is the fastest tube filler in Subnil’s range.

The tubes have to be first manually transferred from the tube box to the cassette provided on the machine. In turn the cassette transfers them, through multiple chutes, to a servo-driven pocketed conveyor. From the conveyor, multiple tubes are picked up by a rotary pick-up device, driven by servo, and loaded into the tube holders. First the tubes are centered & oriented and then filled. They are then closed depending on the type of tube. In case of metal tubes, the tubes are flattened and crimped twice (or even thrice). In case of laminate / plastic tubes, they are first heated on the inside periphery and then sealed. Batch details are then coded on the crimp (or seal) with metal stereos and the tubes are ejected out either into a collection container or to a tube-transfer system to link to the downstream MERLIN 300XCcartoner from Vectacraft.

Technical Specifications

Features

The pump unit has a vertical dosing system, which aids in easy suction

Bottom-up filling coupled with shut-off nozzle ensures accurate & clean fill without air entrapment

Indexer is absolutely smooth.

Tool-less adjustments coupled with faster reproduction of settings (aided by position indicators and tri-clover fittings) make changeover quite effortless.

Product level sensor, centralised lubrication and a host of safety features like detection of reverse tube, jammed tube, air pressure drop etc. are part of basic machine.

Optional equipment

Saddle fold

Multi-colour filling

Designer seal in plastic tubes

Gas flushing before & after filling

Servo motor options in various stations

Metal Tubes Filing Machines

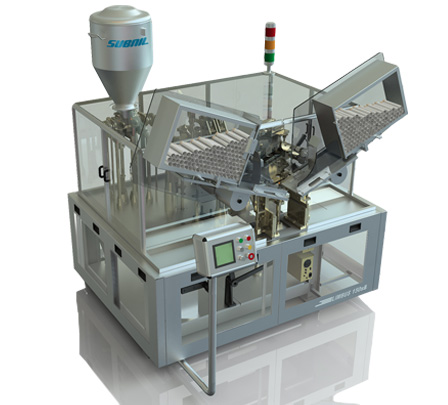

The LIMBUS 150 is a twin-head medium/fast speed tube filler able to produce about 45,000+ tubes per shift

Tubes have to be first manually transferred from the tube box, into the two cassettes on the machine. They are then loaded one by one into the holders on the turret. First the tubes are centered & oriented and then filled. They are then closed depending on the type of tube. In case of metal tubes, the tubes are flattened and crimped twice (or even thrice). In case of laminate / plastic tubes, they are first heated on the inside periphery and then sealed. Batch details are then coded on the crimp (or seal) with metal stereos and the tubes are ejected out either into a collection container or to a tube-transfer system to link to the downstream MERLIN 180XC cartoner from Vectacraft.

Technical Specifications

Features

The pump unit has a vertical dosing system, which aids in easy suction

Bottom-up filling coupled with shut-off nozzle ensures accurate & clean fill without air entrapment

Indexer is absolutely smooth.

Tool-less adjustments coupled with faster reproduction of settings (aided by position indicators and tri-clover fittings) make changeover quite effortless.

Product level sensor, centralised lubrication and a host of safety features like detection of reverse tube, jammed tube, air pressure drop etc. are part of basic machine.

Optional equipment

Saddle fold

Multi-colour filling

Designer seal in plastic tubes

Gas flushing before & after filling

Servo motor options in various stations

Tube Packaging Lines

The SL35 is the smallest tube packaging line in Subnil’s range, consisting of tube filler and cartoner only. With a capacity to produce about 12,000+ tubes per shift, the LIMBUS 35 tube filler fills the product into the tube and then closes it depending on the type of tube. Metal tubes are crimped whereas plastic/laminate tubes are sealed.

Once closed, the tube is ejected out of the tube filler onto a tube transfer system which puts the tube into a vertically positioned carton which is kept ready in open position in the HARRIER vertical cartoner. Prior to this, in the HARRIER, a pre-broken carton is picked up from the stack by a swing-arm and then loaded into a turret which has slots as per the carton size, on its periphery.

Once the carton is loaded into the turret, first the bottom flap of the carton is closed either by tuck-in or gluing, as the case maybe. Then the product is inserted as above. Printing is done on the flap of the carton by debossing or inking and the top flap is then closed. Finally the carton is ejected out in a vertical position which can then be oriented depending on further processes.

Being a low-volume line, a bundler or a casepacker might not prove economical and hence we have not made a model especially for this. However, if needed, we can supply the same from our current range of these two machines.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.