SHINI PLASTICS TECHNOLOGIES INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SHINI PLASTICS TECHNOLOGIES INDIA P.LTD.

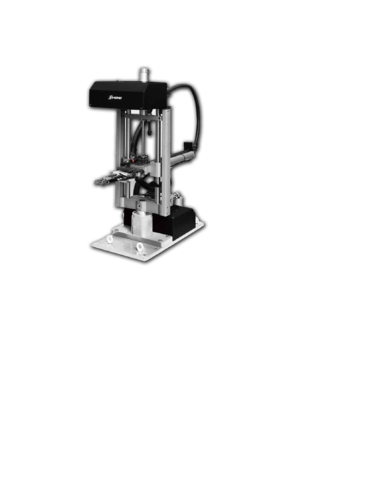

Central Vacuum Generators

Designed to provide high level of vacuum, our range of Central Vacuum Generators is distinguished by its features including durability, powerful, and hassle free longer service life. These attributes also ensure its continuous loading. For its core power, these generators adopt high performance blowers (single- or double-stage) or Roots blowers. Available in more than 11 models with maximum horsepower up to 15 HP suitable for different system applications, the range is offered at industry leading prices.

Central Control Stations Sccs

Introduction the central control stations adopt SIEMENS PLC for conveying materials, monitoring the system and alarming with super and perfect function. This system has a standard device (S7-200PLC) that can support conveying up to 36 molding stations. When equipped with S7-300PLC, it can achieve central monitoring of each station by modularization and fulfill enhancement of molding machines by expansion modularization. It has been designed and built to comply with CE standards ensuring highly safe operations. Colorful touch-screen interface makes operation much easier.

Central Safety Filters Scsf

Introduction The central safety filters adopt a large dust collector to remove the dust and fines from the conveying material so that can effectively protect blower and prolong its service life. Self-cleaning function ensures effective cleaning of filter core depending on a pre-set timing cycle that can avoid manual cleaning inconvenience. Vacuum breaking valve is fitted to reduce loading time and hence accelerate the material conveying capacities.

Central Hopper Receivers Shr Us

Introduction central hopper receivers are a necessity for material loading system. There are 2 types of hopper receivers: hopper mount and machine mount. The hopper mount type can be mounted on top of the drying hopper, the machine mount type can be installed on feed-throat of the moulding machine directly. Vacuum separating valve is fitted on top of the hopper to form a systematic conveying and loading integration.

Material Distribution Stations Smds

Introduction The function of the distribution branches is to distribute materials to the corresponding hopper receivers. They here 5 models of SMDS series, each equipped with quick release couplings, so the loading and unloading of material are convenient. The stainless steel is adopted for build the to eliminate material contamination.

Pet Machine

Introduction With this drying demand and the development on plastic industry, SHINI Group provides a series of secured and reliable drying and dehumidifying technologies for PET molding and other PET product manufacturer. SHINI Group’s PET system has leading technologies in the industry to meet various application needs.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

51164.jpg)

51166.jpg)