SHARP ABRASIVES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SHARP ABRASIVES

Abrasive Grinding Wheels

Description / Specification of Abrasive Grinding Wheels

We are involved in offering a wide range of Abrasive Grinding Wheels to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Abrasive Grinding Wheels. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Straight Grinding Wheels

We at Sharp Abrasives offer a wide range of Firetech Straight grinding wheels; resin bonded grinding wheels and more. These resin-bonded abrasive products have higher tensile strength as compared to the vitrified bonded abrasive products and therefore these straight grinding wheels can withstand heavy grinding pressure and mechanical shocks. The wheels are generally made from a matrix of coarse particles pressed and bonded together to form a solid, circular shape, Various profiles and cross sections are available depending on the intended usage for the wheel. We at Sharp Abrasives manufacture these wheels in a precise and tightly controlled process, that ensures uniform compositon to prevent that disc from exploding due to the high stresses produced on rotation.

Features:

- Higher tensile strength as compared to the vitrified bonded abrasive products

- Capable of running up to 9500 SFPM

- Easy performance

Application:

- The primary function of these straight grinding wheels is for stock-removal such as excessive weld etc.

- Can be applied on bar stock, structural steel, tubing, sheet metal etc.

- Can be applied on various kind of Steel and non-ferrous materials

Reinforced Cut Off Wheel

Firetech Reinforced Cut-off Wheels are reinforced and designed for resisting any breakage caused by heavy cross bending. These resin bonded wheels can be used for any operation where work is not clamped and deepness of cut is on the higher side. Firetech abrasive grinding wheels are available in different full sizes and can be customized for size, grade and more for large quantity. These Cut off wheels, also known as parting wheels, are self-sharpening wheels that are thin in width. They are often used in the construction industry for cutting reinforcement bars (rebar), protruding bolts or anything that needs quick removal or trimming. Most handymen would recognize an angle grinder and the discs they use.

Features:

- Fiber glass reinforced cold pressed depressed centre wheels

- Safely used on portable cut off machine up to speed of 13500 SFPM

- Universally free cutting and resistance to fracture

- Lasting performance

Application:

- Major Industrial and Construction fields.

- Can be applied on bars, structural steel, tubing, sheet metal etc.

- Can be applied on various kind of Steel and non-ferrous materials

Reinforced Depressed Center Grinding Wheels

Firetech Reinforced Depressed Centre Grinding Discs are excellently fabricated depressed center grinding discs that are exclusively available in varying diameters of (100mm to 230mm) in different thickness. These are made of High quality raw material and hence these are able to withstand extreme loads offered by the grinding application with utmost safety. Firetech Reinforced Depressed Center Grinding Discs are resin bonded abrasive wheels. Resin bonded grinding wheels are specially reinforced with fibre glass reinforcements. We, at Sharp Abrasives, are specialized for customizing Reinforced Depressed Centre Grinding Discs.

Features:

- Fiber glass reinforced cold pressed depressed centre wheels

- Capable of running from 13500 to 16000 SFPM

- Ensures a high production ratio with no chances of breakage

- Full performance and maximum endurance

Application:

- Weld – dressing

- Cutting off smoothing of Casting

- Can be applied on various kind of Steel and non-ferrous materials

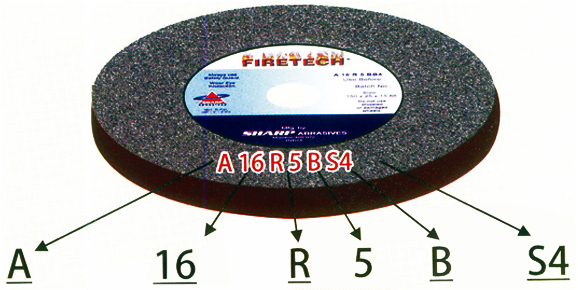

Grinding Wheel Marking

Description / Specification of Grinding Wheel Marking

We are involved in offering a wide range of Grinding Wheel Marking to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Grinding Wheel Marking. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Reinforced Depressed Center Grinding Discs

Description / Specification of Reinforced Depressed Center Grinding Discs

We are involved in offering a wide range of Reinforced Depressed Center Grinding Discs to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Reinforced Depressed Center Grinding Discs. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

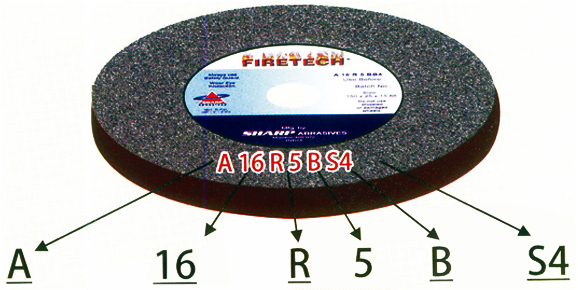

Anatomy Of Wheel

What is a bonded abrasive ?

A resin bonded abrasive is a grinding or cutting tool composed of abrasives grains which are held tightly together by a bonding agent and typically reinforced with a woven material. Within the bonded abrasives category are grinding and cutting wheels, as well as "stones" in a variety of shapes and size.

Three Main Components of Resinoid Bonded Abrasives are as follows:

- Abrasives Grains: Abrasives grains are the Main component of grinding wheels. These are the cutting tools glued in wheels. There are different abrasive but most commonly used are Aluminum Oxide and Silicon Carbide, Alumina Zirconium. Aluminum oxide is used to grind materials such an hard steel Aluminum oxide it the most common abrasive used in grinding wheels. Silicon carbide grinding wheels is used to grind the low tensile strength materials, such an aluminum, brass and softer bronzes, it is also used on most non-ferrous metals. Alumina zirconium is a very fine, dense crystalline grain which can be used for rugged stock removal.

- Bonding Agent: The Bonding agent that hold the grains together determines the resistance of the wheel. There are six types of bonding agents. In the Resinoid bond, synthetic resins are used to unite the grains of the abrasive. A resinoid wheel produces a higher surface finish, and should be run at a higher surface feet per minute.

- Reinforcement: The reinforcement material provides extra strength to use the wheel at miximum RPMs and withstand lateral pressure that is appiled during use. It also increase the life of wheel remarkably.

How Abrasives work?

The function of abrasives is to remove material. The wheel is made up of two components, the abrasives and the bond. The abrasives acts like the cutter and the bond is the glue holding the abrasives grains together. Since the abrasive is harder than the material being ground, each grain acts like a cutting tool.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.