Products & Services

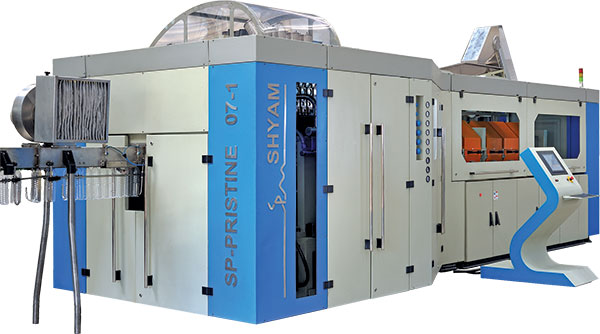

Automatic Pet Blow Moulding Machine

Preform Handling

Loading on Oven Mandrels using Turret Wheel System.

Heat Conditioning

Close Loop Heating Control (Auto Preform Temperature Control).

Variable speed ventilators for accurate Chamber Temperature Control.

Modular Heating System for quick maintenance of Heating Lamps.

Replica jig for Simpler, Faster and Accurate positioning of Heating Lamps.

Stretching

Servo Stretching in Dual mode in synchronization with Mould Clamp, to reduce cycle time.

Precise control of Preblow (Primary Blow) and Blowing (Final Blow).

Reduced Frictional and Inertia loss.

Mould Clamp

Electrical Mould Clamp using servo system.

Mould Compensation for faster and positive locking without vibration.

Synchronized with Stretching functions.

Energy Saving

No Low Pressure Air required. Blowing air is recovered and re-collected to be used for machine operations, fed back to booster compressor.

Heating lamps adjustable to go closest to perform, to reduce attenuation loss.

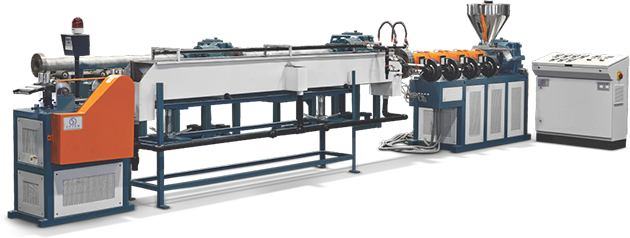

Pet Stretch Blow Moulding Machine

Preform Handling

Loading on Oven Mandrels using Turret Wheel System.

Heat Conditioning

Close Loop Heating Control (Auto Preform Temperature Control).

Variable speed ventilators for accurate Chamber Temperature Control.

Modular Heating System for quick maintenance of Heating Lamps.

Replica jig for Simpler, Faster and Accurate positioning of Heating Lamps.

Stretching

Servo Stretching in Dual mode in synchronization with Mould Clamp, to reduce cycle time.

Precise control of Preblow (Primary Blow) and Blowing (Final Blow).

Reduced Frictional and Inertia loss.

Mould Clamp

Electrical Mould Clamp using servo system.

Mould Compensation for faster and positive locking without vibration.

Synchronized with Stretching functions.

Energy Saving

No Low Pressure Air required. Blowing air is recovered and re-collected to be used for machine operations, fed back to booster compressor.

Heating lamps adjustable to go closest to perform, to reduce attenuation loss.

Semi Automatic Pet Blow Moulding Machine

Mould Clamping

- Hydraulic mould clamping system to enhance power efficiency. It saves air consumption and hence reduces production cost.

- Unique mechanical lock system for positive locking.

Heating

- Close loop heating system and auto chamber temperature control (to compensate variation in preform heating due to ambient temperature).

- Optional auto preform temperature control.

- Positioning of heaters is better, ensuring faster and simpler heating. Individual heater position is adjustable in both axes to achieve optimum heating.

- Air ventilation with controllable venting in heating chamber (for better heat penetration control).

- Start-stop index type oven to minimize variation in temperature of both preforms coming out of chamber at a time.

Product Range

- Versatile range to produce 40 ml to 5000 ml bottle / jar. Neck diameter ranging from 20 mm to 120 mm. Due to hydraulic operations, mould can be stopped where required. In case of small diameter bottles, this increases production rate and reduces production cost.

Safety

- Two hand operations (till mould close function is complete) to prevent accidents.

- ELCB in main supply for protection against electric shock.

- Individual MCBs for all heaters.

Bubble Top Blow Moulding Machine

Mould Clamping

Hydraulic mould clamping system to enhance power efficiency. It saves air consumption and hence reduces production cost.

Unique mechanical lock with mould compensation system.

Heating

Auto-controlled air ventilation in heating chamber for better heat penetration and to minimise ΔT in heating chamber.

Safety

Two hand operations (till mould close function is complete) to prevent accidents.

ELCB in main supply for protection against electric shock.

Individual MCBs for all heaters.