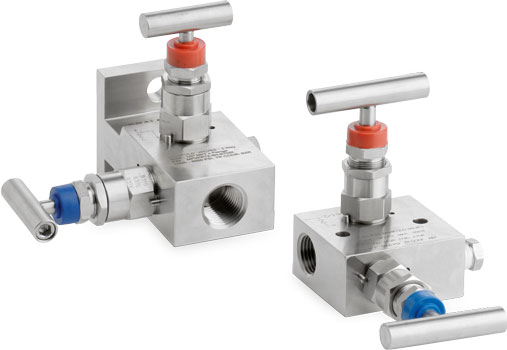

Monoflange Valves

FEATURES

[MANIFOLD VALVES : SERIES - MFV] [MANIFOLD VALVES : SERIES - MFV]

[Stainless Steel 316 Needle Valves] [Stainless Steel 316 Needle Valves]

• Available with OS & Y bolted bonnet, integral screwed bonnet and bolted bonnet design.

• ANSI B16.5 Flanged Inlet Connections 1/2" to 2" Sizes.

• Class 150 rated to Class 2500 rated.

• API Flanged Inlet Connections also available.

• 1/2" - 14 NPT (Female) Standard Outlet.

• 1/4" x 18 NPT (Female) Standard Vent.

• Standard Material of construction: SS316 / SS316L, Carbon

Steel and Duplex.

• Fire Safe designed to meet BS 6755 Part 2/API 607 are

available on request.

• Material Traceability to EN10204 3.1.B (Body only).

• Anti Blow-Out stem & low operating torque.

• Bubble tight shut off seats 17-4 PH tips standard.

• PTFE is a standard Valves Packing, Graphite is also available

on request.

• Every Valve is Factory Tested.

[MONOFLANGE VALVES : SERIES - FMV]

[Stainless Steel 316 Needle Valves] [Stainless Steel 316 Needle Valves]

OPERATING PARAMETERS

APPLICATIONS

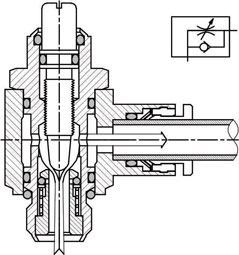

• Double block & bleed instrument isolation.

• Gauge isolation, Instrument drain.

• Chemical injection connection, Sample

connection.

• Chemical seal instrument isolation.

• Piping / instrument interface.

• Direct mounting of instruments.

• Remote mounting of instruments.

Pressure Rating : Class 150 to Class 2500 in accordance with ASME B16.5.

Temperature Rating : Up to 204°C with PTFE Packing.

Up to 428°C with Graphite Packing.

When it comes to the manufacture and design of highly sophisticated valves and fittings for industrial use in a variety of sectors, Sealexcel is a name you can trust! Along with a wide range of product fittings, we also offer superior quality industry standard compliant Monoflange valves, which are designed to withstand industrial operations and ensure smooth processes without error.

Our Monoflange valve series comes with highly sophisticated design features, which have earned us a reputable and reliable name in the industry. We are recognized as reliable Monoflange Valve Manufacturers, who deliver what we promise to all our clients.

Key Features of Our Monoflange Dbb Valve Fittings

Our product design and manufacturing process is in accordance with all industry specified standards, and we take pride on being Monoflange Valve Suppliers who only offer the very best in product to our industrial customers.

Our Monoflange Dbb valve comes with the following technical design features

The 316 Monoflange valves are available in a number of designs, which include, the Y bonnet, bolted bonnet, integral screwed bonnet and OS bolt design

Valves have been designed to withstand a pressure rating of around 6000 PSIG.

The temperature rating of the valves is up to 232⁰C.

All units are verified to be factory tested products

Product rating is Class 150 to around Class 2500 rated

The valves have a flanged inlet connection available in a choice of 1/2 to around 2 inches in size

Our standard material for construction is duplex, carbon steel and SS316/SS316L

Fire safe units designed as per the BS 6755 Part 2/API 607 rule, are also made to order

Our standard Monoflange valve packing is PTFE.

The valves are available in API and ANSI B16.5 flanged inlet connections designs

Units are designed and manufactured with a low operating torque

Monoflange valves come complete with an anti-blow-out stem

Valves are manufactured with a special bubble tight shut off seat that comes with a 17-4 PH standard tip

The standard valve outlet configuration is 1/2 inch x 14 NPT

Standard valve vent configurations are designed to be 1/4 inch x 18 NPT

Graphite packing is also made available on industry client request

Valve is designed with a stainless steel lever

Monoflange Valves Industrial Applications

The Monoflange valve fittings are ideal for industrial applications which include,

• In Situ Calibration,

• Remote instrument mounting

• Instrument drain and gauge isolation

• Chemical injection,

• Instrument isolation,

• Double block and bleed valve instrument isolation

• Direct instrument mounting

• Piping or instrument interface

• Inline process isolation and

• Process sampling procedures.

The Sealexcel Monoflange valves have been designed as a choice and suitable alternative to the conventional multiple valve installations, which are used for the purpose of an interface when working with different pressure measuring systems. We ensure superior quality product design and manufacture, to offer all our industrial clients with precision instruments for sophisticated applications.