SRS PUMPS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SRS PUMPS

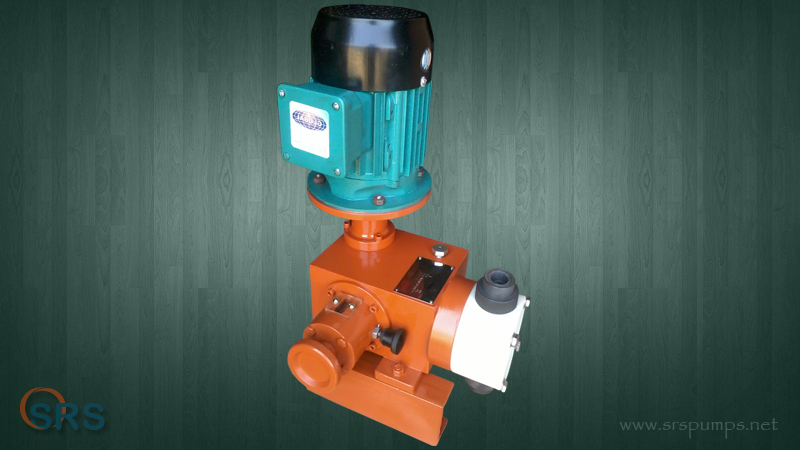

Stainless Steel Plunger Pump

Description / Specification of Stainless Steel Plunger Pump

We are involved in offering a wide range of Stainless Steel Plunger Pump to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Stainless Steel Plunger Pump. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

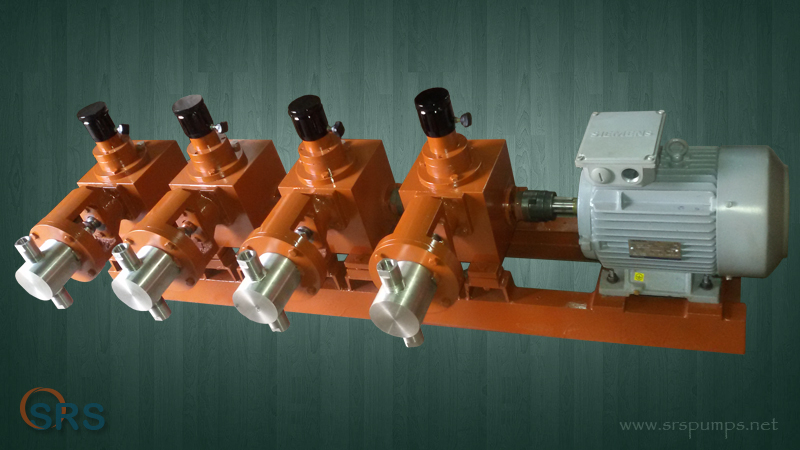

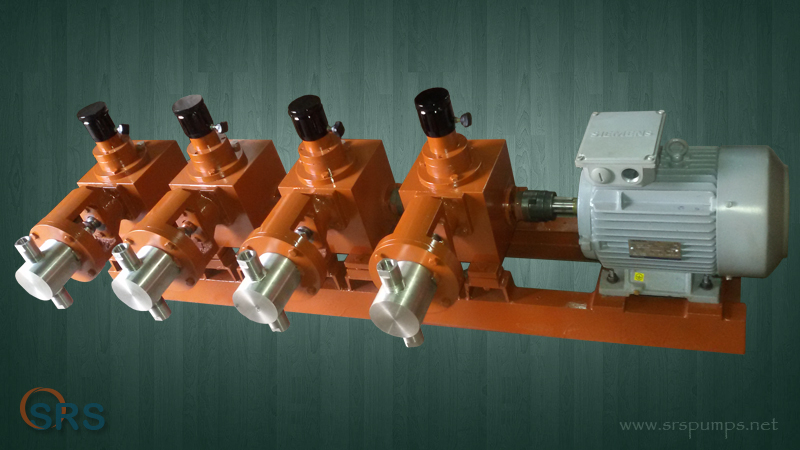

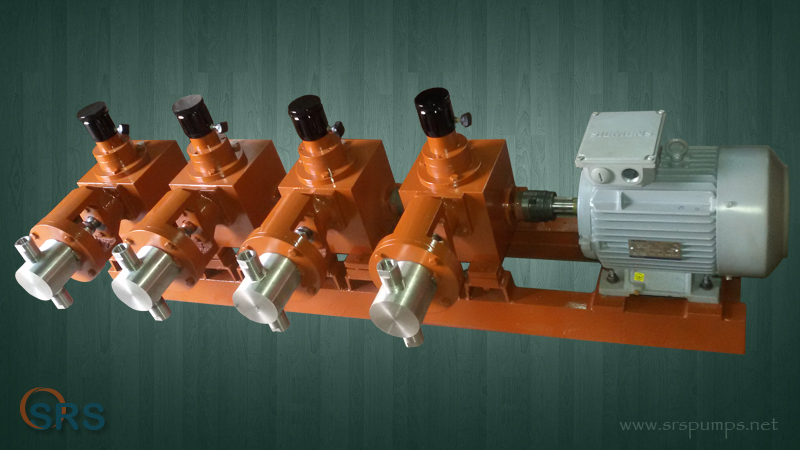

Multiplex Plunger Pump

Description / Specification of Multiplex Plunger Pump

We are involved in offering a wide range of Multiplex Plunger Pump to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Multiplex Plunger Pump. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

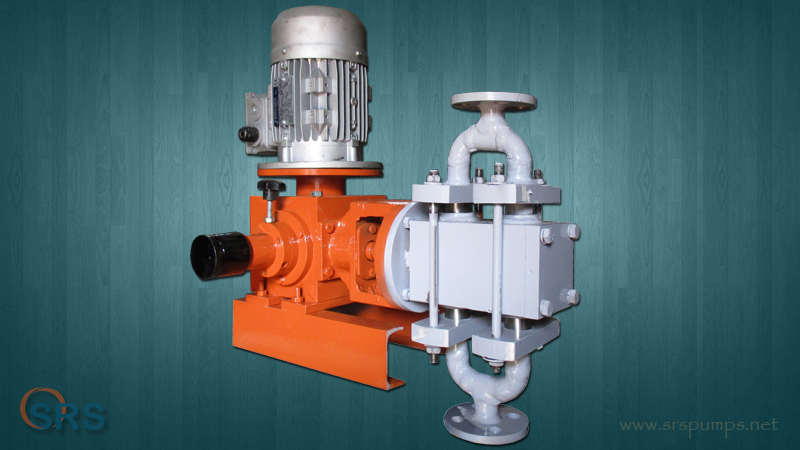

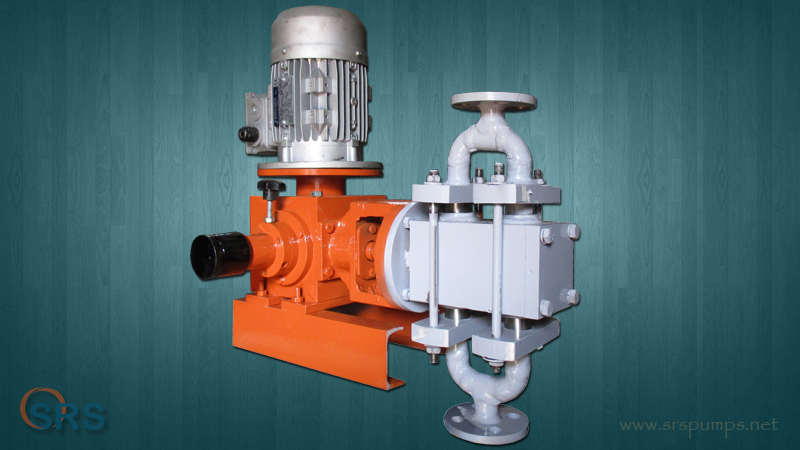

Double Acting Plunger Pumps

Double acting plunger pump is plunger type dosing pump which the working fluid acts alternately on both sides of the piston. This is one that, as it fills one end of the liquid chamber, is discharging liquid from the other end of the chamber. On the return stroke, the end of the chamber just emptied is filled, and end just filled is emptied.

Each stroke of the piston fills one chamber and empties another, which nearly doubles the flow rate over a single-acting plunger pump. It also smooth in the flow and the basic principal of operation will be identical. This pump can be used for high precision injections with pulse rates of ±1%.

Have you ever seen a pulseless metering pump? You’ve never actually seen a pulseless metering pump, even though you may have seen similar pumps. You might have seen a pulse reduction pump, which reduces the pulse with pump piping or a built-in air chamber. However, SRS Pumps has successfully developed actual pulse-less pump technology. In the belief that we coexist with our customers, we will show you true essence of Pulseless Pump.

Features

- Accurate & sophisticated dosing metering.

- Fixed & variable output choice.

- Leak proof in nature.

- Compact, sturdy design & long lasting.

- Low power consumption.

- High efficiency.

- Noiseless running.

- Virtually maintenance free.

- In built versatility to suit any kind of liquids.

- Abrasion resistant and corrosion resistant.

- Pump performance confirms API 675 international standard.

- Value for money.

Hydraulic Diaphragm Pump

In hydraulic pump the process liquid is isolated from plunger by hydraulic oil and a diaphragm. Normally Teflon is used as a diaphragm material due to its flexibility and corrosion resistivity.

Hydraulic diaphragm pumps are recommended for the applications where the leakage is not at all permitted. It provides an integral safety valve which can automatically protect the diaphragm while the fluctuation in the line.

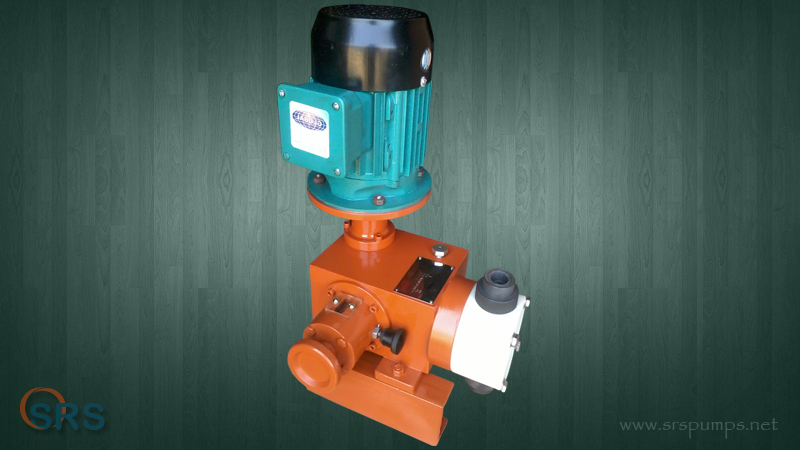

Electromagnetic Diaphragm Pump

We, SRS Pumps are reputed manufacturers and suppliers of Dosing Pumps, Metering Pumps, Electromechanical Dosing Pumps, and Industrial Metering Pumps. These pumps are used where fluids must be dosed into a medium with a highest possible grade of accuracy with a defined volume and within a defined time period.

The electro magnetic metering pumps are used in low pressure and low flow applications. The drive unit consumes less energy than motor driven pumps. The pump capacity is varied by both stroke length and speed controls.

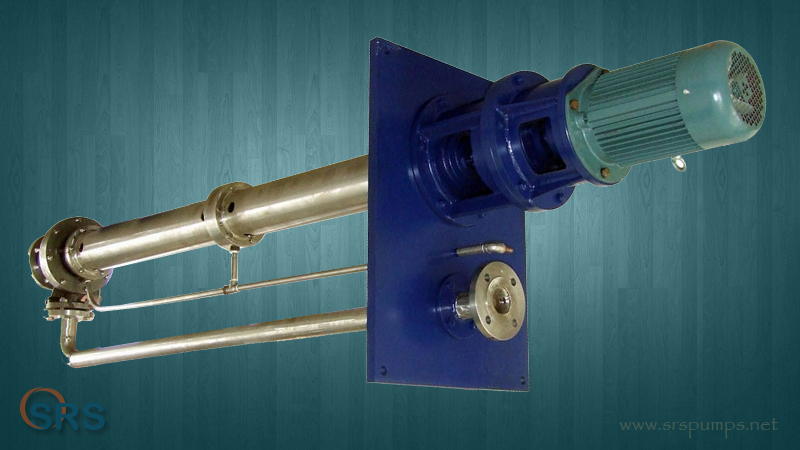

Vertical Sump Pump

We design and manufacture the industrial sump pumps to handle various type of fluids from drainage water or any liquid waste containing non-fibrous solids to larger industrial processes.

This model is available in various types of materials and configurations for various types of industries. It can be configured for suspension plate or self supporting stand. These sump and condensate application pumps are available with high thrust bearing for temperatures over 200 degrees Fahrenheit. These pumps are available in 1.5 inches to 8 inches discharge sizes and flow rate upto 1600 GPM.

Features

- Adjustable impeller,

- Leak proof,

- Vapor tight construction,

- Extensions for pit depths from 2 to 20 feet.

Applications

- Sump drainage,

- Industrial process,

- Elevator pits,

- Basements,

- Power plants,

- Flood control,

- Storm water,

- Condensation control,

- General dewatering service.

Specifications

- Pump: A centrifugal type pump fitted with a semi-open impeller accurately machined and balanced for smooth, quiet operation.

- Mechanical Shaft Seal: Sump pumps are fitted with a mechanical shaft seal which prevents the liquid being pumped from entering the lower sleeve bearing while retaining the lubrication in the pump.

- Pump Lubrication: Lubrication system provides continuous lubrication to shaft, self lubricated intermediate and lower sleeve bearings. It eliminates the external grease lines.

- Shaft Column Pipe: Shaft column pipe is manufactured with schedule 80 hot dipped galvanized steel as per the standard.

- Shaft: Size 1 inch high accuracy, grade 1215 that is turned, ground and polished. Shafts are also available in stainless steel.

- Discharge Pipe: The discharge pipe is manufactured with schedule 40 hot dipped galvanized steel as per the standard.

- Motor Support Bracket: The heavy cast pedestal is accurately machined to house the thrust bearing and align the motor.

- Thrust Bearing: The thrust ball bearing is grease lubricated and elevated above the cover plate for protection from dirt and moisture.

- Floor Plate Suspension Cover: Heavy duty steel is used in floor plate and we will fabricate covers to duplicate existing pumps and piping.

- Motors: The motor and pump shafts are connected by a flexible coupling that allows the motor to be easily removed without distributing the pump and piping.

- Strainer: The strainer of the industrial sump pumps are made of heavy cast iron construction as per standard.

- Float Control: Heavy duty pedestal mounted float switch and stainless steel float ball is used as float control.

- Basin Cover: Heavy duty basin cover capable of supporting vertical suspended pumps and motors. Covers are available for simplex, duplex or other configurations.

High Pressure Pump

High pressure pumps are designed and manufactured by SRS Pumps with Advanced Pump Technology which ensure quality, reliability and efficiency. Our high pressure pumps are Horizontal, simplex or Triplex positive displacement plunger pumps.

Our High Pressure Equipments is the most versatile, time-and-cost effective solution for Cleaning, Cutting, Removing, Descaling, Testing, Spraying etc.

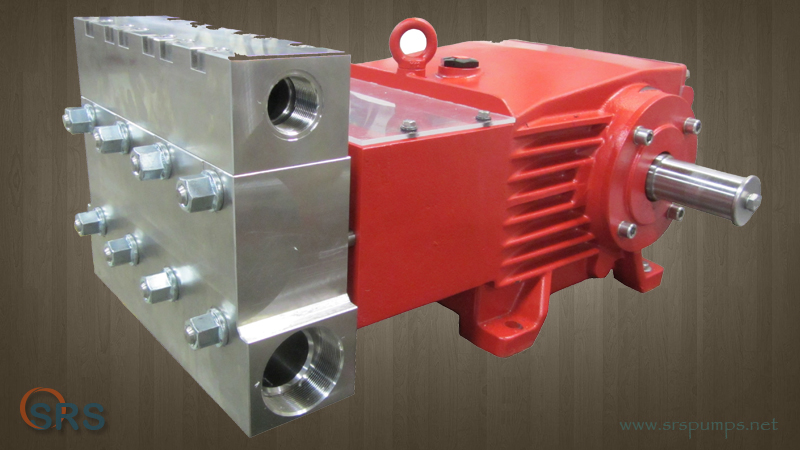

High Pressure Plunger Pump

Description / Specification of High Pressure Plunger Pump

We are involved in offering a wide range of High Pressure Plunger Pump to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of High Pressure Plunger Pump. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

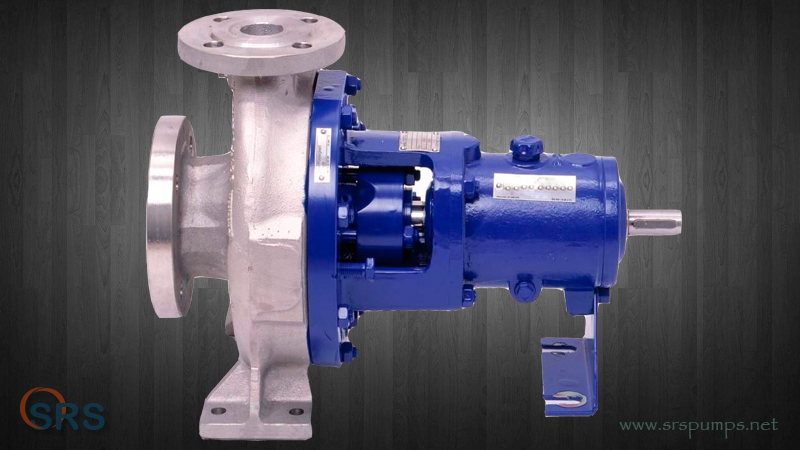

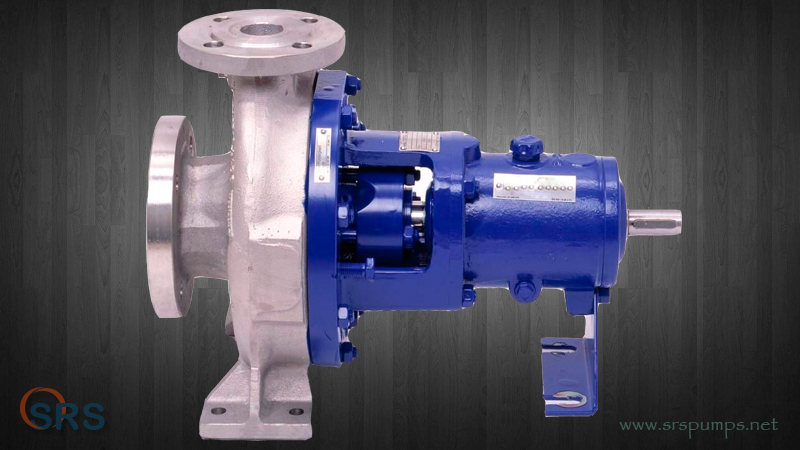

Back Pullout Type Centrifugal Pump

Description / Specification of Back Pullout Type Centrifugal Pump

We are involved in offering a wide range of Back Pullout Type Centrifugal Pump to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Back Pullout Type Centrifugal Pump. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Centrifugal Pump

SRS Pumps is a manufacturer of domestic and industrial dosing pumps. It offers centrifugal pumps and mono-block centrifugal pumps with the following specifications...

- Capacity range : up to 80 mtr3/hr

- Head range : up to 60 mtrs

- Electrical motor : 0.5 to 25 HP

- Sealing arrangement : gland/mechanical seal

- Materials of construction : all pumps are cast iron, i.e., pump casing, impeller, gland cover, bearing cover, bearing housing.

However these pumps can also be supplied in different materials of construction like bronze impeller/SS, all parts in SS, etc.

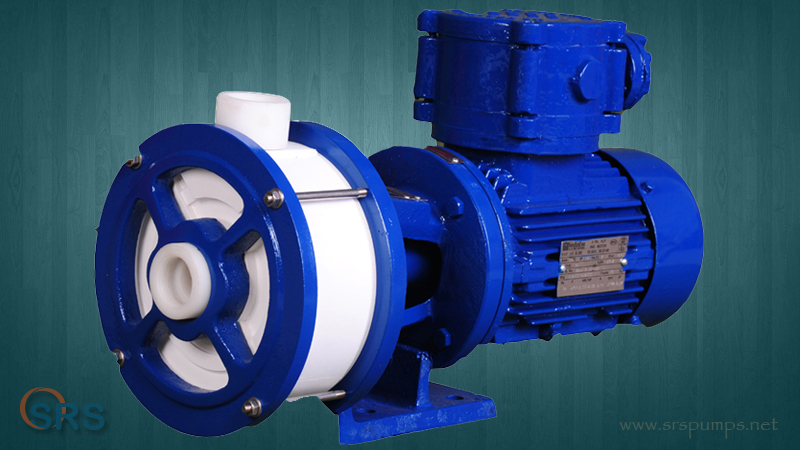

Non Metallic Transfer Pump

SRS Pumps specializes in the application engineering of process pumps and utility pumps for use in various industries. We markets a full range of non-metallic process pumps for handling acids, alkalies, solvents, petro-products, treated water etc.

Acid Regeneration Plants, Effluent Treatment Plants, Power Generation Plants, Pharmaceutical Plants, Rerolling mills, Chemical Industry, Pulp & Paper Industry, Picture Tube Industry, Dyes & Intermediates Industry, Paint Industry, Sugar Mills, Alkalies & Caustic Soda Plants, etc. are the sites where these pumps are most required.

These pumps are made up of materials like polypropylene, glass filled polypropylene, polyvinylidene fluoride (PVDF) and CF - 8M (SS - 316), cast steel, high nickel Alloys, Hastalloy etc. These are corrosion resistant pumps and are mostly used in chemical and process industries where due to higher delivery heads, the effects of erosion owing to the higher liquid velocities, are multiplied. These products are relied upon by a wide spectre of industrial units for toughest pumping applications.

Chemical Dosing System

SRS Pumps do design, manufacture and install the chemical dosing systems for petrochemical applications and water treatment plants.

The chemical dosing systems where totally customized to fit customer's requirements and to ensure the maximum efficiency in chemical dosing required by the process for the specific application.

We follow the international quality standards. We provide the skid mounted chemical dosing systems with qualitative range. Our quality engineers check each and every component according to the required quality specifications. We conduct trail process before shifting the chemical dosing system to the customers’s location. All the components are calculated as per the discharge pressure of the skid mounted dosing systems for safety precautions of the System. We can also supply the chemical dosing systems for following applications...

- Chlorine dosing system,

- Boiler chemical dosing system,

- Oil heating system,

- Additive Injection System,

- Slurry dosing system,

- Alcholic Dosing System,

- Blue dye injection system,

- Perfural dosing system,

- Marker dosing system,

- Bio-diesel blending system,

- PH Level control dosing system,

- Pumping units and other such duties.

Dosing system are designed to meet the need for accurate and precise dosages for chemical and water treatment plants.

It uses the best vailable metering pumps which may have a higher price than that of a competitor, but the true cost of owning a these pumps must take into account with the life expectancy of the entire system and its key components, the frequency of repairs, the cost of repairs and downtime, the cost of labor, and the energy consumption of the system, the spares to be maintained.

The diaphragm is made of high quality raw-materials. The body is made of SS, PVC or polypropylene, suitable for most chemical and water treatment applications. Other materials such as acrylic and teflon can be provided depending on the liquid to be dosed.

The Chemical Dosing System consists of a solution tank, pumps and accessories. Please contact us for more information about the chemical dosing systems.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.