SURESH INDU LASERS P. LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SURESH INDU LASERS P. LTD.

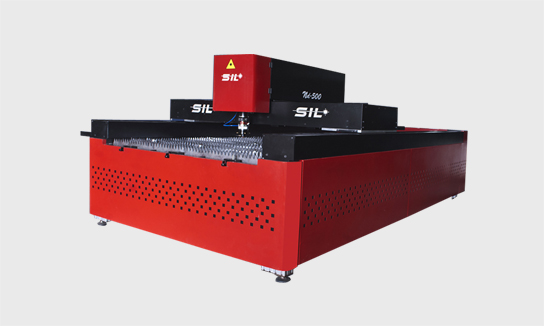

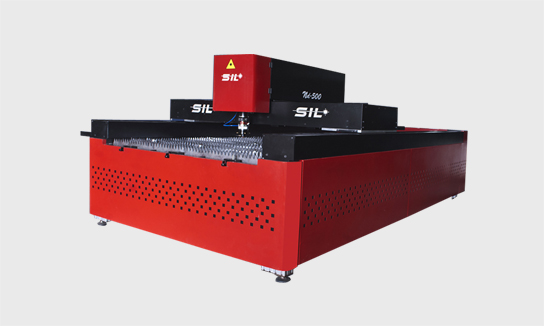

Laser Engraving And Cutting Machine

Applicable Industries:

Signage, Indoor & Outdoor Advertisements, Gifts, Shoes, Toys, Garments, Model cutting, Interior & Decorators, Paper & Packaging, Wood & MDF Cutting Industry, etc

System Features:

- SIL series 1225 large format non-metal laser cutting system

- Special optics for harsh working environments

- High quality industrial chiller, with easy maintenance

- Gantry type structure, high precision imported ball screw system

- Hiwin linear guide rail with stable and high precision transmission

- Light & solid beam structure with superior dynamic performance, modular design

- Offers customized service & economical cutting

- Fixed optical path system ensures consistency of cutting

- Servo motor and drive system technology

- 130 watt DC C02 laser glass tube with 10 months guarantee (150 / 180 Watt laser tube optional)

- Fixed steel strips (honeycomb available on demand)

- DSP based controller for offline work with 32 mb file space

- Red beam pointer

- Twin zone exhaust system

- Engineered for lowest space consumption

- Manufactured in India

Small And Medium Format Laser Engraving Cutting Machine

Applicable Industries: Signage, Indoor & Outdoor Advertisement, Art & Craft, Gift, Shoes, Toys, Garments, Model cutting, Interior & Decorators, Paper & Packaging, Wood & MDF Cutting Industry etc

The range of SIL Series laser engraving and cutting machine models are categorized by different working areas and CO2 laser power.

Hiwin linear guide rail with stable and high precision belt drive system.

X-Y optical path system ensures consistency in cutting.

Latest technology stepper motor and drive system technology.

100 Watt DC C02 laser glass tube with 10 months guarantee (130 /150 Watt laser tube optional)

Aluminium strips working table has wide applicable working options and field can engrave all kinds of non-metallic materials within working area. (optional honeycomb available on demand)

32 bit high speed DSP smart curve controller is designed to improve performance and achieve stable S type acceleration control. Automatic attenuation compensation techniques to achieve the desired result for different cutting parts.

Full opto-coupler isolation system with high-speed differential input and output circuit design, signal is not distorted in long-distance transmission.it can achieve 12 outputs and 16 output status,user friendly interface.

Smart curve controller with USB2.O high speed interface, safer and faster data transmission

Fiber Laser Marking Machine

System Features:

- Accuwrite F-series uses Yb fiber laser technology integrated with a precision beam deflecting unit for marking or micro machining on nearly all metals and non metals.

- The system is compact, efficient and reliable providing the customer the lowest cost of ownership.

- The excellent beam quality and stability, integrated with precision beam deflecting unit, enables Accuwrite F-series to provide, high resolution, fast and clear marking on variety of materials, more so than other laser marking systems available in market.

- The system includes a auto focus Z-axis system, rotary axis (optional) and sophisticated, easy-to-use laser marking / micro machine software, producing marks of various types of shapes, design, bar codes; micro machining to produce die cutting in thin sheets of S. S. Aluminium, Copper Gold etc.

- Accuwrite F comes with a warranty of 1 year. Thanks to the MOPA fiber having no moving parts, and involving tele-communication grade laser diodes as pump source, these are highly reliable components.

- Fiber laser marking machine is a very competent model and uses the most modern tools available in the industry.

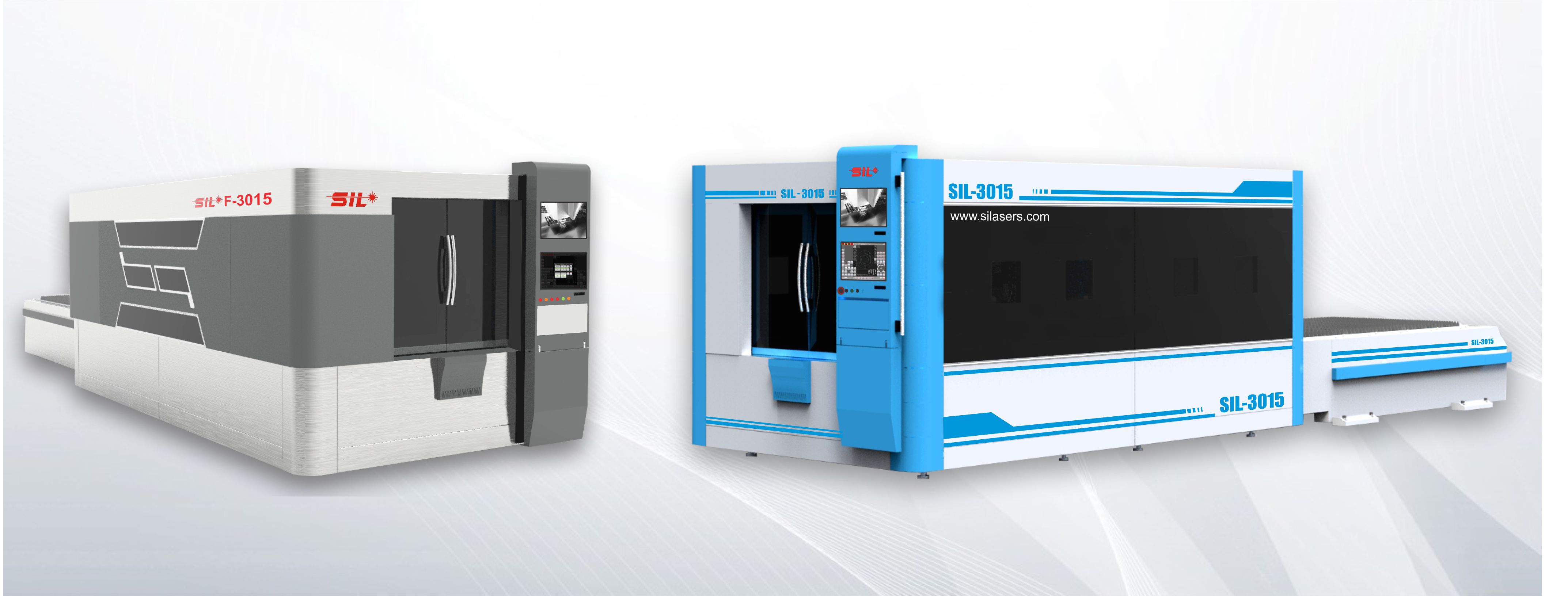

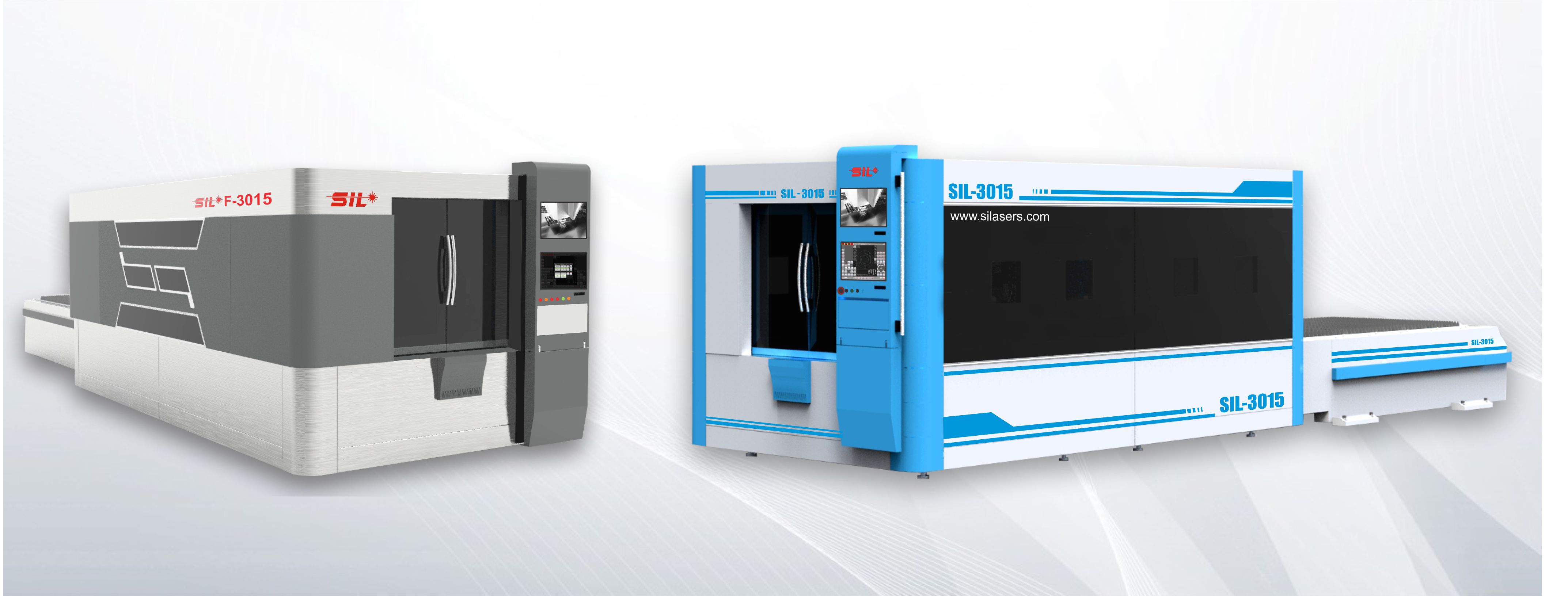

Fiber Laser Metal Cutting Machine

Features

- Type: SIL 1 KW , Fiber laser metal cutting – 3015

- Structure: Gantry, double drive

- Light alloy beam (Y axis) to provide high dynamic performance. The optical path changes while the sheet remains still, thus the processing efficiency is high.

- X, Y axis adopts high quality gear and rack, reduction gear, ensuring life and precision for a long time..

- The system is equipped with section dust collector to improve the working environment. The area beneath the cutting table is divided into several sections. During the cutting process, only the ducts directly beneath the cutting head are open for fume extraction. The ducts in the other sections remain closed to improve dust collection.

- proprietary controller or as demanded by customer.

- Equipped with 1000 Watt fiber laser. Wall-plug efficiency is 30% or higher and no need of gas. The efficiency of cutting within 3 mm thickness is 80% higher than that of CO2 laser. The comprehensive cost is much lower. The transmission of the laser beam depends on the fiber without any mirror. The laser structure is small and compact with high reliability.

Laser Spot Welding Machine

Characteristics

This Nd : YAG laser spot welding machine uses ceramic spotlighting cavity from England that has higher reflectance, higher power, very long life. As a proven model in the market, this machine has mature technology and stable performance, and is a volume-selling machine for over four years.

The machine comes with high power chiller which keep the systems running for longer time. Special long table is provided with ball-Screw based Z- Axis for precision & easy positioning of jobs & also movement during welding

Applications

- Precision injection die-cast, module fixing metal decoration

- Parts precision stamping

- Parts welding

- Fix flushing sluice

- Aluminum casting

- Stainless products

Laser Welding Machine

Features:

- Real time energy feedback loop

- Comparing the actual waveform & setting to achieve a more ideal output waveform

- Progressive Function

- Welder or welding seam-overlapping parts

- Controller

- Controller can be removed from the panel to be operated by hand

- Energy Monitoring Function

- Can be detected by monitoring the Laser power meter (J) and average power (W) output exception

- Wave form control function

- Segments waveforms with basic FIX mode FLEX has the performance of complex waveforms

- External communications

- Detection value for conditions such as ‘SET’ or can be centrally managed

- Variable lens

- To balance / eliminate differences caused by surface Laser energy loss and improve balance quality differences

- High Density

- HP – 2552A can be used for precision high speed seam welding (such as for aluminium battery boxes)

Laser Metal Cutting Machine

Characteristics

This is an indigenously manufactured 600 watt, YAG laser source laser metal cutting machine with high focus optical stability. It is virtually adjustment free and effective in inhibiting the thermal lens effect. It adopts an automatic-focusing and height tracking system to avoid changes in cutting quality that occur due to deformities and bumps in the profile cutting steel sheet.

Low one-time investment, cost-effective, high returns: ideal top priority purchase!

The laser system in this machine is a superior quality indigenous solid state laser technology power 600 watt. It is integrated with a CNC X-Y work Table having ball screw and servo system. The system also includes a precision cutting head.

ADVANTAGES AND APPLICATIONS:

- High precision: applicable for high-precision required part cutting; and precise part cutting for arts and crafts.

- High speed: 100 times faster than linear cutting.

- Small heat affected zone, can not be easily distorted. Cutting edges are very smooth, no need for further processing.

- High cost-performance ratio: only 1/3 of similar CO2 Laser cutting machines and 2/5 of CNC punching machines with similar functions are available at this price point.

- Low maintenance cost

C.N.C Router

1) Excellent speed, efficiency, high precision CNC engraver router machine built in X, Y Axis drive system rack and pinion with 25 mm square linear rails achieving high positioning, motion accuracy & longer life.

2) Working Table with aluminum T-slot and PVC sheet for protection of worktable which ensures for longer life.

3) Optional 1.5 KW /2.2 KW / 3.5 KW / 4.5 KW / 6.0 KW / 7 KW / 9 KW / 12 KW spindles of various power.

4) Handheld DSP controller to set job parameter, and download from computer via USB cable and USB key also.

5) Original italian HSD spindle longer life and guaranteed performance

Laser Cladding Machine

This laser cladding system is probably the first of its kind in India. Featuring a 2.8 KW fiber coupled diode laser and a coaxial powder-feeding nozzle for porosity free, and near crack-free nickel-based coatings; high content globular tungsten carbide (WC) get applied to metal surfaces. The process reduces the operational cost of conventional CO2 systems by at least a factor of three, and lowers investment cost by utilizing smaller laser systems.

Our laser cladding system is extremely compact in size, easy to operate, has high wall plug efficiency, lower investment and running costs for laser cladding; especially in an industrial environment.

The laser cladding principle:

A metal surface-enhancing process performed by applying a powdered metal material on to the base surface, forming a laser bond with minimal dilution, nominal melting and small heat affecting zone.

Laser Optics

SIL optics technology Co., all use CVD Znse, which imported-from USA, materials absorption is lower, our lens can with stand the high power density, and surface is firm, not easy to fall off, resistance to wipe.

Zinc selenide focus lens are widely used in CO2 laser process, including cutting, drilling, carving & other laser system. With the imported material, our products can withstand high power density; and the film is solid, with which the lens are resistant to wipe.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.