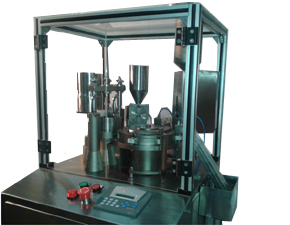

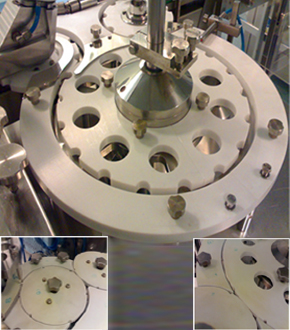

Hand Filling Machine

This is a most versatile machine suitable for all classes of pharmaceutical manufactures providing powder filling machines, capsule filling machines etc. It combines GMP design and construction. The equipment is simple to operate with minimum variation and with negligible rejection. The STD-Model is made of non-corrosive metal with stainless 304 quality for all parts that come into contact with the filling powder.