SEALEXCEL INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SEALEXCEL INDIA P.LTD.

Bleed Valves

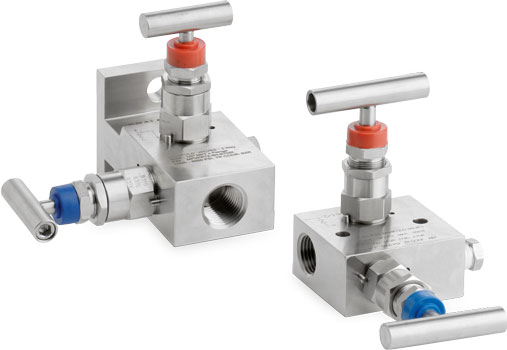

Double Block and Bleed Valves

FEATURES

[Stainless Steel 316 Bleed Valves] [Stainless Steel 316 Bleed Valves]

• ANSI B16.5 Flanged Inlet Connections 1/2" to 2" Sizes.

• Class 150 rated to Class 2500 rated.

• API Flanged Inlet Connections also available.

• 10 mm and 15 mm Full bore Valve design.

• 1/2" - 14 NPT (Female) Standard Outlet.

• 1/4" x 18 NPT (Female) Standard Vent, 1/2" x 14 NPT

(Female) optional vent.

• Standard Material of construction: SS316 / SS316L, Carbon

Steel and Duplex.

• Fire Safe designed to meet BS 6755 Part 2/API 607 are

available on request.

• Material Traceability to EN10204 3.1.B (Body only).

• Anti Blow-Out stem & low operating torque.

• Valves are available with Packing, PTFE, PEEK or Graphite.

• Bubble tight shut off.

• Every Valve is Factory Tested

[Integral Block & Bleed Valves : Series Dbb31]

OPERATING PARAMETERS

Pressure Rating : Class 150 to Class 2500 in

accordance with ASME B16.5.

Temperature Rating : Up to 204°C.

APPLICATIONS

• Double block & bleed instrument isolation.

• Gauge isolation, Instrument drain.

• Chemical injection connection, Sample connection.

• Chemical seal instrument isolation.

• Piping / instrument interface.

• Direct mounting of instruments.

• Remote mounting of instruments.

[BLEED VALVES : SERIES - BLV] [BLEED VALVES : SERIES - BLV]

[BLEED VALVES : SERIES - BLV] [BLEED VALVES : SERIES - BLV]

We at Sealexcel are committed to offer nothing but the very best in valves and fittings when it comes to our customers. We take pride in only offering state of the art designed fittings which have been manufactured with precision and technical finesse to ensure quality operations in all types of work settings.

We serve the industry as reliable Double Block and Bleed Valve Manufacturers, who have a repute for offering nothing but the most durable units, designed to perfection. We take care to uphold our credible position in the market by using latest technology to offer updated product features that ensure high end precision and industrial safety. Our Double Block and Bleed Valves are part of our product portfolio, and are designed to conform to industry standard requirements and our own high design etiquette.

Features of the Dbb Valves Our integral block and bleed valve series Dbb31 is available with the following great features,

Product body designed with a material traceability feature corresponding to EN 10204 3.1.B

Units are designed with a fire safety feature upon request by customers. These units are manufactured to meet the BS 6755 Part 2/API 607 feature.

The standard female unit outlet size is 1/2 inch x 14 NPT

The female standard vent design has a standard dimension of 1/4 inch x 18NPT. The optional vent measures up to 1/2 inch x 14 NPT.

Our Double Block and Bleed Valves are available with a class 150 rating up to class 2500 rating

The Double Block and Bleed Valve unit has a full bore valve design, available in 10mm and 15mm measurements.

Our range of ANSI B16.5 units of flanged inlet connections are available in a size range of 1/2 inches to around 2 inch in size.

Units have been designed with a low operating torque feature

Each Double Block and Bleed Valve is designed with an anti-blow out stem feature, which ensures seal integrity in all kinds of pressures

Units are manufactured with a bubble tight shut off design feature

Unit has durable 316 stainless steel handles, which come with a quarter turn feature, that is designed to resist rust even in offshore settings and due to exposure to different environmental and industry factors

The ddb valve has a temperature rating of up to 204⁰ C.

Double Block and Bleed Valve Applications

Sealexcel is a recognized name in the industry as reliable Double Block and Bleed Valves Suppliers, and we offer products with diverse industry application features which include,

• Remote instrument mounting

• Sample and chemical injection connection

• Instrument drain

• Gauge isolation

• Instrumental or piping interface

• Instrument isolation for chemical seal procedures

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.