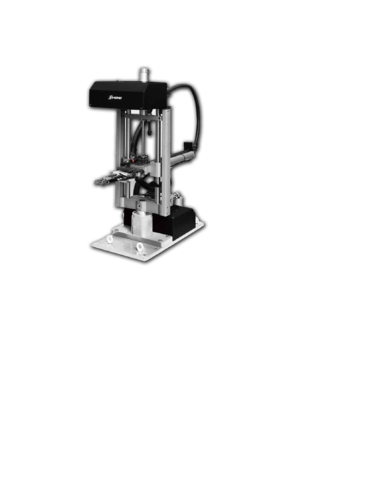

Side Entry Robots

Our domain expertise enables us in offering an exclusive range of Side Entry Robots. Making use of high grade raw material and advanced techniques, the range is designed for extremely short cycle time of IMM less than 6 seconds and under 600T clamp force. Acknowledged for improving the product efficiency, our SSE series employs console model installation, rendering machine height lower, separate from injection moulding machine without mechanical vibration frequency interfere

51164.jpg)

51166.jpg)

51194.jpg)

51197.jpg)

51247.jpg)

51251.jpg)

51252.jpg)

51253.jpg)

51256.jpg)