STERDILL EQUIPMENTS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to STERDILL EQUIPMENTS P.LTD.

Steam Water Spray Retort

Today's markets continuously demand new packaging materials for the presentation of shelf stable foodstuffs. Custom tailored solutions, convincing with regard to economics, performance and quality, are more important than ever. Based on more than 100 years of experience and a steady, innovative development of automated systems, STOCK offers individually designed solutions to customers. First-class references around the globe rely on this proven Technology.

Now STOCK Retorts are manufactured in India by STERDILL with technical Know-how from Germany.

Full Water Immersion Retort

Today's markets continuously demand new packaging materials for the presentation of shelf stable foodstuffs. Custom tailored solutions, convincing with regard to economics, performance and quality, are more important than ever. Based on more than 100 years of experience and a steady, innovative development of automated systems, STOCK offers individually designed solutions to customers. First-class references around the globe rely on this proven Technology.

Now STOCK Retorts are manufactured in India by STERDILL with technical Know-how from Germany.

R And D Retort

Retort series for research and development :

The retort series Pilot Rotor is the most qualified equipment suitable for all kinds of scientific studies on the subject of thermal processing and practical industrial research. For production tests of all kinds, especially for the development and testing of new products. Particularly suitable for assessing new packaging materials and new types of food containers as well as testing their behavior during heat treatment, in order to design optimal processing guidelines for future products Moreever, it is possible to establish basic facts and decisive data for new recipes in order to obtain market conforming and high quality products. Indispensable for scientific institutes, food technology schools and development laboratories in the food industries. Ideal for processing small production quantities predetermined for market tests.

Perforated Mats Moulded Profile

Description / Specification of Perforated Mats Moulded Profile

We are involved in offering a wide range of Perforated Mats Moulded Profile to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Perforated Mats Moulded Profile. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Moulded Plastic Trays

Description / Specification of Moulded Plastic Trays

We are involved in offering a wide range of Moulded Plastic Trays to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Moulded Plastic Trays. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Stainless Wire Trays

Description / Specification of Stainless Wire Trays

We are involved in offering a wide range of Stainless Wire Trays to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Stainless Wire Trays. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Stainless Plate Trays

Description / Specification of Stainless Plate Trays

We are involved in offering a wide range of Stainless Plate Trays to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Stainless Plate Trays. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

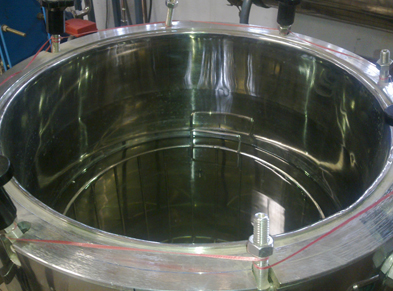

Hot Water Bath

The equipment will have Chamber Diameter 500 & 900mm triple chamber construction, i.e. the inner chamber will be made of 304 quality stainless steel sheets and the jacket will be made of AISI 304 quality stainless steel sheets, duly argon arc welded.

The jacket will be insulated with glasswool and covered with polished 304 quality stainless steel sheets to minimize heat loss.

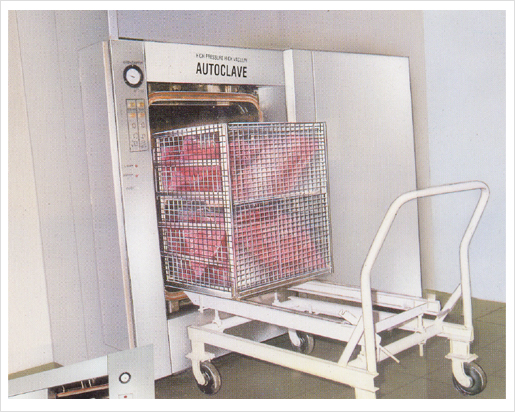

Steam Sterilizer Autoclave

USES:

Fabwell Sterilizers are ideal for Hospitals, Research Laboratory and other Pharmaceutical Industry.

They are designed for safe & efficient sterilization of various items such as Ampoules & Vials, Rubber goods, empty flasks, instruments & utensils, Fabrics wrapped or unwrapped, etc.

CONSTRUCTION:

The chamber is constructed of heavy duty stainless steel 316 to with stand pressure of 2.2 Kg/cm2 corresponding to temperature of 1340C and also to with stand vacuum of 650-700 mm (26"/28") of Hg. in Chamber.

Two rails are provided in the chamber bottom for easy loading & unloading of the material on Carriage.

DOORS:

The Sterilizer is supplied with single door or double doors made of 304/316 S .S. The doors are having automatic sliding type arrangement OR Manual Hinge type doors.

The doors will have unique arrangement to open them manually in case of power failure.

The door Gasket will be of Silicon Rubber.

Superheated Water Shower Sterilizer

USES :

Fabwell counter pressure sterilizers are ideal for Pharmaceutical Companies, Laboratories, & Food Processing Industries, etc. They are designed for safe & efficient sterilization of various items such as Solutions in closed containers viz. ampoules, vial, glass bottles, PVC bottles, PE bottles, PP bottles, IV Bags, Semi-open containers, Blister Packing, Contact Lenses etc.

STERILIZER ARE DESIGNED IN TWO DIFFERENT TYPES :

"SWS" type where treatment is carried out with forced Superheated Water circulation with spray distribution system

CONSTRUCTION :

The chamber is of round cross-section constructed of heavy duty stainless steel 316L/316Ti to withstand pressure of 3 Kg/em. It is insulated with

Two rails are provided in the chamber bottom for easy loading & unloading of the material on Carriage.

The Sterilizer is supplied with single door or double doors made of 304/316 S.5. The doors are either manually operated Hinged type or having automatic electromechanical type sliding arrangement.

The Unit along with various accessories & piping is supported with Frame designed for proper load distribution on floor.

Air Steam Sterilizer

USES :

This counter pressure sterilizers are ideal for Pharmaceutical Companies, Laboratories, & Food Processing Industries, etc. They are designed for safe & efficient sterilization of various items such as Solutions in closed containers viz. ampoules, vial, glass bottles, PVC bottles, Syringes, Tubes, PE bottles, PP bottles, IV Bags, Semi-open containers, Blister Packing, Contact Lenses etc. & also for Pasteurization of products like Blood plasma.

"SAS" type where treatment is carried out Steam & Air mixture with supporting circulation fan.

Dry Heat Sterilizer

USES :

Fabwell Dry Heat Sterilizers-Depyrogenation units are ideal for Pharmaceutical and Allied Industries, Laboratories, Research Institutes, Food Industries, etc.

They are designed for safe & efficient sterilization- Depyroganation of Ampoules & Vials, Rubber Stoppers, Medical Powder, Tablets, Granule drying etc.

CONSTRUCTION :

The Sterilizer is normally suitable to operate in temperature range of 160°C-180°C to 250°C/270°C.

The chamber is constructed for stainless steel 316 is having taper to achieve proper air circulation in sterilizer.

All inside contact parts are of stainless steel.

The chamber has Glass Wool insulation & it is covered with Stainless Steel Outer Cover.

This will reduce external unit temperature.

Pure Steam Generator

Fabwell Pure Steam Generator used in the Pharmaceutical Industry & Hospitals for Sterilization of

certain Items such as fermenters, Filters, whenever any item that comes into direct contact with a sterile medicinal product is sterilized, Sterilization of Various Articles used in critical surgeries etc.

Artwork is in same Size: 8.5" x 11"

Water Distilling Unit

MULTIPLE EFFECT STILLS :

To produce water which meets various international pharmacopeias & IP/BP standards.

OPERATION :

Fabwell unit works on two main principles a falling film type heat exchanger & Effective re-use of heat energy by Multi-Stage operation.

Feed water enters the still at the condenser. As it flows through the condenser tubing, it transfers the heat from pure steam & distillate. This ensures that feed water enters the further columns at a higher temperature for greater efficiency, and distillate exits the system at a lower temperature for greater safety. The feed water then enters the first column where it is converted into pure steam where all pyrogens are separated with centrifugal movement. This steam enters the shell side of second column condensed by the feed water in the tube side. The steam from second column enters the third column and the process continues for remaining effects.

Steam Sterilizer

USES :

Fabwell Sterilizers are suitable for Hospitals, clinics, Laboratory etc. They are designed for safe & efficient sterilization of various items such as wrapped or unwrapped goods, instruments & utensils etc ..

CONSTRUCTION :

The sterilizer has double walled (inner chamber & Jacket) type design, which allows preheating of chamber by jacket steam.

The chamber is constructed of heavy-duty stainless steel 304/316.

DOORS :

The Sterilizer is supplied with single door or double doors made of 304/316 S .S. The door has provision, which prevents. opening of door when the chamber is under pressure.

Fittings

Washer Di Infector

|

INSTRUMENT WASHER / DISINFECTOR It is fitted with revolving sprays, driven by a water pump. It is operated with circulating water for washing and disinfection. The process includes-prewashing with cold water, detergent wash, hot water rinse (disinfection) at 85o C. The process is automatically controlled in a time regulated sequence bt a programme card; and there is also provision for Manual Operation. The unit is of stainless steel construction having single OR two doors, suitable for electric OR steam heating. Overall Size : 800mm x 800mm x 1500mm H. |

Cssd Planning And Execution

Complete Planning ,Supply & Execution for Hospital of Central Sterilization Supply Department ( CSSD ) & Theatre Sterile Supply Unit (TSSU) supply of Sterilizers, Washers alongwith various units such as..

Ultrasonic Cleaner

Drying Cabinets

Work table

Various trolleys & baskets

Work table with Sink

Storage Racks

Packing Table

Pass Boxes of Stainless Steel to exchange material between Clean & Unclean area, with or without HEPA filter etc

Waste Autoclave

STERILIZATION PROCESS :

The sterilization of biomedical waste is done with the help of saturated steam at the temperature of 121°C/ 134°C.

The sterilizer is operated by steam supplied from the central boiler or by in -built electric steam generator.

HPHV process ensures good penetration of the steam & reduces the cycle time by evacuating air by vacuum pump.

Optional automatic control unit to control & indicate pressure, temperature & time during the the process.

The loading & unloading carriage is made of stainless steel and it is designed to slide easily from chamber to trolley.The floor trolley is

made of M.S. (Painted).

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.