SHINI PLASTICS TECHNOLOGIES INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SHINI PLASTICS TECHNOLOGIES INDIA P.LTD.

Water Chillers

Together with the efforts of our professionals and advanced techniques, we bring forth high performing Portable Water Chillers. Designed in compliance with industry defined standards, these are applicable for cooling moulds to reduce products moulding cycle. Our range also finds usage in the cooling assembly of the equipment in order to maintain a normal temperature. Stringently checked and tested, the range is ideal to be used in numerous industries because of excellent cooling properties.

Cfc Free Refrigerant Water Cooled Water Chiller

CFC-free Refrigerant Water-Cooled Water Chillers (SIC-W-R2)

SIC-W-R2 series water-cooled cooler adopts single vapour compression circuit and possesses compressor overload protection, pump overload protection, anti-phase and open phase alarm, anti-freeze protection and pressure controller, etc. which all ensure a stable and long-service-life performance. The series of cooler can cool quickly and stably to meet the custumers’ requirements and is worked based on the principle of heat and cold exchange. It is indispensable equipment in modern industry.

Cooling And Heating Temperature Controllers (Stc W)

51194.jpg)

The SIC-W series heaters are applicable to cool, heat and keep constant temperature of moulds. All models are equipped with over-temp. protection, compressor and motor overload protection, phase shortage and reversal alarms, anti-icing protection and high-low pressure protection, etc. They feature stable performance and a long lifespan; also they can fulfill fast heating and cooling according to customers. The series of working flow is based on the basic principle of heat exchange. It is applicable to the industry that requires cooling and heating and it is considered the indispensable equipment for modern industry.

Hi Temp Oil Heaters (Stm Ht

STM-HT series high temperature oil heaters are used to heat up the mould and maintain temperature, although they can be used in other similar applications. High temperature oil from the mould is returned to the cooling tank and cooled by indirect cooling. It is then pressurised by the high - pressure pump, sent to the heating tank and finally to the mould with a constant temperature. With our optimised design, It can reach a maximum of 300 and the HANYOUNG temperature controller can maintain an accuracy of ±1.

Hi Temp. Water Heaters (Stm Hpw)

51197.jpg)

STM-HPW series water heaters have both standard and high temperature models, which are used to heat up the mould and maintain temperature, they can be used in other similar applications as well. High temperature water from the mould is returned to the cooling tank and cooled by either indirect cooling (For high temperature and high temperature plus pressure models) or direct cooling (For standard models). It is then pressurised by the high-pressure pump, sent to the heating tank and finally to the mould with a constant temperature. The OMRON temperature controller can ensure an accuracy of ±0.5.

High Temperature Water Heater Stm Pw

STM- PW/HPW series high temperature water heaters are used to heat up the mould and maintain temperature, although they can be used in other similar applications. High temperature water from the mould is returned to the cooling tank and cooled by either indirect cooling ( For high temperature models ) or direct cooling ( for standard models ). It is then pressurized by the high-pressure pump, sent to the heating tank and finally to the mould with a constant temperature. The HANYOUNG temperature controller can maintain an accuracy of ±1.

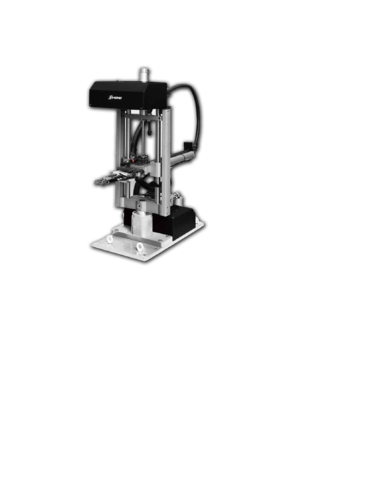

Mold Temperature Controller

The STM series standard oil heaters are used to heat up the mould and maintain this temperature, although they can be used in other similar applications. High temperature oil from the mould is returned to the cooling tank and cooled by indirect cooling. It is then pressurised by the high-pressure pump, sent to the heating tank and finally to the mould with a constant temperature. With our optimised design, oil can reach a maximum of 200 and the HANYOUNG temperature controller can maintain an accuracy of ±1.

Mold Temperature Controllers

STM-W series water heaters are used to heat up the mould and maintain temperature, although they can be used in other similar applications. High temperature water from the mould is returned to the cooling tank and cooled by either indirect cooling (For high temperature models) or direct cooling (for standard models). It is then pressurised by the high - pressure pump, sent to the heating tank and finally to the mould with a constant temperature. The HANYOUNG temperature controller can maintain an accuracy of ±1

Mould Temperature Controlle

STM-E (WE) series are applicable for heating up the moulds and maintaining temperature, and they also can be used in other similar applications. Firstly, these series adopt different cooling methods to cool down mediums, then mediums are conveyed to the moulds after pressurized by pump and heated up by electrical heated tube. The optimal design renders water be heated up to 120 and oil up to 150.

Mould Temperature Controller

STM-WF series 'Large Flow' water heaters are used to heat up the mould and maintain temperature, although they can be used in other similar applications. High temperature water from the mould is returned to the cooling tank and cooled by direct cooling. It is then pressurised by the high-pressure pump, sent to the heating tank and finally to the mould with a constant temperature. The HANYOUNG temperature controller can maintain an accuracy

Water Flow Regulators

SFR series water flow regulators are designed to work with mould heaters, water chillers and cooling towers, which can be connected to more than one mould connectors. They have the function like temperature and flow rate displays, flow rate control in order to meet the requirement of different working conditions. Modularized combination ensures convenient installation and maintenance. It is a necessary device for modern plastic industry to improve its moulding efficiency.

Oil Heaters

We are also involved in manufacturing and supplying Oil Heaters of STM series. Manufactured in both the standard and high temperature models, these are used to heat up the mould and maintain temperature. In addition to these, the range can be used for similar kind of heating applications. The functionality of the heaters starts with the heating of the oil into the moulds, after reaching to high temperature the oil from the mould is returned to the cooling tank and cooled by indirect cooling. After the cooling process the oil is again returned to the heating tank while pressurizing the high-pressure pump. Finally, the oil reaches to the mould with a constant temperature. Manufactured utilizing advanced production technologies, the range reach a maximum of 200 and the HANYOUNG temperature controller can maintain an accuracy of ±1.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

51164.jpg)

51166.jpg)