Asbestos Jointing Sheets

Compressed Asbestos Fibre Jointing is a consistently uniform and resilient product. A price worthy quality of dependable performance, plus adaptability to many sealing requirements makes this 'STEAM' jointing the choice sheet packing or of Plant Engineers and maintenance men.

Spitmaan Style 20 Jointings are developed for general purpose applications and this quality is applicable to a wide range of duties with less severe working conditions of temperature and pressure.

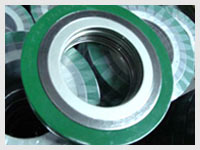

Gaskets 49531.jpg)