SHINI PLASTICS TECHNOLOGIES INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SHINI PLASTICS TECHNOLOGIES INDIA P.LTD.

Proportional Valves

Leveraging on our experience and expertise, we bring forth a high performing range of Proportional Valves. Designed with utmost precision, the range mixes regrind and new material in a proper proportion. After the perfect mixing of the content, these valves send the mixed material back to the moulding machine to achieve a proportional mixing and loading effect. Fabricated to directly mount on loaders or on the pipeline, these are suitable to Euro loaders. Further, to make them perform in other situation, it has equip control box.

Plastic Mixers

The Storage Mixers offered by us are designed with an aim to achieve excellent mixing of the material. Further, the range is assembled with screw blades that generate the vortex. The vortex sucks the material towards the mixing screw that is attached at the centre of hopper bottom. After that the material whirls upward to the top and fall down so that the evenly mixing can be fulfilled in a short period. To add strength and minimize material contamination, all the parts that come in contact with material are made of stainless steel.

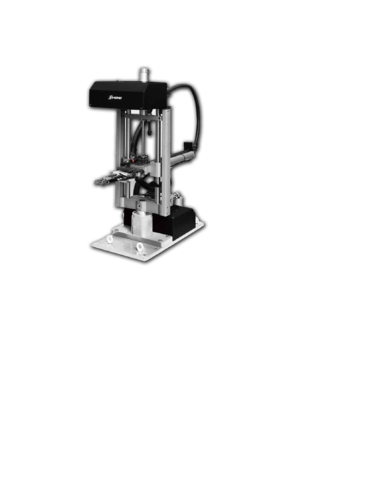

Volumetric Dosers

The SCM-E series "Standard" volumetric dosers are suitable for auto-proportional mixing of new materials, regrinds, master batch and additives. A carbon-brush motor is used in this series. The operator controls the precise dosing screw by setting its rotation speed to extrude materials with an accuracy of ±1%. A gear motor with deceleration ratio of 38:1 or 75:1 is coupled to a dosing screw of 12, 14 or 16mm diameter to give a total of six models with output ranging from 0.1 to 38kg/hr. Double color dosers can be supplied to match with two single color dosers if required by clients.

Vertical Mixers

SVM-U is mainly used for mixing plastics as raw materials, master batch and recycled materials. SVM-U can not be used dealing with plastic powder and all kinds of foods, chemicals, and inflammable, explosive and volatile materials. Bulk density should be taken into account when the dimension of material is uneven or in other forms.

Components Volumetric Dosers

The SCM-4 series 4 Components Volumetric Dosers are suitable for auto-proportional mixing of new materials, regrinds, master batch and additives. A brushless DC motor is used in this series and touch screen plus PLC control are used. The operator controls the precise dosing screw by setting its rotation speed to extrude materials with an accuracy of ±1%. A gear motor with deceleration ratio of 38:1 or 75:1 is coupled to a dosing screw of 12, 14 or 16mm diameter. Clients are free to choose gear motor with different deceleration ratio and different screw diameters.

Gravimetric Blenders

SGB series gravimetric blenders can be used in the fields of injection moulding machines, blow moulding machines and extrusion lines for proportionally precise mixing of several types of material. This series machines adopt SIEMENS PLC controller and latest ingredients calculation methods.The machine is controlled by an advanced microprocessor with a digital display that is simple to calibrate. The self-compensation and calibration function ensure accurate material dosing percentages. A high precision electronic weighing scale is used to ensure precise weighing of every batch and ensure accuracy to ± 0.1%~ 0.3%. There are 42 models available to be selected based on various materials and through puts. (This series are not suitable for powder and sheet pieces weighing)

Metal Separators

SMS series metal detecting separators are highly sensitive and accurate in detecting and separating metal grains, such as steel, iron, copper, aluminium, lead, tin, and so on. Its principle is when metal impurities pass through it, electrical detector can send a signal to control board to start valve to discharge the impurity materials. Pneumatic discharging system takes little space and ensures good performance. It can be installed directly on injection moulding machine or (extruders) hoppers to protect the screw of machine from the damage caused by hard metals. There are three models of the series: SMS-35~70, processing capacity can reach up to 600L/hr~3,000L/hr to meet any specific requirement.

Proportional Valve

SPV-U series proportional valves mix regrind and new materials in a proper proportion, and then send them back to the moulding machine to achieve a proportional mixing and loading effect. It features directly mounted on loaders or mounted on the pipeline. Besides, it is applicable to Euro loaders and has to equip control box to perform when in other situations.

Plastic Batch Mixers

SSM-U is mainly used for mixing plastics as raw materials, master batch and recycled materials. SSM-U can not be used dealing with plastic powder and all kinds of foods, chemicals, and inflammable, explosive and volatile materials. Bulk density should be taken into account when the dimension of material is uneven or in other forms.

Volumetric Colour Dosers

Introduction SCM series volumetric dosers are suitable for auto-proportional mixing of virgin materials, regrinds, master- batch or additives. A gear motor with gear ratio of 38 : 1 or 75:1 is coupled to a dosing screw of 12, 14 or 16mm diameter to give a total of six models with output. ranging from 0.1~32kg/hr. Double color dosers can be assembled from two single color dosers if required. Five components automatic mixing can be realized if customers adopt four color dosers.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

51164.jpg)

51166.jpg)